A self-supporting membrane electrode, battery and vehicle

A self-supporting film and electrode technology, applied in the direction of batteries, battery electrodes, secondary batteries, etc., can solve the problems of flexible control of thickness, high integration without modules, and continuous film formation of fragments, so as to improve battery energy density, The effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

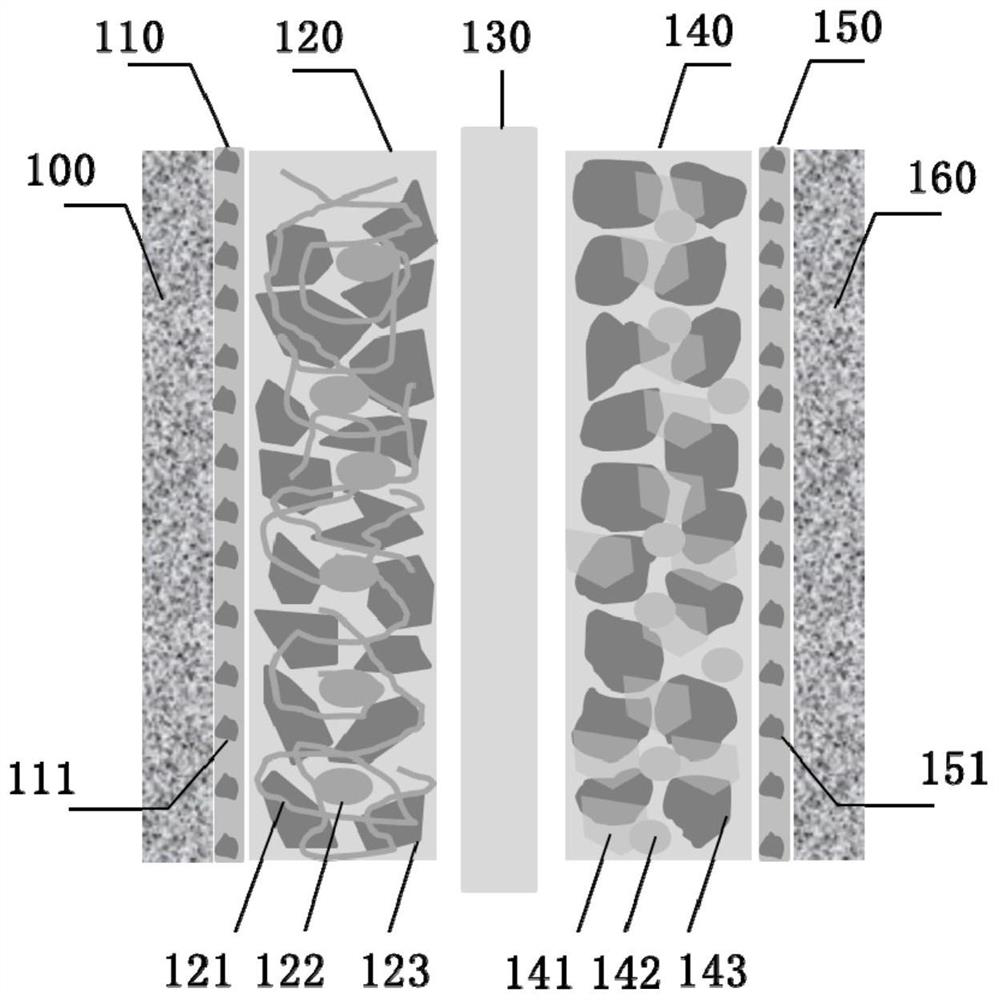

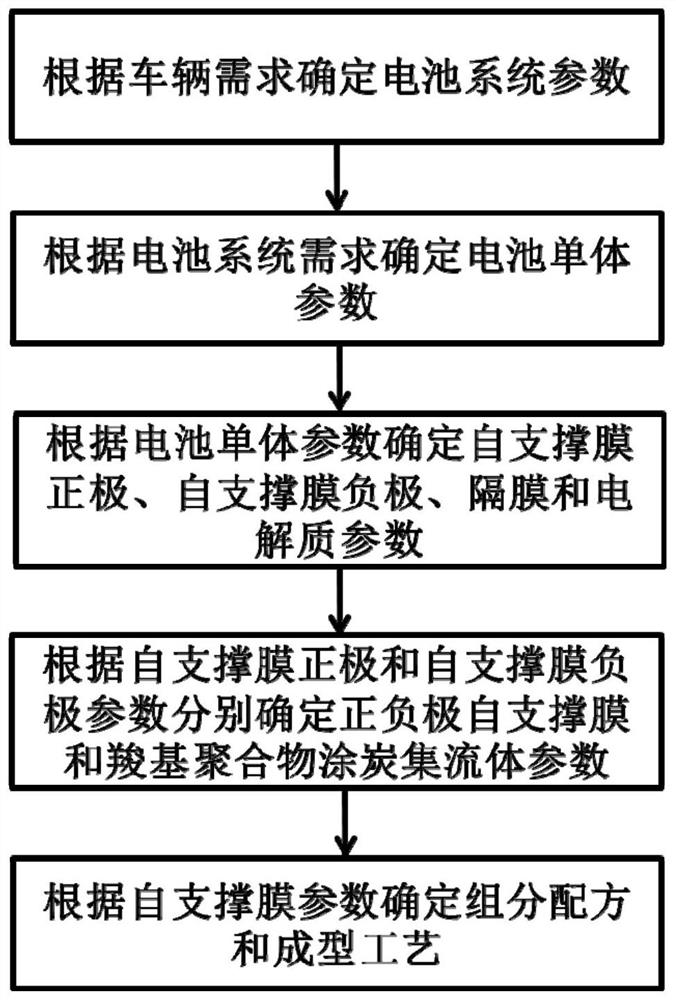

[0130] This embodiment provides a kind of figure 1 The battery based on the self-supporting film electrode, the battery preparation step is as figure 2 As shown, the self-supporting film electrode is produced by the following method:

