Method for confirming gas content in high-viscosity liquid

A technology with gas content and high viscosity, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as the inability to use pressure detection, and achieve the effects of stable and reliable implementation, cost reduction, and improvement of foaming ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

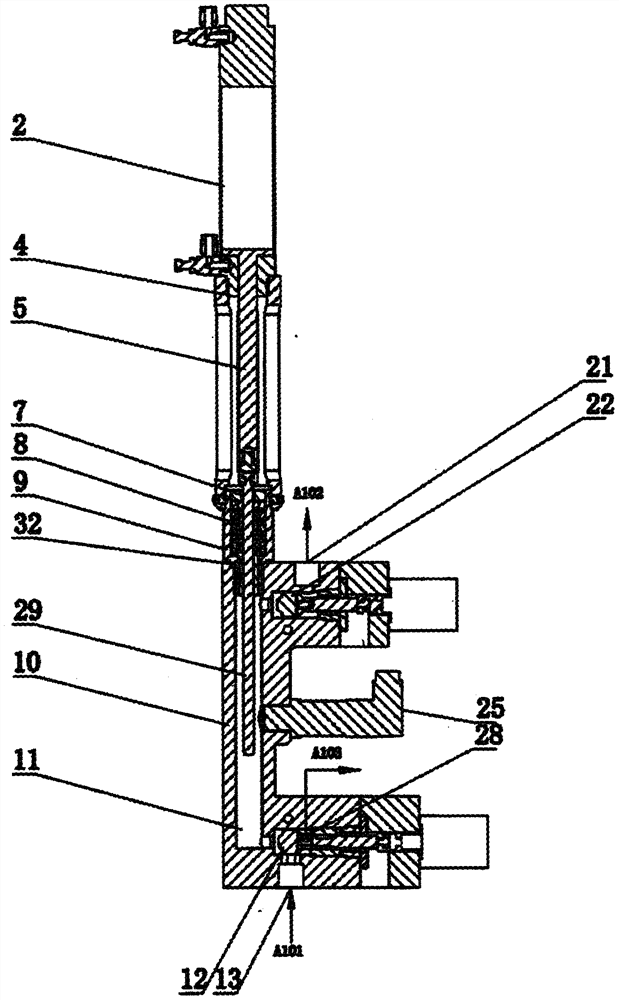

[0026] The present invention discloses a detection device for a gas content in a high viscosity liquid, referred to as a detection device, see figure 1 The gas content used to detect the high viscosity liquid in the welding system is mainly used for dual component or single component high viscosity liquid, such as polyurethane, adhesive, thermal melt glue, in high viscosity liquid or known A high viscosity liquid containing a chemical foaming agent or a physical blowing agent is added to the auxiliary foaming effect, which can obtain a higher foaming magnification product, and the gas does not affect the processing conditions, reduce the cost of the article.

[0027] How to detect the above gas content, there has been no better solution, if there is too much or too little gas, the performance of the product is inevitably affected, how to detect the confirmation gas content, especially the dynamic detection, can obtain better performance products .

[0028] The structure and interc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com