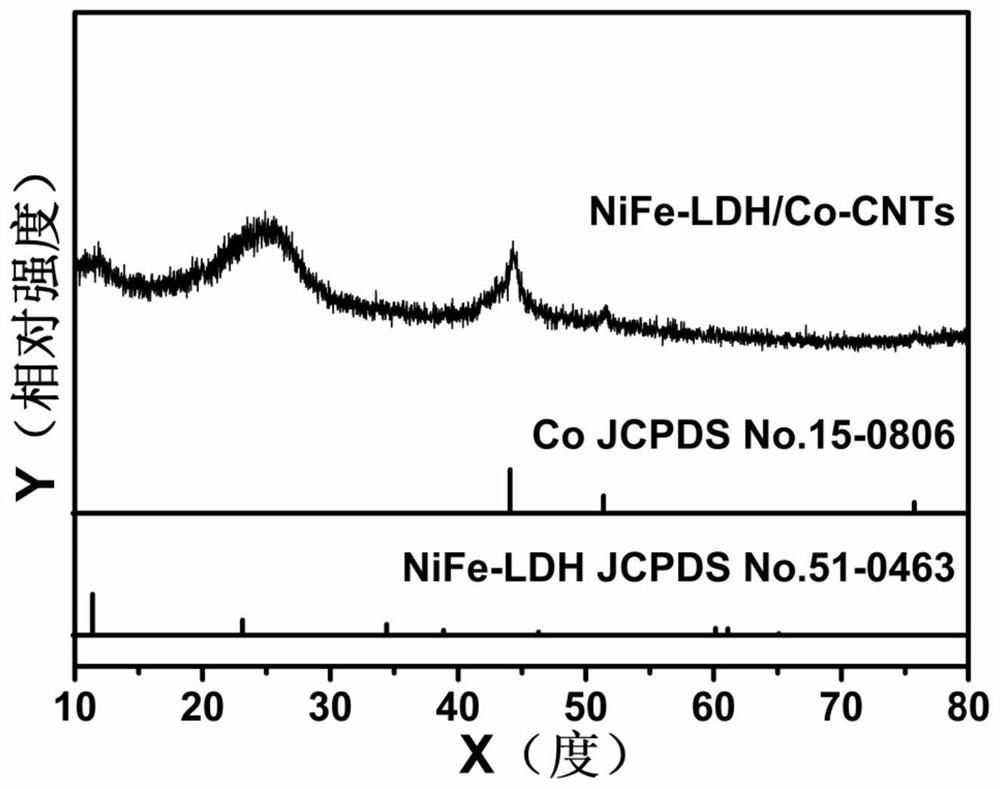

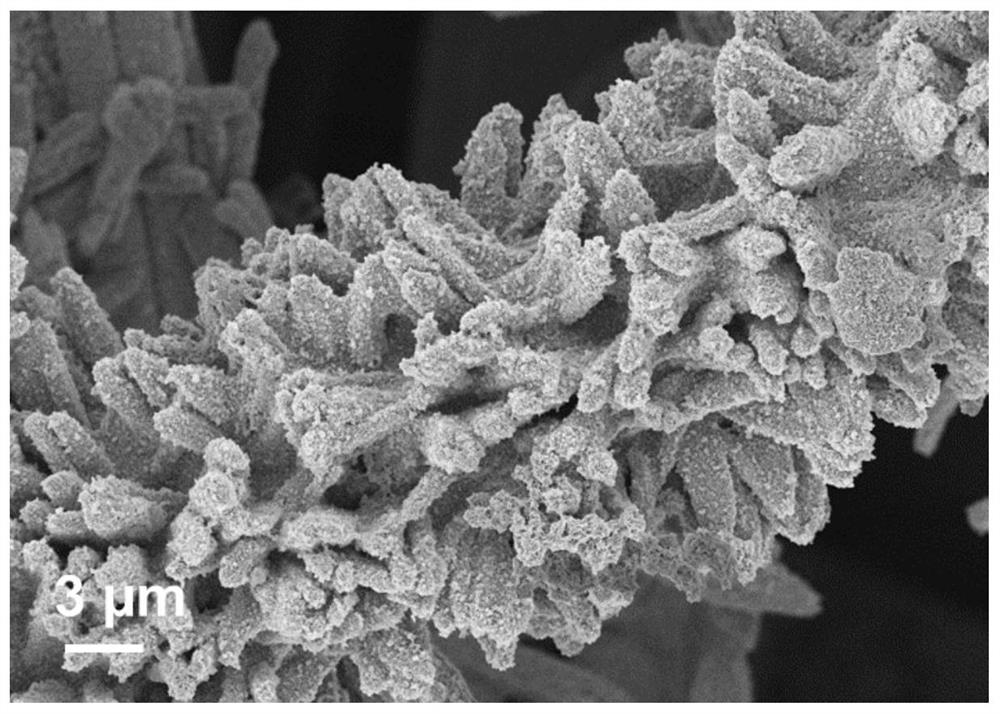

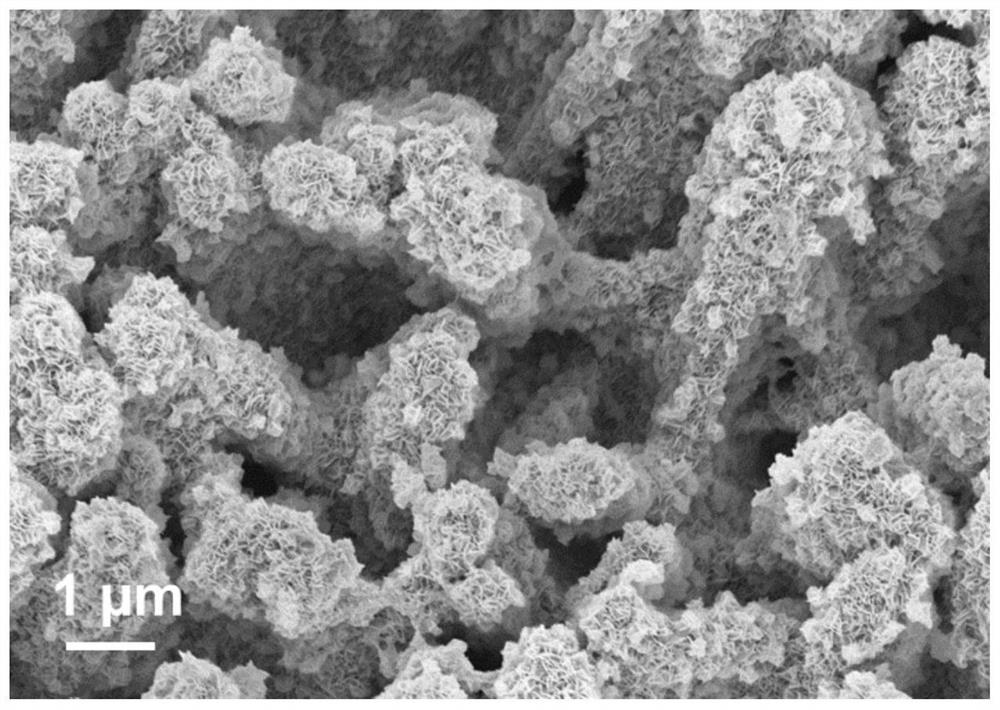

A kind of nife-ldh/co-cnts nanocomposite material and its preparation method and application

A nanocomposite material and nanomaterial technology, applied in the field of NiFe-LDH/Co-CNTs nanocomposite material and its preparation, can solve the problems of insufficient zinc-air battery performance, high bifunctional activity, etc., and achieve high energy conversion efficiency and cycle The effect of stability, high bifunctional activity, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Treatment of carbon cloth (CC)

[0040] The carbon cloth was immersed in acetone solution and ultrasonically treated for 15 minutes. After ultrasonication, it was washed several times with absolute ethanol and deionized water, and then the carbon cloth was immersed in concentrated nitric acid (HNO). 3 ), stirred in a water bath at 60°C for 2 hours, and finally washed several times with absolute ethanol and deionized water, and set aside.

[0041] (2) Preparation of Co-ZIF / CC

[0042] 0.582g of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) was dissolved in 40 mL of deionized water, poured into 40 mL of deionized water in which 1.32 g of 2-methylimidazole (2-MIM) was dissolved, and after ultrasonically mixed at room temperature, the treated carbon cloth (CC) It was added to the formed purple solution and aged for 4 hours after complete immersion. The carbon cloth on which Co-ZIF was grown was taken out, rinsed with deionized water several times, and dried at 80 °C for 6 ho...

Embodiment 2

[0056] (1) Treatment of carbon cloth (CC)

