Preparation method and application of metallic nickel-based nano material

A nanomaterial, nickel-based technology, applied in the analysis of materials, electrochemical variables of materials, material analysis by electromagnetic means, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

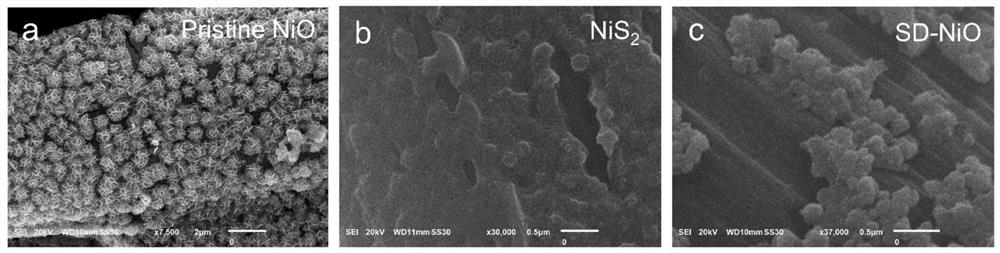

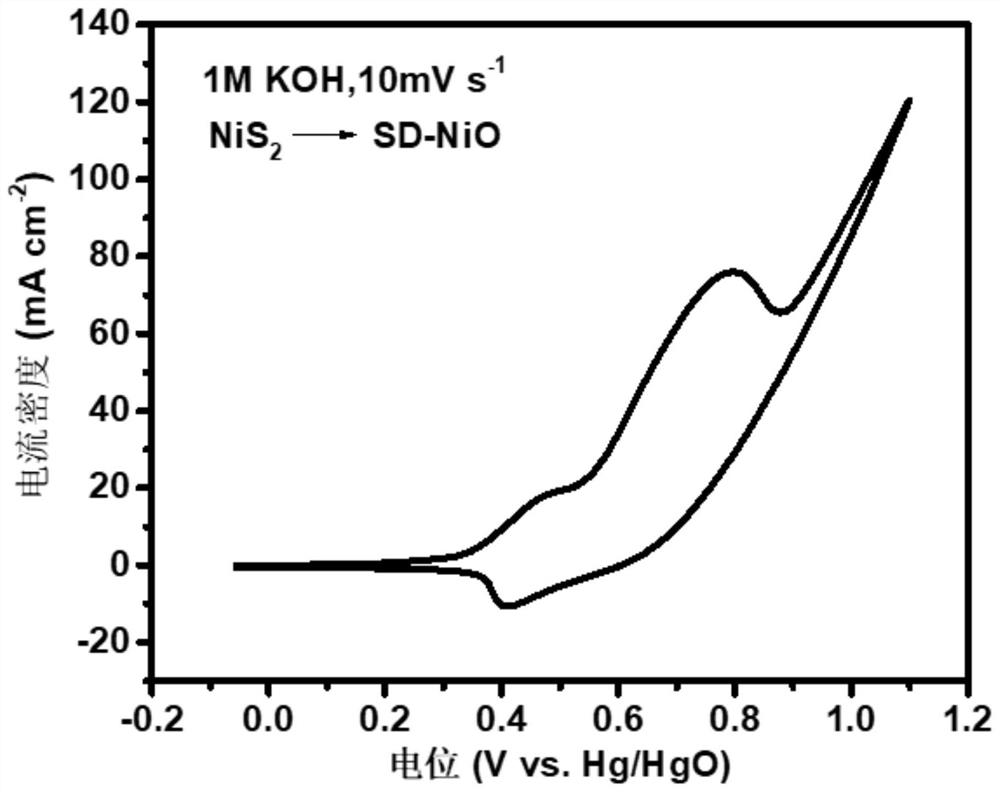

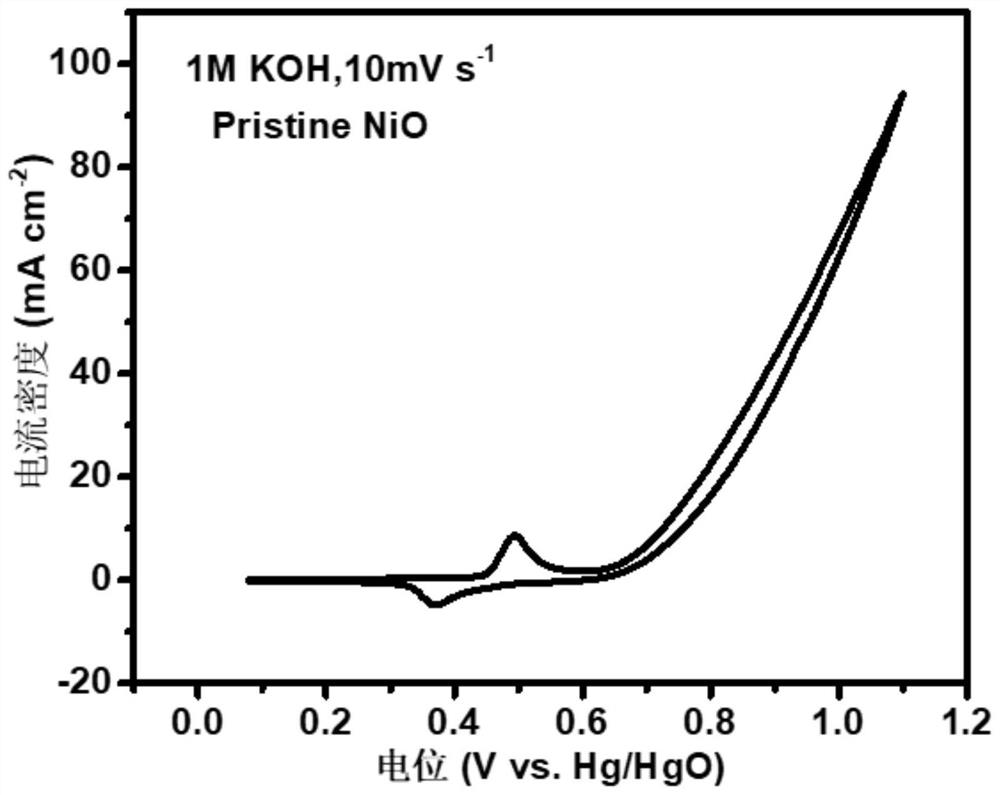

[0033] A preparation method of metal nickel-based nanomaterial (SD-NiO), comprising the following steps:

[0034] Step 1: NiO is electrodeposited on conductive substrate carbon paper (CP): the carbon paper washed with ethanol and deionized water is used as the working electrode, Pt is used as the counter electrode, and saturated calomel electrode (SCE) is used as the reference electrode, and 100mM Concentration of nickel sulfate hexahydrate (NiSO 4 ·6H 2 O) Ni for electrodeposition 2+ Solution, a constant potential of -1V was applied for 180s at room temperature to conduct NiO electrodeposition, and the nickel oxide supported on the obtained carbon paper was rinsed with deionized water and air-dried at room temperature.

[0035] Step 2: Sulfurization in a tube furnace to convert NiO to NiS 2 : The NiO-deposited carbon substrate material was placed in the center of a tube furnace, the sulfur powder was placed upstream of the furnace, and the inert atmosphere N 2 In the pr...

Embodiment 2

[0039] A preparation method of metal nickel-based nanomaterial (SD-NiO), comprising the following steps:

