A kind of foam iron reinforced aluminum matrix composite material with high temperature wear resistance and preparation method thereof

A composite material and reinforced aluminum-based technology, which is applied in the field of aluminum alloys, can solve the problems that the wear resistance needs to be strengthened, and achieve the effects of improving impact resistance, improving high temperature wear resistance, and hindering the expansion of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

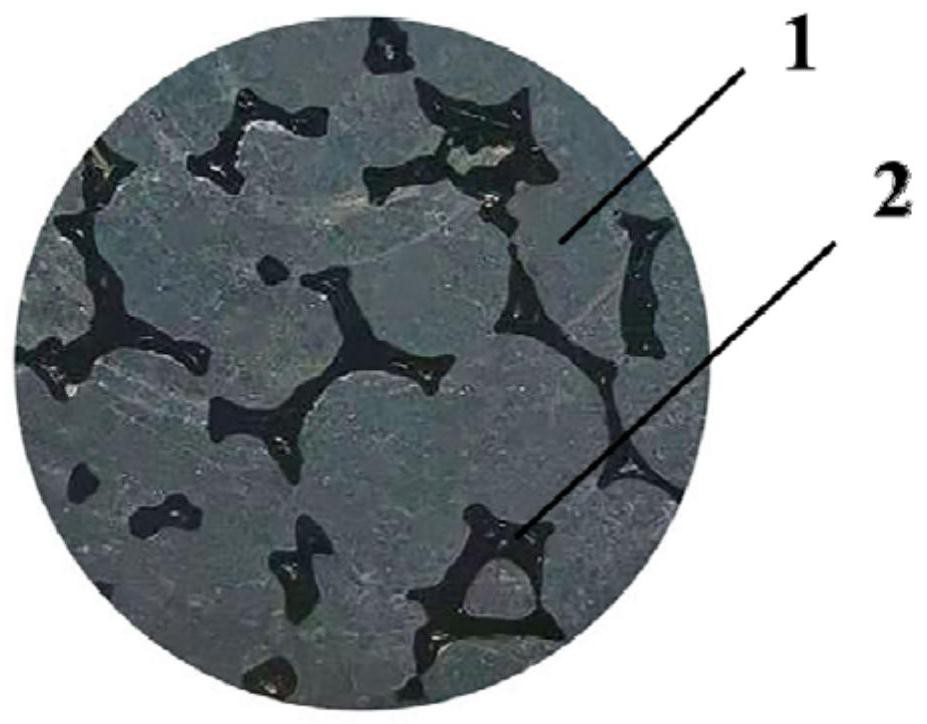

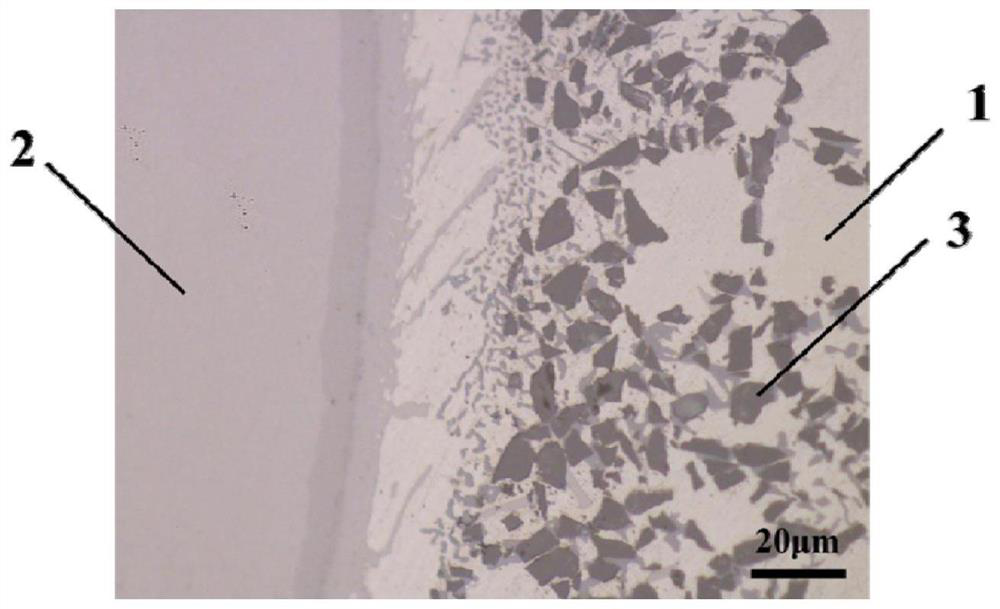

[0043]A foamed iron-reinforced aluminum matrix composite material with high temperature wear resistance, which is composed of a matrix alloy and a reinforcement phase. The matrix alloy is a reinforced aluminum alloy with aluminum alloy as the matrix and micron-sized SiC particles as the reinforcement material. The reinforcement phase is three-dimensional Skeleton through-hole foam iron; and the foam iron and matrix alloy form a network interweaving and interpenetrating structure in three-dimensional space. The composition percentage of aluminum alloy is as follows: Si 8.5-9.5%, Fe 0-0.2%, Cu 0-0.2%, Mg 0.4-0.65%, Ti 0-0.2%, Al balance; SiC particle size is 10-20μm, The volume percentage of SiC particles is 10%.

[0044] Foamed iron reinforced aluminum matrix composites are prepared by the following steps, which include:

[0045] Step 1, cleaning and oxidation treatment of SiC particles:

[0046] s1, use deionized water to ultrasonically clean the SiC particles, and use an el...

Embodiment 2

[0065] A foamed iron-reinforced aluminum matrix composite material with high temperature wear resistance, which is composed of a matrix alloy and a reinforcement phase. The matrix alloy is a reinforced aluminum alloy with aluminum alloy as the matrix and micron-sized SiC particles as the reinforcement material. The reinforcement phase is three-dimensional Skeleton through-hole foam iron; and the foam iron and matrix alloy form a network interweaving and interpenetrating structure in three-dimensional space. The composition percentage of aluminum alloy is as follows: Si 8.5-9.5%, Fe 0-0.2%, Cu 0-0.2%, Mg 0.4-0.65%, Ti 0-0.2%, Al balance; SiC particle size is 10-20μm, The volume percentage of SiC particles is 15%.

[0066] Foamed iron reinforced aluminum matrix composites are prepared by the following steps, which include:

[0067] Step 1, cleaning and oxidation treatment of SiC particles:

[0068] s1, use deionized water to ultrasonically clean the SiC particles, and use an e...

Embodiment 3

[0087] A foamed iron-reinforced aluminum matrix composite material with high temperature wear resistance, which is composed of a matrix alloy and a reinforcement phase. The matrix alloy is a reinforced aluminum alloy with aluminum alloy as the matrix and micron-sized SiC particles as the reinforcement material. The reinforcement phase is three-dimensional Skeleton through-hole foam iron; and the foam iron and matrix alloy form a network interweaving and interpenetrating structure in three-dimensional space. The composition percentage of aluminum alloy is as follows: Si 8.5-9.5%, Fe 0-0.2%, Cu 0-0.2%, Mg 0.4-0.65%, Ti 0-0.2%, Al balance; SiC particle size is 10-20μm, The volume percentage of SiC particles was 20%.

[0088] Foamed iron reinforced aluminum matrix composites are prepared by the following steps, which include:

[0089] Step 1, cleaning and oxidation treatment of SiC particles:

[0090] s1, use deionized water to ultrasonically clean the SiC particles, and use an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com