Polymeric polyether intermediate, star polymer containing polybasic phosphate ester group, and preparation method and application thereof

A technology of star-shaped polymer and polyphosphate ester, which is applied in the field of star-shaped polymer and its preparation, can solve the problems of short retarding time, inability to achieve long-term retarding of concrete, and affecting the development of concrete strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

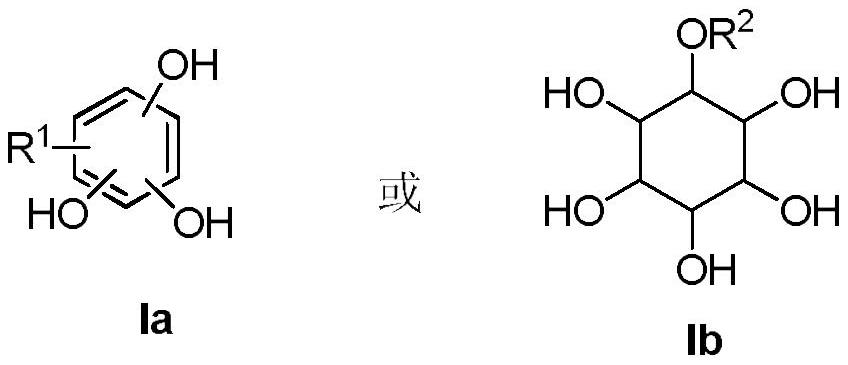

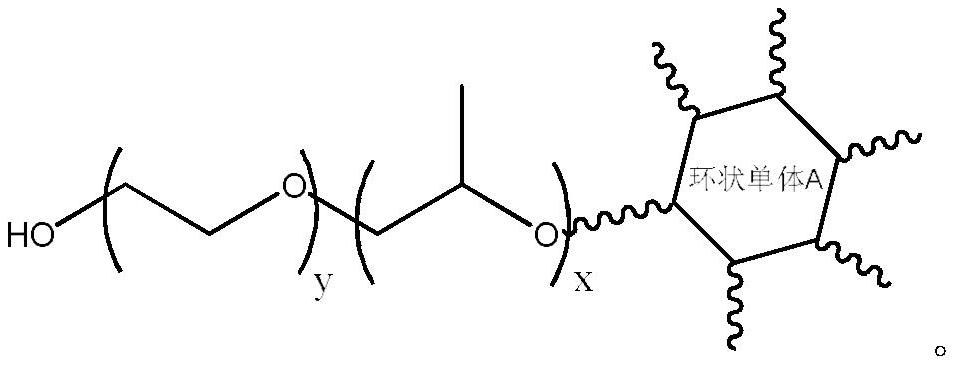

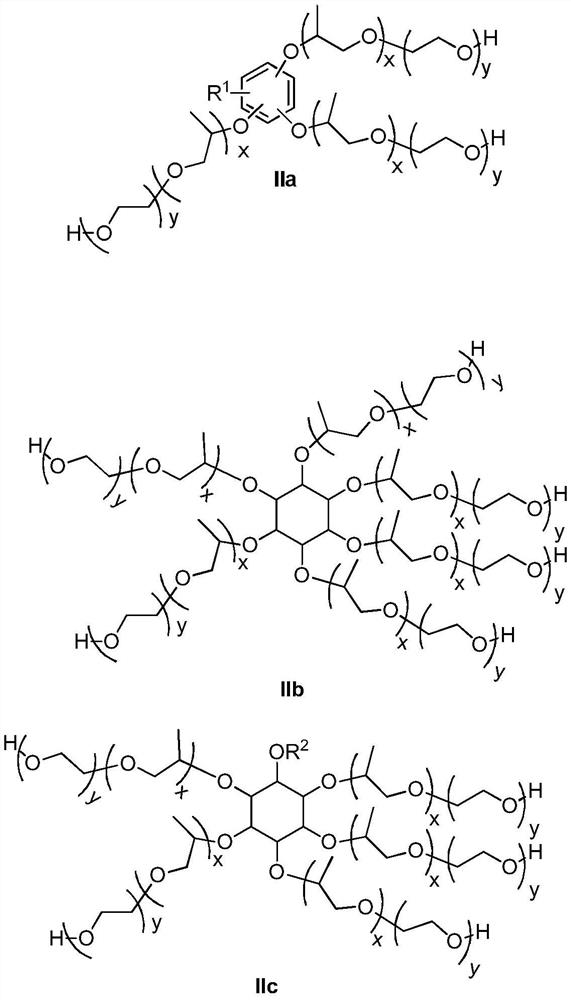

Method used

Image

Examples

Embodiment 1

[0059] The preparation of polyvalent polyether intermediate M-1 (M w =1216, x / y=2 / 10)

[0060] Take by weighing cyclohexyl alcohol 180g (M w =180, 1mol) into the autoclave reactor, add DMC catalyst 0.40g (0.40wt.% of the substrate), anhydrous o-xylene 40g, after stirring evenly, under the condition of -0.08MPa~-0.1MPa, pump Vacuum for 0.5h to remove water and a little volatile components in the raw materials and air. Subsequently, the temperature was raised to about 80°C, and 20g of propylene oxide was introduced to trigger. When the temperature rose and the pressure dropped significantly, 96g of propylene oxide was continued to be passed slowly, the temperature was maintained at 120-135°C, and the pressure was maintained at 0.2-0.3MPa. Propylene oxide is completely reacted (pressure reduced to 0MPa), and 20g of ethylene oxide is introduced to trigger. When the temperature rises and the pressure drops significantly, the remaining 420g of ethylene oxide is slowly introduced, ...

Embodiment 2

[0072] In a 2L three-necked flask, install the upper water separator, add M-1 (0.1mol, 73.6g), N-1 (0.8mol, 528g), p-toluenesulfonic acid (5.52g), o-xylene (100g), After stirring evenly, raise the temperature to 120-130°C to carry out the first-stage esterification reaction. The reaction is kept warm for 8-10 hours. During the reaction, the water generated in the reaction is continuously separated by a water separator. After the first stage of esterification, the solvent toluene in the reaction was separated (the solvent and the product were separated, and the solvent was above). Then remove the water separator in the reaction device, carry out the second-stage esterification reaction, raise the temperature to 150-170°C, keep the temperature for 8-24 hours, use an oil pump to carry out vacuum distillation, and continuously extract the water generated in the second stage of the reaction. After the reaction, cool down to 50°C-70°C, add a certain amount of water and liquid caust...

Embodiment 3

[0074] In a 2L three-necked flask, install the upper water separator, add M-2 (0.1mol, 140.8g), N-1 (0.8mol, 528g), p-toluenesulfonic acid (10.8g), o-xylene (120g), After stirring evenly, raise the temperature to 120-130°C to carry out the first-stage esterification reaction. The reaction is kept warm for 8-10 hours. During the reaction, the water generated in the reaction is continuously separated by a water separator. After the first stage of esterification, the solvent toluene in the reaction was separated (the solvent and the product were separated, and the solvent was above). Then remove the water separator in the reaction device, carry out the second-stage esterification reaction, raise the temperature to 150-170°C, keep the temperature for 8-24 hours, use an oil pump to carry out vacuum distillation, and continuously extract the water generated in the second stage of the reaction. After the reaction, cool down to 50°C-70°C, add a certain amount of water and liquid caus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com