Activated carbon activation furnace with gas guide structure

A technology of activated carbon and activation furnace, which is applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc. It can solve the problems of inability to activate, short service life, small contact area between steam and activated carbon, etc., and achieves easy automatic sealing and good sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

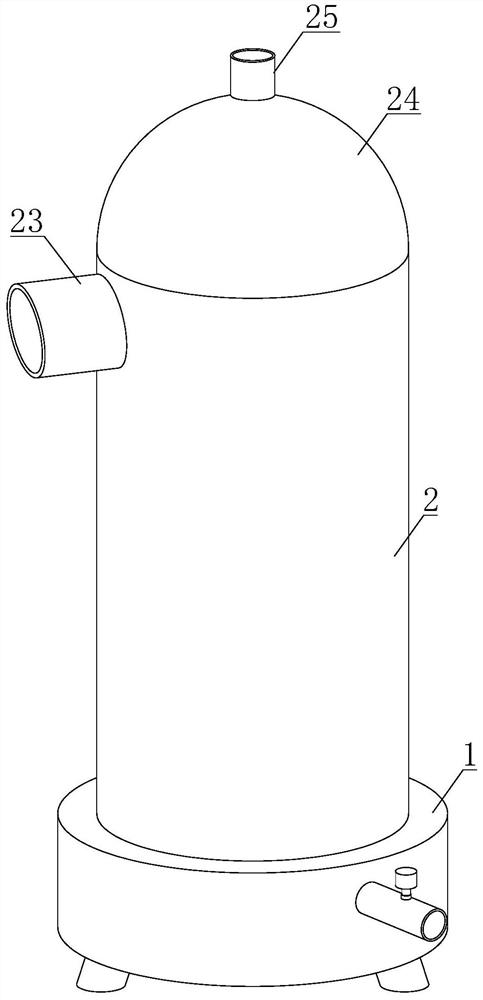

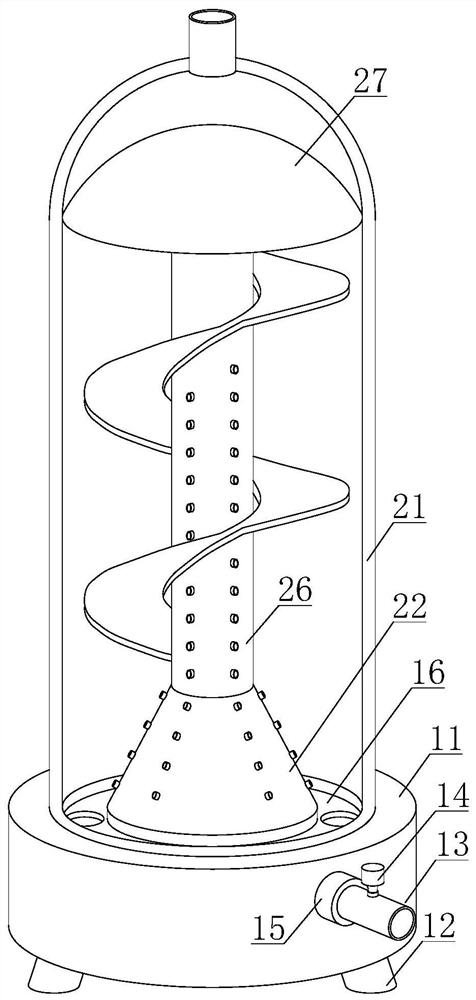

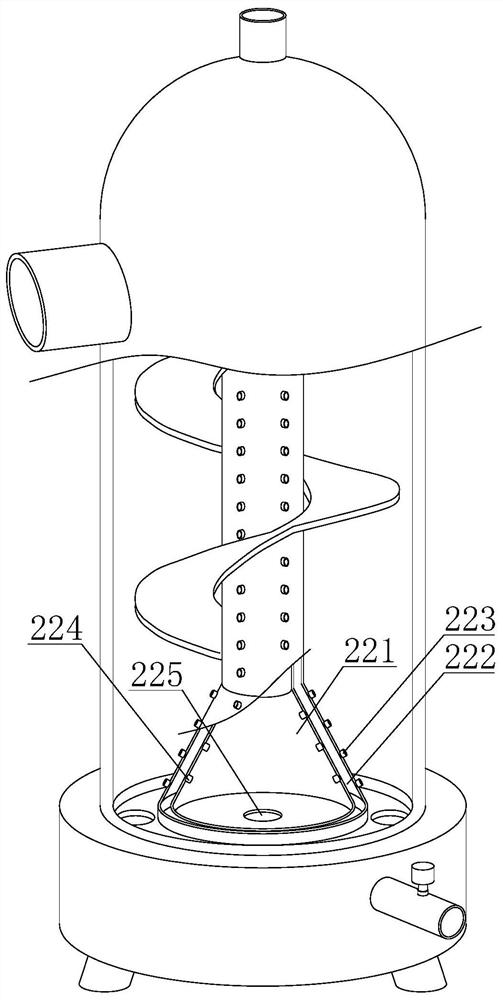

[0029] See figure 1 with figure 2 The active carbon activation furnace having an air conductive structure, including the base 1 and the furnace body 2, the base 1 includes a mount 11, a support post 12, a water pipe 13, a gas pump 14, a water valve 15, and a lumen 16, a mount 11 The lower end is fixedly installed with the support column 12, and the water pipe 13 is connected to the stop valve 15, and is connected to the mount 11, the air pump 14 is mounted on the upper end of the water pipe 13, and the inner cavity 16 is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com