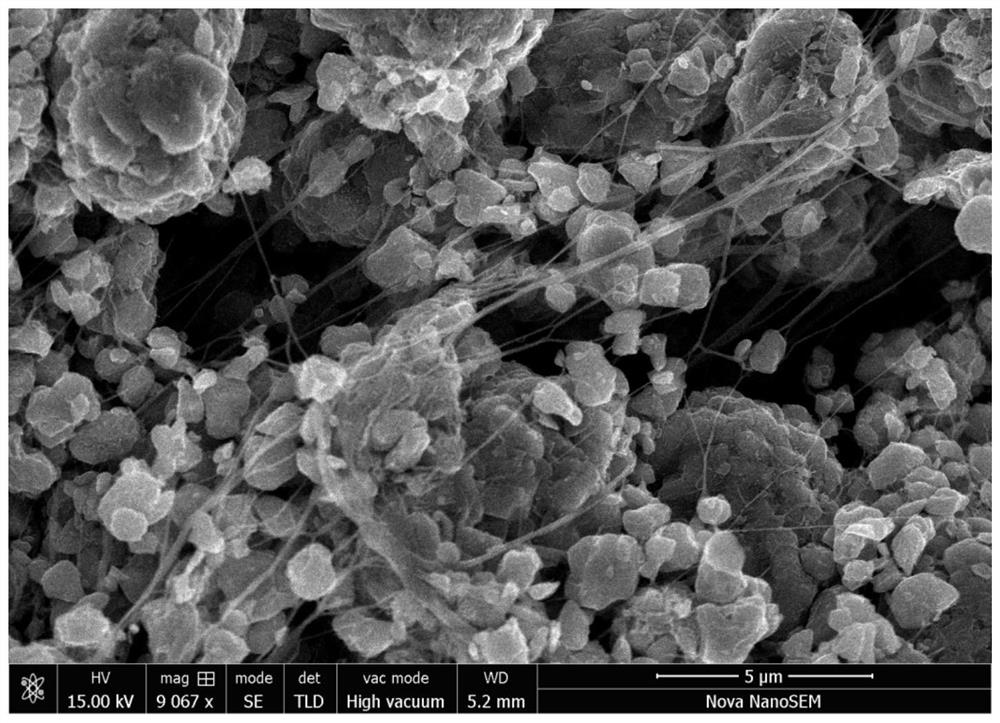

[0131] (1) Nickel-cobalt-manganese (lini) with 94% mass fraction 0.8 CO 0.1 Mn 0.1 O 2 Examples of the active substance, mixed with 2% graphite conductive agent, mixed with a 4% elongation of 300%, compression ratio 300, glass transition temperature of 130 ° C, melting point of 380 ° C, molecular weight of 4 million 4 FF atom polymer binders, mixed 2 h, forming a multi-component mixture having a binder invisible, and mixed 0.5 min in a mixture of 0.5 min in a solvent-free mixture. , Mixture scanning electron microscopy image 3 As shown, the powdered mixture is mixed 20 ° C for 20 min to form a granular coating; the obtained granular coating 120 ° C derived a continuous positive electrode self-support film having a thickness of 120 μm, such as Figure...

Embodiment 2

[0135] This embodiment provides a battery based on the self-supporting film electrode, the self-supporting film electrode to be produced by the following method:

[0136] (1) Quality fraction is 92% active material nickel-cobalt manganese (LINI) 0.5 CO 0.2 Mn 0.3 O 2 ) And 2% graphite conductive agent, mixed at 10 ° C for 1 h, adding 6% elongation of 300%, compression ratio 300, glass transition temperature of 130 ° C, melting point of 380 ° C, molecular weight of 4 million) 4 F fluoro Atomic polymer binder, -5 ° C mixing 1 h, a component mixture having an intangible adhesive invisible, and mixing the obtained multi-component mixture 95 ° C for 1 min to prepare a powdery mixture, powdered mixture 30 EtOAc EtOAc EtOAc m. Made from the positive electrode of the self-supporting film;

[0137] (2) The mass fraction is 97% active material graphite and 1.5% graphite conductive agent, mixed for 1 h at 30 ° C, and the 1.5% molecular segment repeating unit contains 1 nitr-based group, the ...

Embodiment 3

[0140] This embodiment provides a battery based on the self-supporting film electrode, the self-supporting film electrode to be produced by the following method:

[0141] (1) Quality fraction is 96% active material nickel-wateng-cobalt manganese (Lini) 0.6 CO 0.2 Mn 0.2 O 2 ) And 2% graphite conductive agent, mixed at 10 ° C for 1 h, adding 2% elongation of 300%, compression ratio 300, glass transition temperature of 130 ° C, melting point of 380 ° C, molecular weight of 4 million) 4 F fluoro Atomic polymer binder, -8 ° C mixing 1 h, a component mixture having an intangible binder invisible, and mixed 1min of the obtained multi-component mixture 85 ° C for 1 min to prepare a powdery mixture, powdered mixture 30 EtOAc EtOAc EtOAc m. Made from the positive electrode of the self-supporting film;

[0142] (2) The mass fraction is 97% active material graphite and 1.5% graphite conductive agent, mixed for 1 h at 30 ° C, and the 1.5% molecular segment repeating unit contains 1 nitr-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com