Thin film, preparation method thereof and quantum dot light-emitting diode

A quantum dot luminescence, quantum dot technology, applied in luminescent materials, chemical instruments and methods, nano-optics, etc., can solve the problem of unbalanced carrier injection, affecting device performance, etc., to improve the injection balance, high-speed conduction, improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

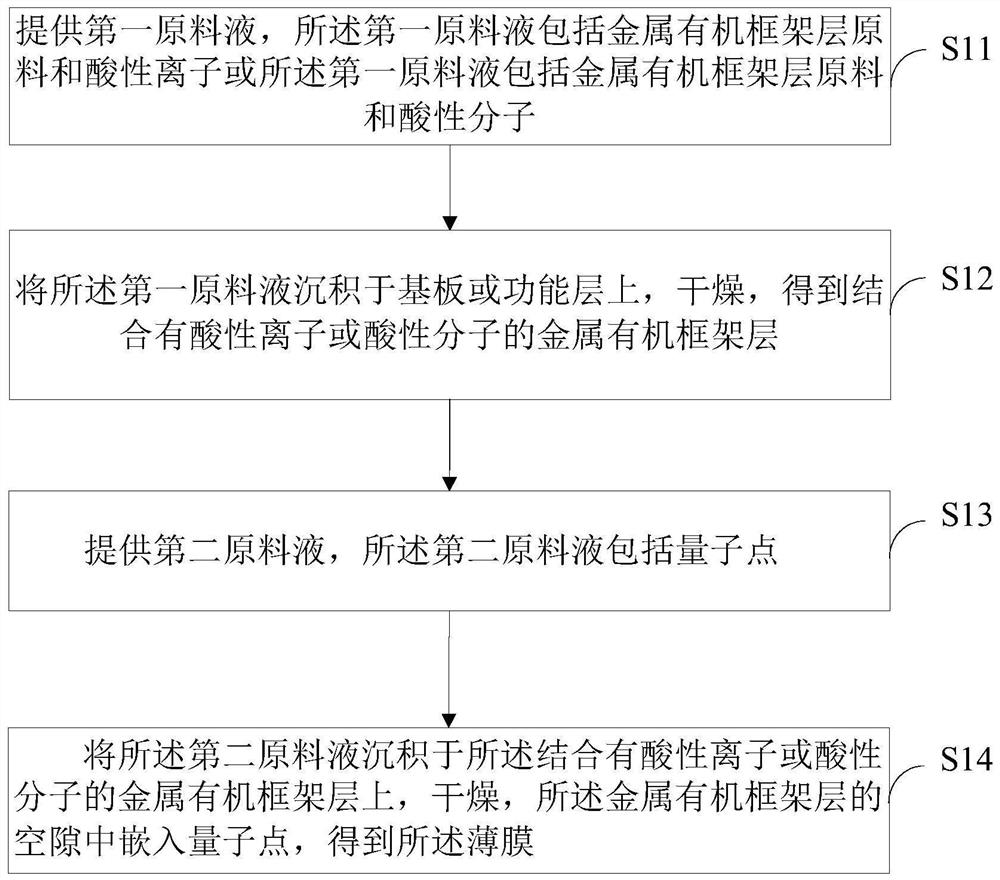

[0070] Preparation of MOFs composite quantum dot luminescent film with acidic groups bonded to the main frame:

[0071] Provide acidic metal-organic frameworks [(CH 3 ) 2 NH 2 ][Y(C 2 o 4 ) 2 (H 2 O)] 3H 2 The raw material solution of O: Y(NO 3 ) 3 ·6H 2 O (3.83g, 0.01mol) and dimethylamine hydrochloride (2.04g, 0.025mol) were dissolved in 50mL of water, and under stirring, it was added dropwise to oxalic acid (2.52g, 0.02mol) and dimethylamine hydrochloride In 50mL aqueous solution of salt (2.04g, 0.025mol), an acidic MOF [(CH 3 ) 2 NH 2 ][Y(C 2 o 4 ) 2 (H 2 O)] 3H 2 O raw material solution.

[0072] Take 80 μl of the above raw material solution and add it dropwise on the substrate, spin it at 3000rpm for 40s, and finally bake it at 80°C for 30mins to form an acidic metal organic framework layer with a thickness of 20nm.

[0073] Provide the raw material solution of blue luminescent quantum dots (CdSe / ZnS) with toluene as the solvent concentration of 30mg / m...

Embodiment 2

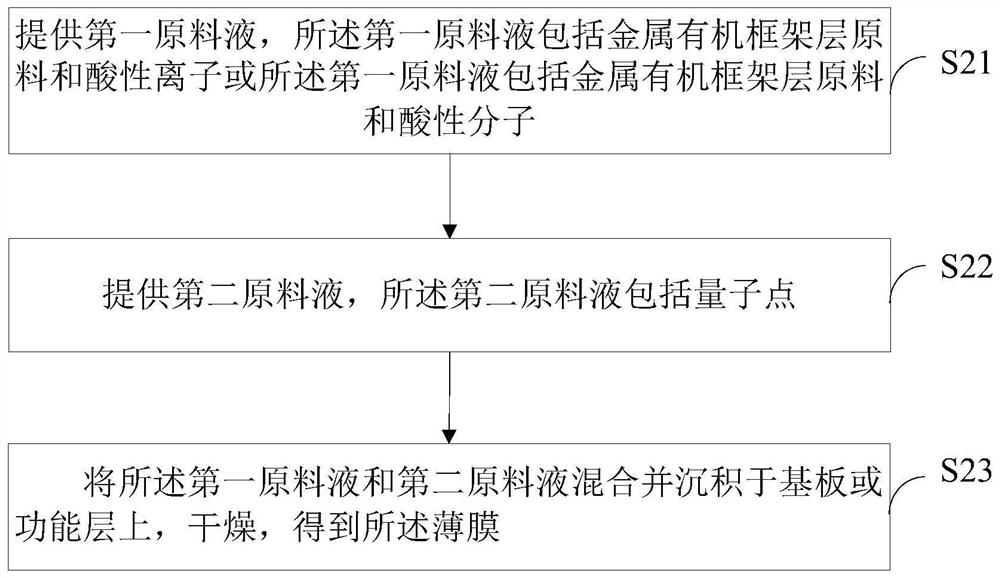

[0075] Preparation of MOFs cavity-loaded benzenesulfonic acid composite quantum dot luminescent film:

[0076] Take 60 mg of zinc oxide powder and add it to 1 ml of formic acid-water solution (including 0.5 ml of formic acid), and then add 0.5 ml of ammonia water to it to obtain a clear solution and form a metal organic framework raw material solution.

[0077] Take 80 μl of the above raw material solution and add it dropwise on the substrate, spin it at 4000rpm for 40s, and then bake it at 80°C for 30mins to form a metal organic framework layer with a thickness of 20nm.

[0078] 100 μl of benzenesulfonic acid was added dropwise on the metal organic framework layer, rotated at 2000rpm for 80s, and then baked at 50°C for 60mins to form a metal organic framework layer loaded with benzenesulfonic acid in the cavity.

[0079] Provide the raw material solution of red luminescent quantum dots (CdSe / Zne) with toluene as the solvent concentration of 30mg / ml, take 50μl of the above raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com