[0040] Step 1: NiO is electrodeposited on conductive substrate carbon paper (CP): the carbon paper cleaned by ethanol and deionized water is used as the working electrode, Pt is used as the counter electrode, and saturated calomel electrode (SCE) is used as the reference electrode. Prepare 150mM Concentration of nickel sulfate hexahydrate (NiSO 4 ·6H 2 O) Ni for electrodeposition 2+ solution, a constant potential of -1V was applied at room temperature for 90s to conduct NiO electrodeposition, and the nickel oxide supported on the obtained carbon paper was rinsed in deionized water and air-dried at room temperature.

[0041] Step 2: Sulfurization in a tube furnace to convert NiO to NiS 2 : The NiO-deposited carbon substrate material was placed in the center of a tube furnace, the sulfur powder was placed upstream of the furnace, and the inert atmosphere N 2 In the pr...

Embodiment 3

[0054] A preparation method of metal nickel-based nanomaterial (SD-NiO), comprising the following steps:

[0055] Step 1: NiO is electrodeposited on conductive substrate carbon paper (CP): the carbon paper cleaned by ethanol and deionized water is used as the working electrode, Pt is used as the counter electrode, and saturated calomel electrode (SCE) is used as the reference electrode, and a 200mM Concentration of nickel sulfate hexahydrate (NiSO 4 ·6H 2 O) Ni for electrodeposition 2+ Solution, a constant potential of -1V was applied for 60s at room temperature to conduct NiO electrodeposition, and the nickel oxide supported on the obtained carbon paper was rinsed with deionized water and air-dried at room temperature.

[0056] Step 2: Sulfurization in a tube furnace to convert NiO to NiS 2 : The NiO-deposited carbon substrate material was placed in the center of a tube furnace, the sulfur powder was placed upstream of the furnace, and the inert atmosphere N 2 In the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com