Natural beverage turbid agent and preparation method thereof

A turbidity and beverage technology, applied in the field of natural beverage turbidity agent and its preparation, can solve the problems of restricting commercial large-scale application, food safety without safety assessment of raw material sources, and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

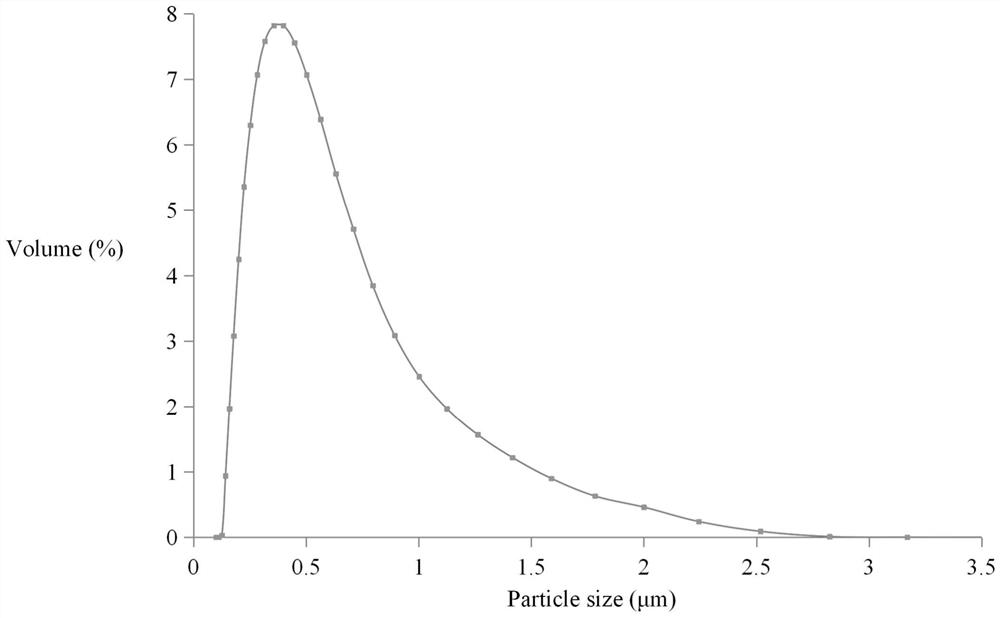

Embodiment 1

[0044] Natural beverage emulsifying agent A, all calculated by weight percentage, material is equipped as follows:

[0045] Emulsified water phase raw materials: 12.6wt% gum arabic, 0.8wt% Quillaja bark extract, 0.4wt% xanthan gum, 1.2wt% phospholipid, 0.8wt% citric acid, 0.2wt% malic acid, 2wt% lactic acid;

[0046] Emulsified oil phase raw materials: coconut oil 14wt%, rosemary extract 0.04wt%;

[0047] Ethanol 4wt%, balance is distilled water.

[0048] The preparation method is as follows:

[0049] Step (1): Fully dissolve gum arabic and xanthan gum in water in proportion, then add soap bark extract, phospholipids, citric acid, malic acid, and lactic acid in proportion and mix them, and let stand until the hydration is complete , through 1-3 times of disc separation, after each disc separation, take a sample and put it into a centrifuge tube for 10 minutes at a centrifuge speed of 3000rpm to observe the impurities at the bottom of the centrifuge tube, preferably without i...

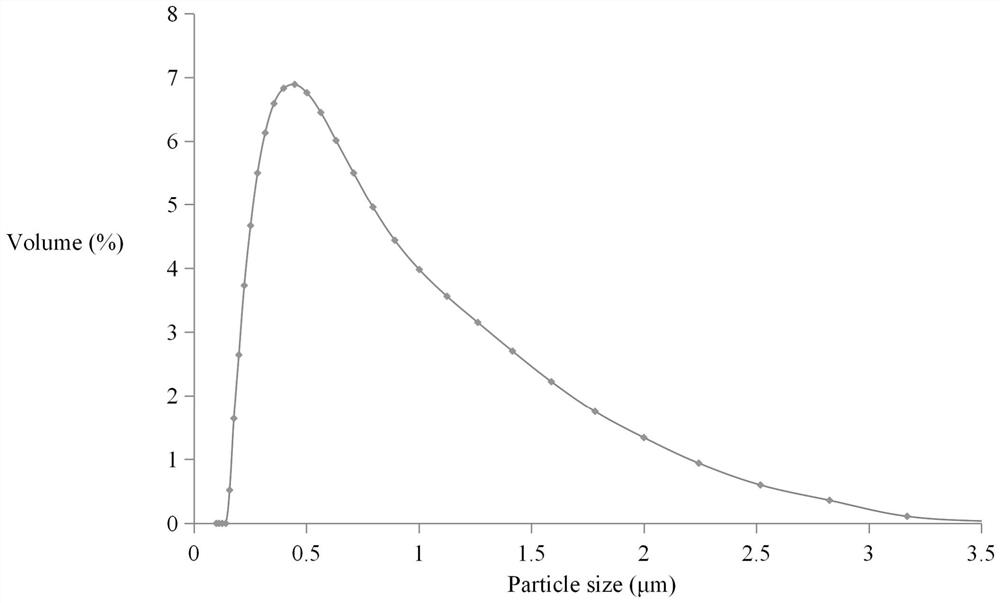

Embodiment 2

[0055] Natural beverage emulsifier B, all calculated by weight percentage, the material is equipped as follows:

