Rock burst resistant supporting method suitable for formed roadway

A rockburst and shock-resistant technology, applied in the field of rockburst-resistant support, can solve problems such as roadway support damage, large deformation, surrounding rock and support unit structure damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

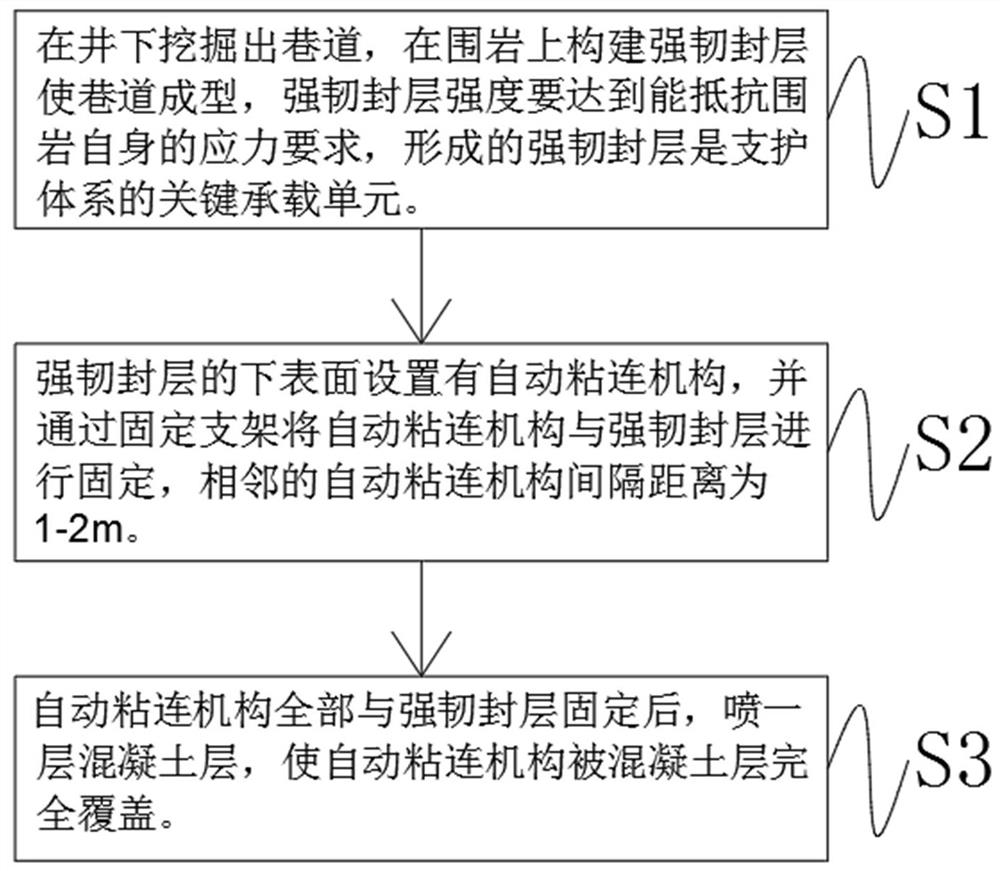

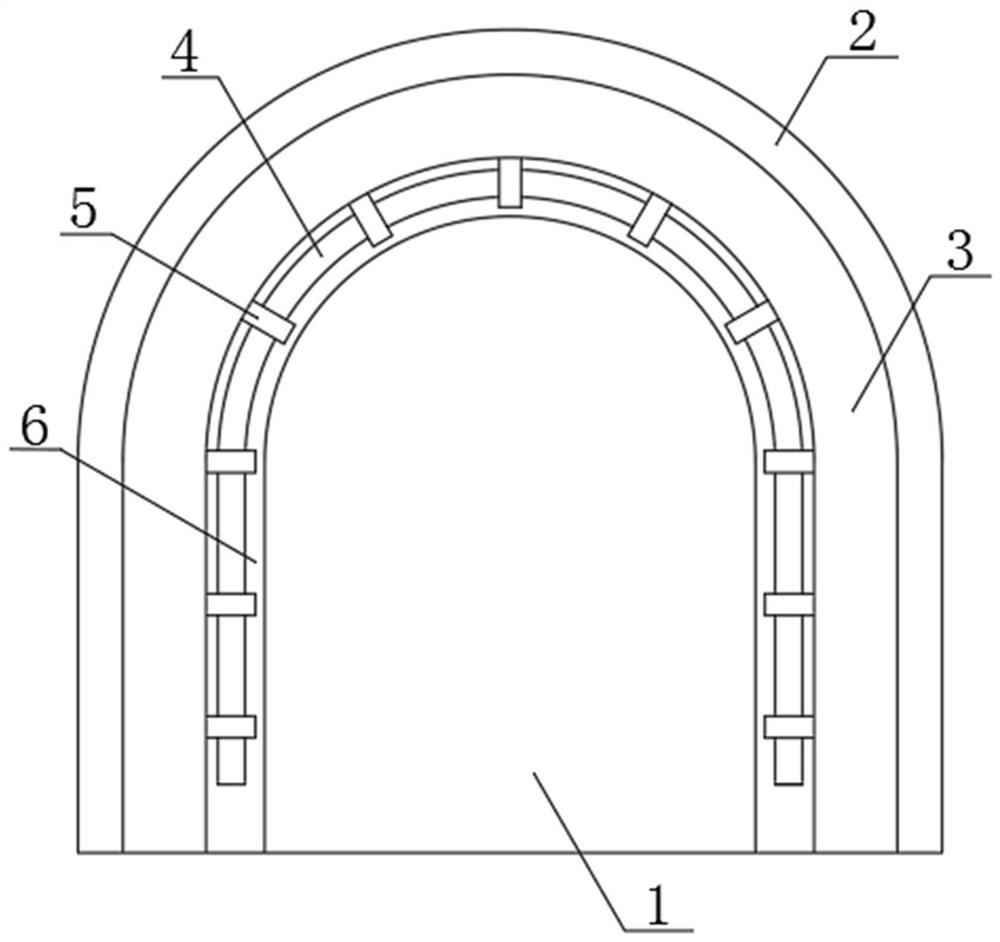

[0031] Such as Figure 1-4 As shown, a support method for anti-shock ground pressure suitable for formed roadways, including the following steps:

[0032] A: Excavate the roadway (1) underground, build a strong seal (3) on the surrounding rock (2) to shape the roadway (1), and the strength of the strong seal (3) must be strong enough to resist the surrounding rock (2) Due to its own stress requirements, the formed strong and tough seal layer (3) is the key bearing unit of the support system;

[0033] B: The lower surface of the strong sealing layer (3) is provided with an automatic adhesion mechanism (4), and the automatic adhesion mechanism (4) is fixed to the strong sealing layer (3) through the fixing bracket (5), and the adjacent automatic The distance between the adhesion mechanism (4) is 1-2m;

