High-gain forward-flyback laminated boost converter

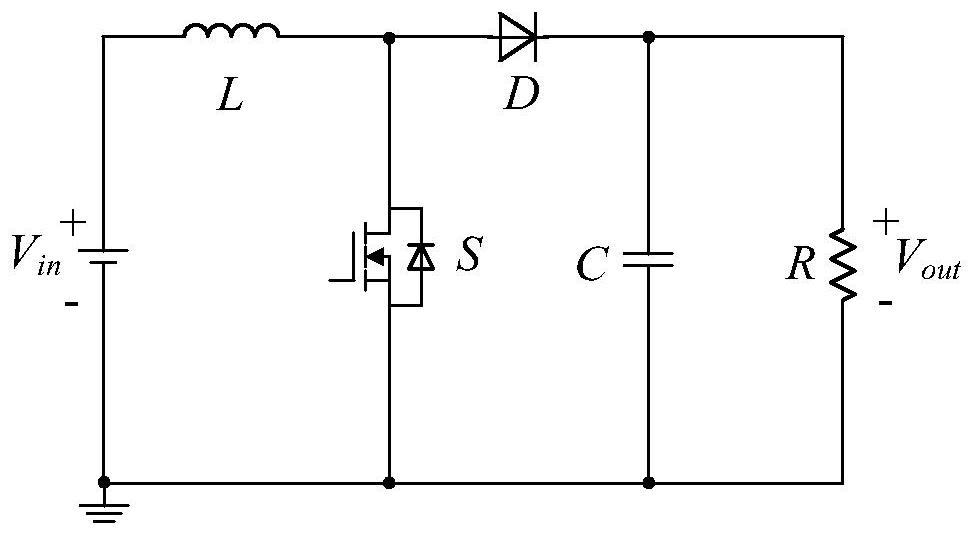

A boost converter, forward and flyback technology, used in high-efficiency power electronic conversion, conversion of DC power input to DC power output, instruments, etc., can solve the input current discontinuity, increase the volume of the output capacitor, and increase the conduction loss. and other problems to achieve the effect of optimizing input current, continuous input current and reducing ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Contraction below Figure 5 ~ 6 The present invention will be further described in further detail.

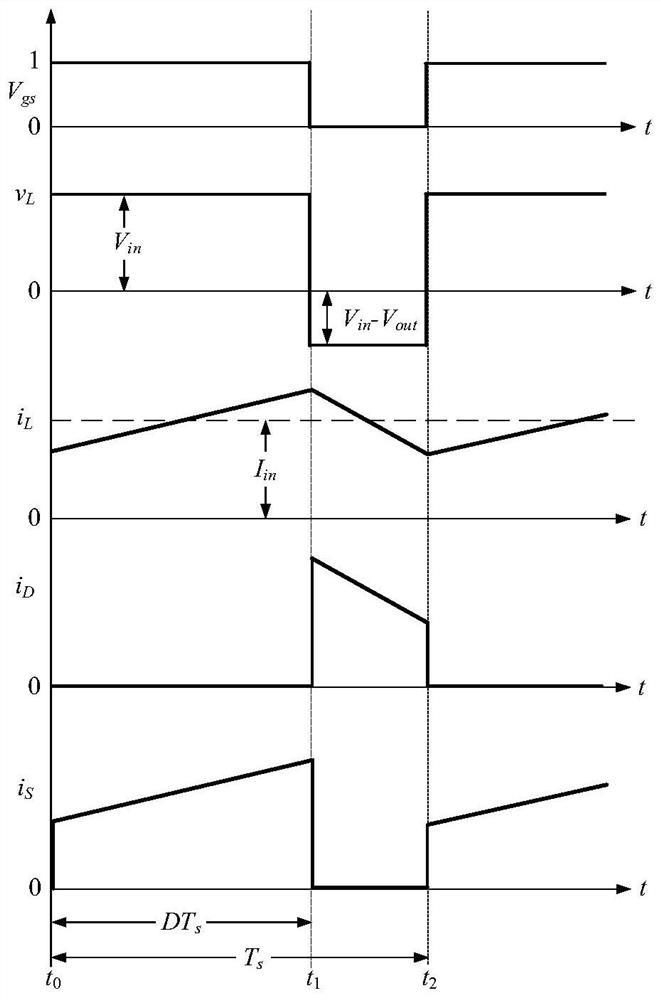

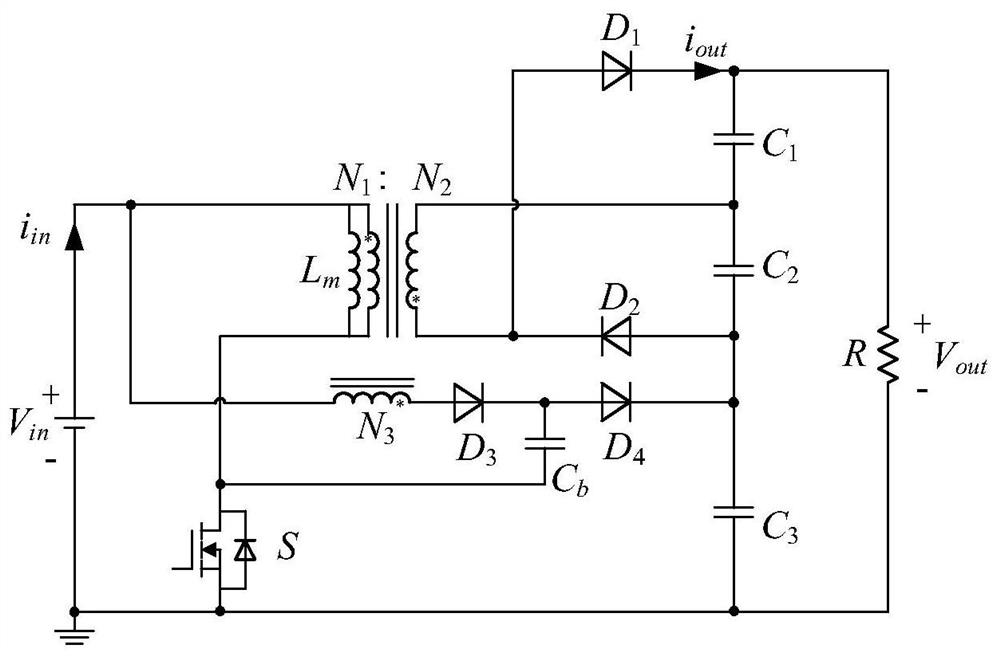

[0056] The present invention proposes a high gain positive antitock layer boost converter, a circuit diagram of a converter such as Figure 5 Indicated. The number of turns of the primary winding of the transformer is n 1 , The number of turns of the secondary winding is n 2 , The number of turns of the third winding is n 3 K 1 K 2 For the ratio of transformers, where K 1 = N 2 / N 1 K 2 = N 3 / N 1 . D is the duty cycle of the power switch tube S, the control signal and the main waveform such as Figure 6 Indicated. The converter described in this application has a continuous and high efficiency characteristics in high gain conditions.

[0057] High gain positive anti-stacked layer boost converters use stacks and leak energy ideas. The third windings and diodes are introduced using laminated ideas. To reduce the volume of the converter, the third winding is coupled to the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com