A kind of stable synthetic method of ton zeolite

A synthesis method and zeolite technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve problems such as unfavorable industrial production, and achieve the effects of reducing the severity of the reaction, reducing the production cost, and improving the synthesis success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Obtaining Mother Liquor of Primary Crystallization of TON Zeolite

[0037] Refer to the synthesis method of US5783168 patent to prepare TON zeolite molecular sieve, and to recover the mother liquor by primary filtration.

[0038] The specific operation is as follows: under stirring conditions, 0.38g Al 2 (SO 4 ) 3 18H 2 O was dissolved in 30g of water, then 0.9g of KOH was added, and a clear solution A was formed after fully stirring; 2.5g of 1,6-hexanediamine (DAH) was weighed and added to solution A. 10g silica sol (containing SiO 2 30% by mass), after stirring, a uniform gel B is formed; its specific composition is (molar ratio) SiO 2 : 1.00Al 2 o 3 : 14.00K 2 O: 38.60DAH: 3610H 2 O=88.00:1.00:14.00:38.60:3610.

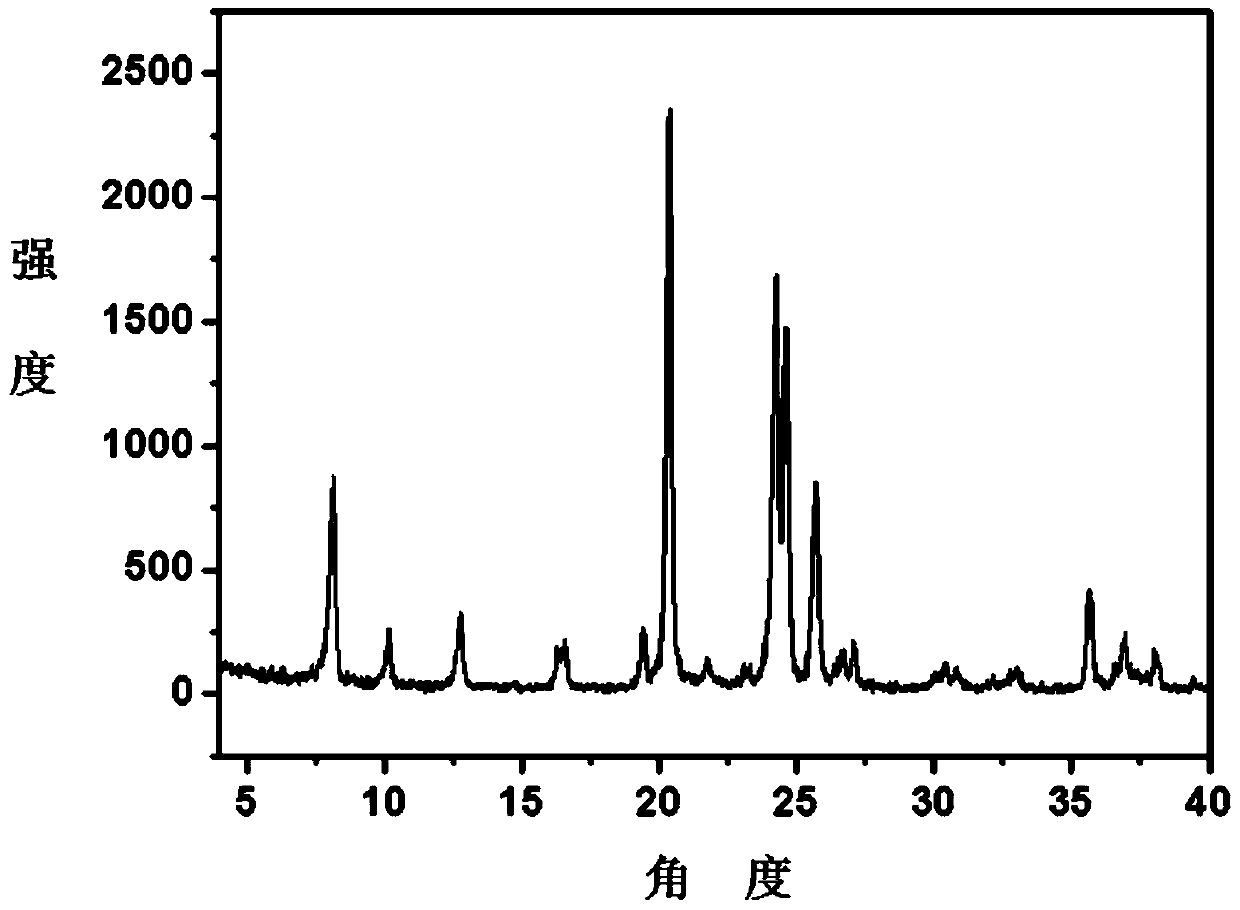

[0039] The gel B was transferred to a 100 mL stainless steel reactor with a polytetrafluoroethylene liner, and the hydrothermal reaction was carried out at 160 °C with a stirring rate of 400 rpm for 48 h. After cooling, the product was filtered at...