[0056] Emulsified water phase raw materials: 15.2wt% gum arabic, 0.6wt% soap bark extract, 0.2wt% xanthan gum, 1wt% phospholipid, 0.6wt% citric acid, 0.4wt% malic acid, 2wt% lactic acid;

[0057] Emulsified oil phase raw materials: rapeseed oil 16wt%, vitamin E 0.2wt%;

[0058] Ethanol 5wt%, balance is distilled water.

[0059] The preparation method is as follows:

[0060] Step (1): fully dissolve gum arabic and xanthan gum in water in proportion, then add soap bark extract, phospholipids, citric acid, malic acid, and lactic acid and mix them, let stand until the hydration is complete, pass 1 -Three times of disk separation, after each disk separation, take samples and put them into centrifuge tubes for 8 minutes at a centrifuge speed of 4000rpm, observe the impurities at the bottom of the centrifuge tubes, it is advisable that there is no insoluble matter; Aft...

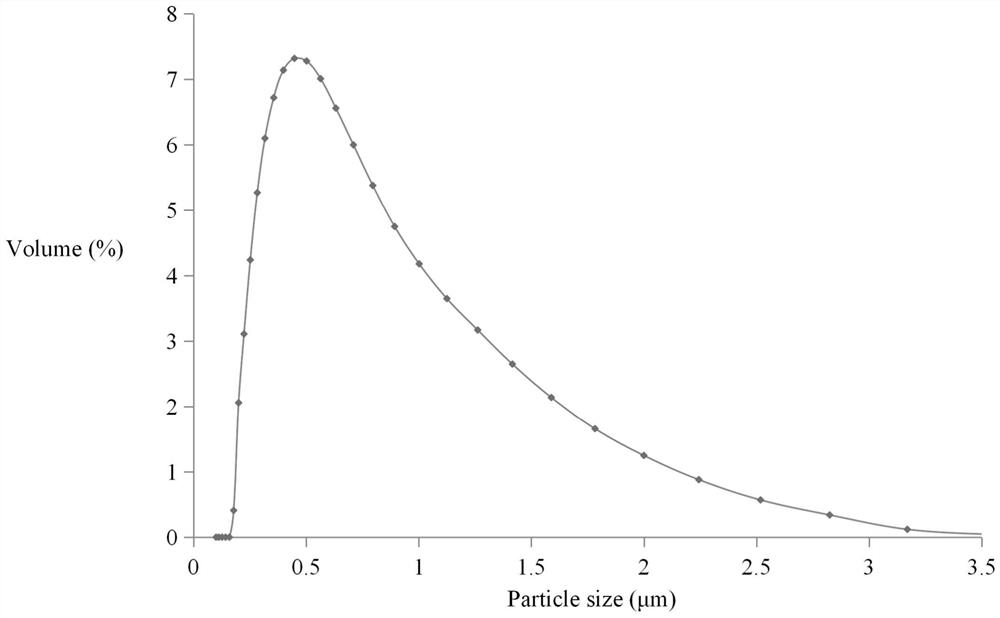

Embodiment 3

[0066] Natural beverage emulsifier C, all calculated by weight percentage, the materials are equipped as follows:

[0067] Emulsified water phase raw materials: 18wt% gum arabic, 0.2wt% soap bark extract, 0.1wt% xanthan gum, 0.7wt% phospholipid, 0.4wt% citric acid, 0.1wt% malic acid, 2.5wt% lactic acid;

[0068] Emulsified oil phase raw materials: soybean oil 18wt%, rosemary extract 0.02wt%;

[0069] Ethanol 4wt%, balance is distilled water.

[0070] The preparation method is as follows:

[0071] Step (1): fully dissolve gum arabic and xanthan gum in water in proportion, then add soap bark extract, phospholipids, citric acid, malic acid, and lactic acid and mix them, let stand until the hydration is complete, pass 1 -Three times of disk separation, after each disk separation, take samples and put them into centrifuge tubes for 8 minutes at a centrifuge speed of 3000rpm, observe the impurities at the bottom of the centrifuge tubes, it is advisable that there is no insoluble m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com