[0057] The carbon cloth was immersed in acetone solution and ultrasonically treated for 15 minutes. After ultrasonication, it was washed several times with absolute ethanol and deionized water, and then the carbon cloth was immersed in concentrated nitric acid (HNO). 3 ), stirred in a water bath at 60°C for 2 hours, and finally washed several times with absolute ethanol and deionized water, and set aside.

[0058] (2) Preparation of Co-ZIF / CC

[0059] 0.582g of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) was dissolved in 40 mL of deionized water, poured into 40 mL of deionized water in which 1.32 g of 2-methylimidazole (2-MIM) was dissolved, and after ultrasonically mixed at room temperature, the treated carbon cloth (CC) It was added to the formed purple solution and aged for 4 hours after complete immersion. The carbon cloth on which Co-ZIF was grown was taken out, rinsed with deionized water several times, and dried at 80 °C for 6 ho...

Embodiment 3

[0065] (1) Treatment of carbon cloth (CC)

[0066] The carbon cloth was immersed in acetone solution and ultrasonically treated for 15 minutes. After ultrasonication, it was washed several times with absolute ethanol and deionized water, and then the carbon cloth was immersed in concentrated nitric acid (HNO). 3 ), stirred in a water bath at 60°C for 2 hours, and finally washed several times with absolute ethanol and deionized water, and set aside.

[0067] (2) Preparation of Co-ZIF / CC

[0068] 0.582g of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) was dissolved in 40 mL of deionized water, poured into 40 mL of deionized water in which 1.32 g of 2-methylimidazole (2-MIM) was dissolved, and after ultrasonically mixed at room temperature, the treated carbon cloth (CC) It was added to the formed purple solution and aged for 4 hours after complete immersion. The carbon cloth on which Co-ZIF was grown was taken out, rinsed with deionized water several times, and dried at 80 °C for 6 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com