Antistatic anti-radiation graphene modified fiber fabric and preparation process thereof

A graphene modification and preparation technology, applied in the direction of conductive/antistatic filament manufacturing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of not having antistatic and radiation resistance, and achieve improved hand feeling and water resistance , light weight, improve the effect of health care

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

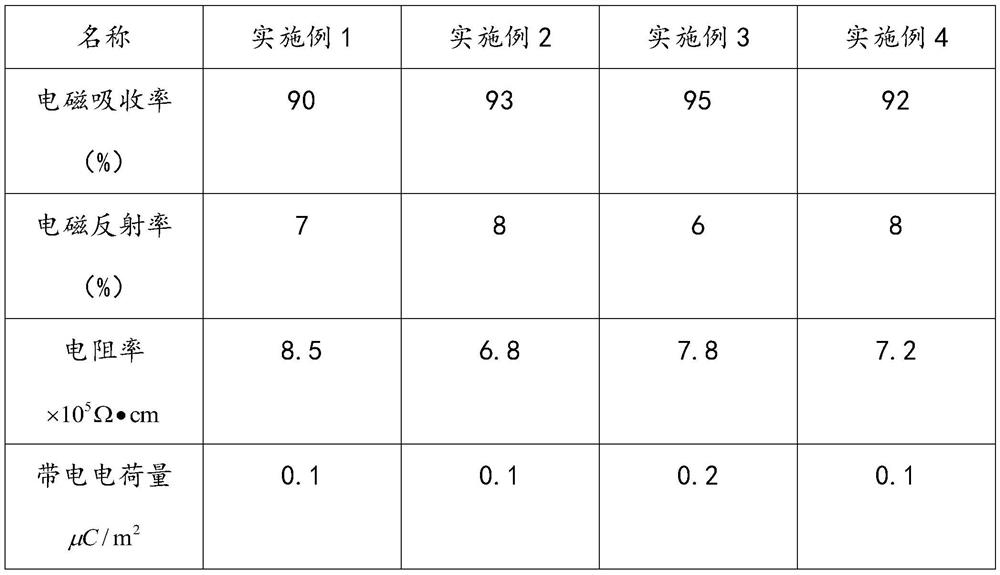

Examples

Embodiment 1

[0028] An antistatic and anti-radiation graphene modified fiber fabric, including a polyester fiber layer, the polyester fiber layer is woven from polyester filaments, the polyester fiber layer is dyed with antibacterial additives in a high temperature environment, and the polyester fiber layer has a graphene modified fiber layer. The fiber fabric layer, the graphene modified fiber fabric layer is made of the following raw materials in parts by weight: 30 parts of polyvinyl chloride resin, 5 parts of azodicarbonamide, 5 parts of aloe vera gel, 3 parts of nano-ceramic absorbent, 3 parts of nano-conductive Polymer 5, nano-chitin 3, germanate 6 parts, graphene oxide 8 parts, talcum powder 7 parts, plasticizer 3 parts, germanate is sodium germanate, zinc germanate, copper germanate among them A sort of.

[0029] A kind of preparation technology of antistatic radiation-proof graphene modified fiber fabric, comprises the following steps:

[0030] a. Place polyvinyl chloride resin, ...

Embodiment 2

[0032] An antistatic and anti-radiation graphene modified fiber fabric, including a polyester fiber layer, the polyester fiber layer is woven from polyester filaments, the polyester fiber layer is dyed with antibacterial additives in a high temperature environment, and the polyester fiber layer has a graphene modified fiber layer. The fiber fabric layer, the graphene modified fiber fabric layer is made of the following raw materials in parts by weight: 25 parts of polyvinyl chloride resin, 6 parts of azodicarbonamide, 7 parts of aloe vera gel, 4 parts of nano ceramic absorbent, nano conductive Polymer 6, nano-chitin 5, germanate 8 parts, graphene oxide 9 parts, talcum powder 8 parts, plasticizer 4 parts, germanate is sodium germanate, zinc germanate, copper germanate among them A sort of.

[0033] A kind of preparation technology of antistatic radiation-proof graphene modified fiber fabric, comprises the following steps:

[0034] a. Place polyvinyl chloride resin, azodicarbon...

Embodiment 3

[0036] An antistatic and anti-radiation graphene modified fiber fabric, including a polyester fiber layer, the polyester fiber layer is woven from polyester filaments, the polyester fiber layer is dyed with antibacterial additives in a high temperature environment, and the polyester fiber layer has a graphene modified fiber layer. The fiber fabric layer, the graphene modified fiber fabric layer is made of the following raw materials in parts by weight: 38 parts of polyvinyl chloride resin, 8 parts of azodicarbonamide, 9 parts of aloe vera gel, 5 parts of nano-ceramic absorbent, and 5 parts of nano-conductive Polymer 7, nano-chitin 6, germanate 10 parts, graphene oxide 13 parts, talcum powder 9 parts, plasticizer 4 parts, germanate is sodium germanate, zinc germanate, copper germanate among them A sort of.

[0037] A kind of preparation technology of antistatic radiation-proof graphene modified fiber fabric, comprises the following steps:

[0038] a. Place polyvinyl chloride r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com