Embodiment 2

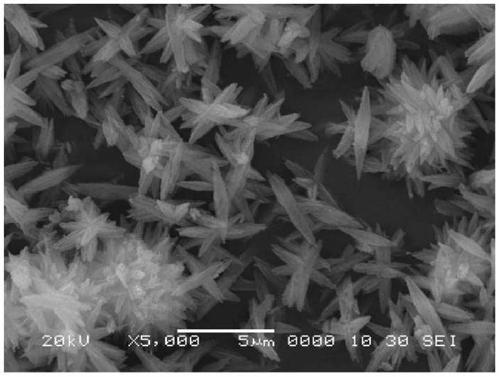

[0041] 160°C, reaction for 42 hours, 15% mother liquor usage, static synthesis of TON molecular sieve

[0042] Gel B was prepared as described in Example 1. Its specific composition is (molar ratio) SiO 2: 1.00Al 2 o 3 : 14.00K 2 O: 38.60DAH: 3610H 2 O=88.00:1.00:14.00:38.60:3610. Then, TON zeolite with 15% of the total mass of gel B was added thereto to filter the mother liquor once. After stirring, a uniform gel C is formed. The gel C was transferred to a 100mL stainless steel reactor with a polytetrafluoroethylene liner, and hydrothermally reacted at 160°C for 42h under static conditions. After cooling, the product was filtered at room temperature to obtain 2.6 g of the product. According to XRD characterization, the product is pure TON zeolite molecular sieve. image 3 shown.

Embodiment 3

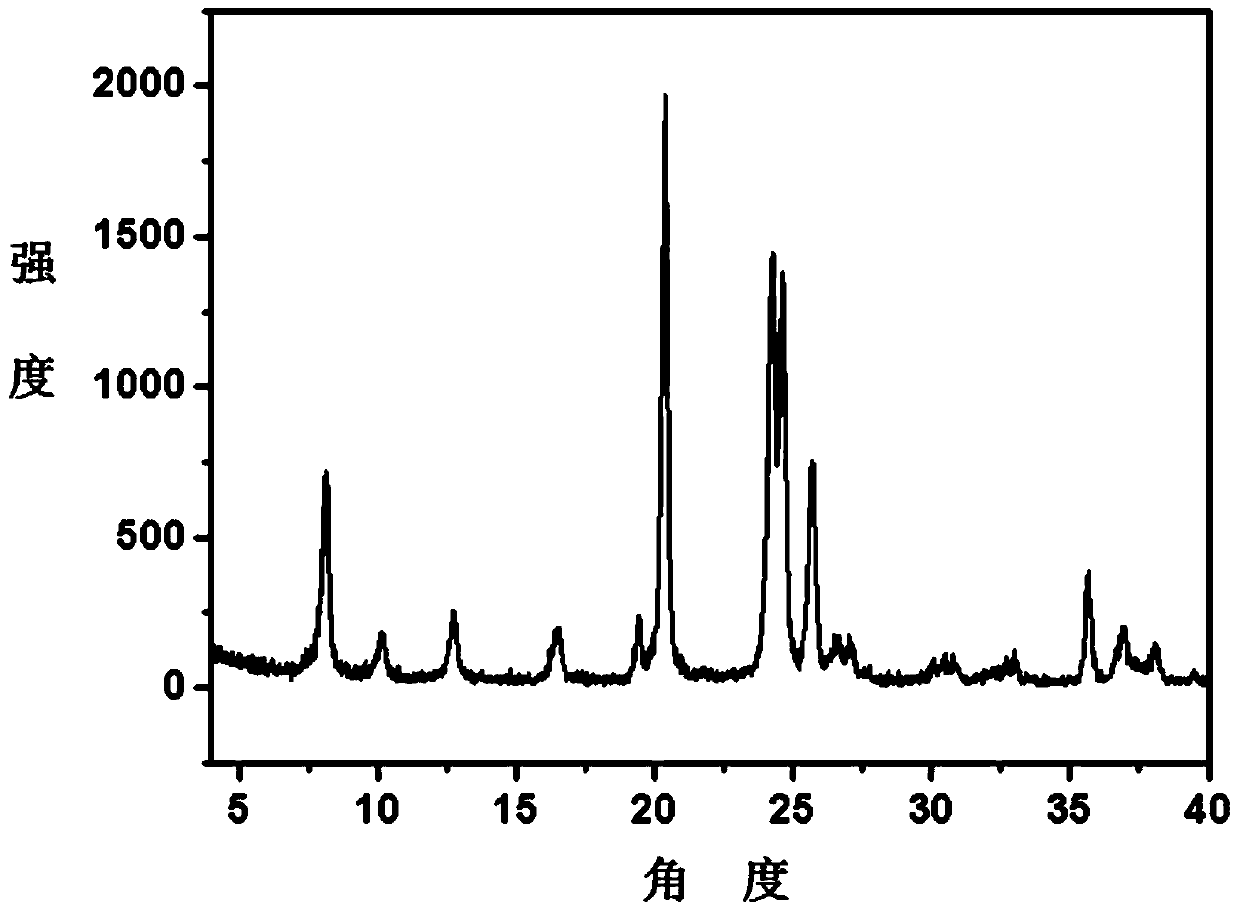

[0047] 160°C, reaction for 42 hours, 20% mother liquor usage, static synthesis of TON molecular sieve

[0048] Gel B was prepared as described in Example 1, wherein the silicon source was silica and the aluminum source was pseudoboehmite. Its specific composition is (molar ratio) SiO 2 : 1.00Al 2 o 3 : 14.00K 2 O: 38.60DAH: 3610H 2 O=88.00:1.00:14.00:38.60:3610. Then add TON zeolite with 20% of the total mass of gel B to it and filter the mother liquor once. After stirring, a uniform gel C is formed. The gel C was transferred to a 100mL stainless steel reactor with a polytetrafluoroethylene liner, and hydrothermally reacted at 160°C for 42h under static conditions. After cooling, the product was filtered at room temperature to obtain 2.6 g of the product. According to XRD characterization, the product is pure TON zeolite molecular sieve. Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com