A prefabricated beam modeling system and method based on bim technology

A prefabricated beam, prefabricated technology, applied in transmission systems, measuring devices, instruments, etc., can solve the problems affecting the efficiency and quality of design and construction, poor system expansion and use flexibility, and poor modeling data accuracy. Network and system modulation and maintenance are convenient, reducing labor and equipment operating costs, and improving work efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the implementation of the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further elaborated below in conjunction with specific embodiments.

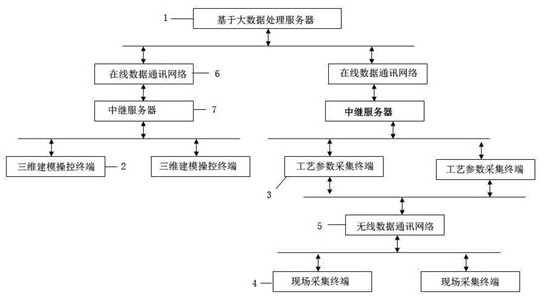

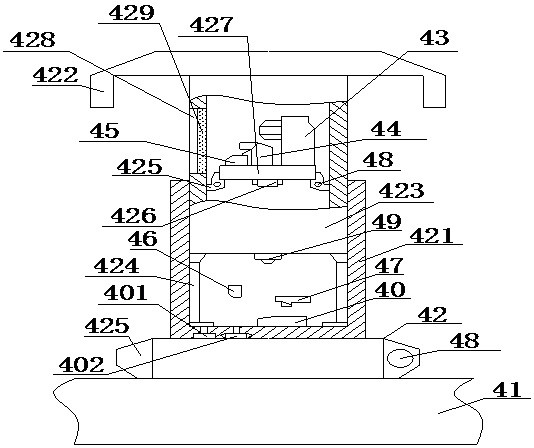

[0023] see figure 1 , a prefabricated prefabricated beam modeling system based on BIM technology, including a big data processing server 1, a three-dimensional modeling control terminal 2, a process parameter acquisition terminal 3, an on-site acquisition terminal 4, a wireless data communication network 5 and an online data communication network 6 , wherein the big data processing server 1 is connected to a number of three-dimensional modeling control terminals 2 and process parameter collection terminals 3 through an online data communication network 6, and constitutes at least one modeling local area network and at least one data collection local area network, and the data collection local area network is additionally connected via wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com