Winding battery cell, preparation method thereof and winding battery

A cell, white area technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of limiting the energy density of winding batteries, waste of anode sheet materials, etc., to increase battery energy density, reduce area, The effect of high load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

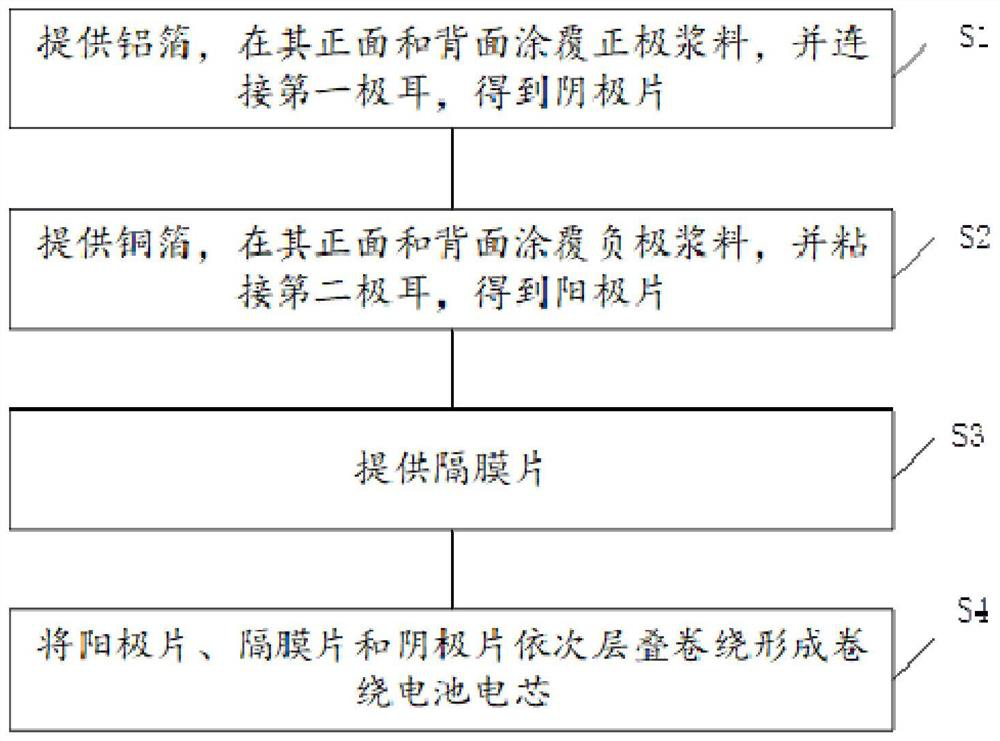

[0044] see figure 1 , the invention provides a method for preparing a wound electric core, comprising:

[0045] S1: Provide aluminum foil 11, coat the positive electrode slurry on the front and back, and connect the first tab 13 to obtain the cathode sheet 1;

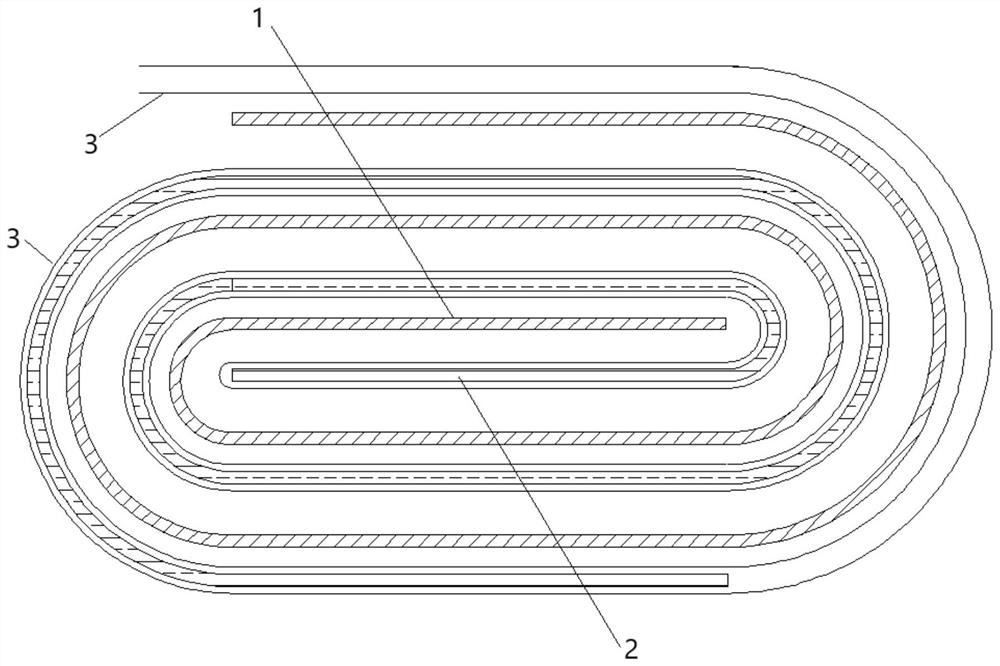

[0046] see image 3 , Figure 4 The front of the cathode sheet is provided with a first positive electrode slurry coating area 12 and a first blank area 14, and the back of the cathode sheet 1 is provided with a second positive electrode slurry coating area 16 and a second blank area 15. The first blank area 14 and the second blank area 15 are arranged at the winding end of the cathode sheet 1 .

[0047] Wherein, the width of the first blank area 14 and the second blank area 15 is the same as that of the aluminum foil 11, which is 60-70 mm. The lengths of the first blank area 14 and the second blank area 15 are the same, being 25-35 mm, exemplarily 26 mm, 29 mm, 32 mm, 35 mm, but not limited thereto. The first blan...

Embodiment 1

[0076] This embodiment provides a winding cell:

[0077] (1) provide the aluminum foil that width is 67mm, this aluminum foil is coated positive electrode slurry on its front and back side, and connects first tab, obtains cathode sheet,

[0078] Among them, the positive electrode slurry is made by mixing 90wt% LiNi0.5Co0.2Mn0.3O2, 5wt% Super P, and 5wt% pvdf, adding NMP solvent (60% of the mass of the first three substances) and stirring for 4 hours.

[0079] Wherein, the front side of the cathode sheet is provided with a first positive electrode slurry coating area and a first blank area, and the back side of the cathode sheet is provided with a second positive electrode slurry coating area and a second blank area. The first blank area and the second blank area are arranged at the winding end of the cathode sheet. The length of the first positive electrode slurry coating area and the second positive electrode slurry coating area is 1200mm; the length of the first blank area ...

Embodiment 2

[0090] This embodiment provides a winding cell:

[0091] The difference between embodiment 2 and embodiment 1 is;

[0092] The first positive electrode slurry coating area of the cathode sheet is provided with a through hole with an aperture of 0.7 mm and a distance of 2 mm between adjacent through holes; the first negative electrode slurry coating area of the anode sheet is provided with an aperture of 0.7 mm, and the distance between adjacent through holes is 2mm.

[0093] The wound battery made of the wound battery cell of Example 2 has an energy density of 289.97wh / kg through an electrolytic transformer regulator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com