Method and system for producing insoluble sulfur

A production system and production method technology, applied in the direction of climate sustainability, sulfur preparation/purification, sustainable manufacturing/processing, etc., can solve the problems of complex operation process, low yield, poor thermal stability of insoluble sulfur, etc. Simplify the process flow, reduce production costs and avoid the effect of quenching water drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific situation of the present invention will be further described below through specific examples, but not limited to the following examples.

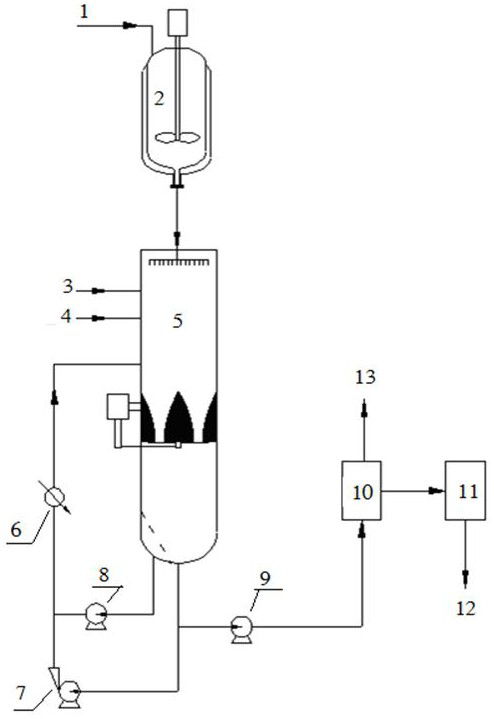

[0043] Such as figure 1 As shown, the present invention provides an insoluble sulfur production system. Described production system comprises polymerizing kettle 2, quick cooling tower 5, washing filter 10 and drier 11; Described polymerizing kettle 2 outlets are communicated with quenching tower 5 inlets through pipeline, and quenching tower 5 outlets are passed through pipeline The discharge pump 9 communicates with the feed port of the washing filter 10, and the discharge of the washing filter 10 is connected to the feed port of the drier 11 through a pipeline.

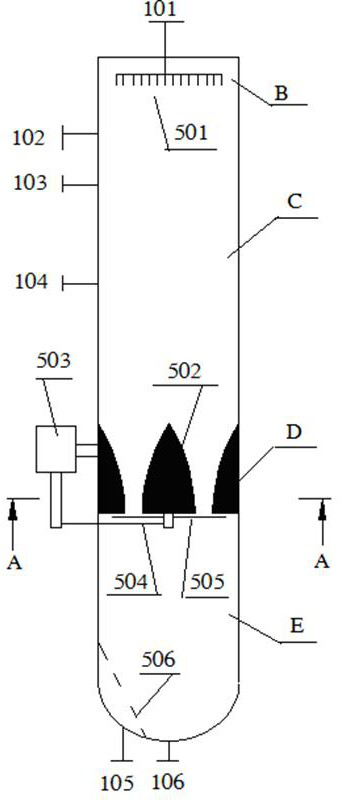

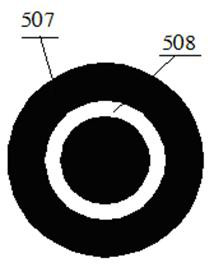

[0044] Such as figure 2 , image 3 As shown, in the insoluble sulfur production system of the present invention, the quench tower 5 includes a shell, and the inside of the shell includes a feeding section B, a quenching section C, a pelletizing section D,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com