[0034] C: After the automatic adhesion mechanism (4) is fully fixed with the tough seal layer (3), spray a layer of concrete layer (6) so that the automatic adhesion mechanism ...

Embodiment 2

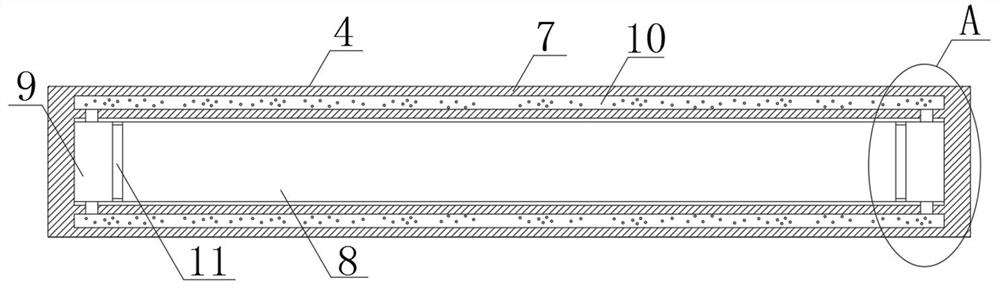

[0042] Such as Figure 2-4 As shown in the figure, a support method suitable for anti-shock ground pressure suitable for forming roadways, including an automatic adhesion mechanism (4) including a pipe body (7), and the inside of the pipe body (7) is provided with a first cavity (8), The second cavity (9) and the third cavity (10), the first cavity (8) and the second cavity (9) are located in the middle of the tube body (7), and the two second cavities (9) are respectively Located at both ends of the first cavity (8), the third cavity (10) is located outside the first cavity (8) and the second cavity (9) to form an annular cavity, the first cavity (8) The interior is filled with a resin agent (15), the interior of the second cavity (9) is filled with a hydrogen peroxide solution (16), and both ends of the first cavity (8) are provided with circular push plates (11). The outer ring of the push plate (11) is provided with a sealing ring (12), the diameter of the sealing ring (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com