Antibacterial antifogging agent, and antibacterial long-acting antifogging wet tissue prepared from same

An anti-fog agent and long-acting technology, which is applied in the direction of chemicals, biocides, disinfectants, etc. for biological control, and can solve problems such as difficulty in forming an anti-fog film layer, failure to achieve anti-fog effect, and uniform spreading of the lens surface , to achieve the effect of improving the anti-fog effect, prolonging the anti-fog time, and reducing the stimulation of human skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

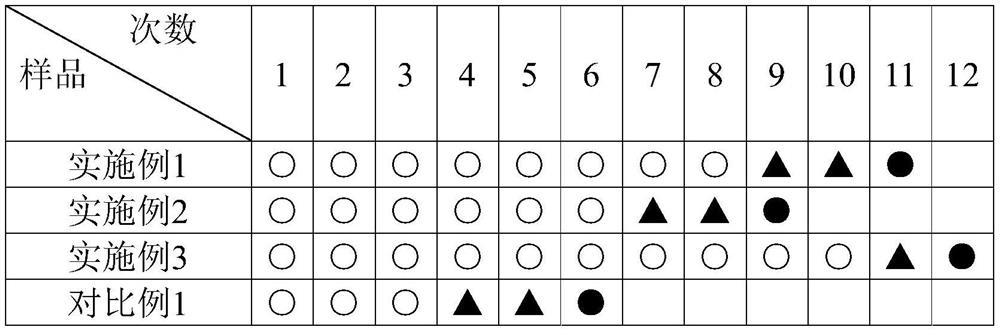

Embodiment 1

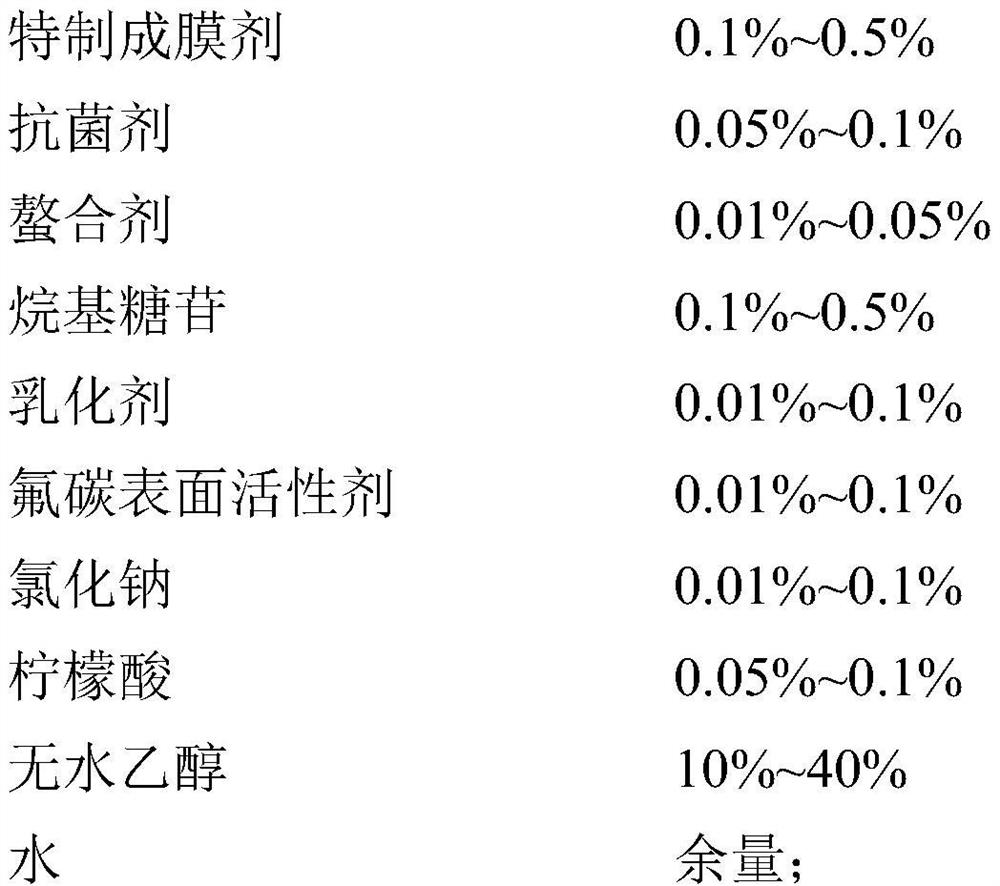

[0029] A kind of preparation method of antibacterial type antifogging agent, described preparation method comprises the steps:

[0030] (1) Mix polyacrylic acid (average molecular weight 3000), hyaluronic acid (average molecular weight 100,000-200,000) and polyethylene glycol 400 in a molar ratio of 1:25:5, heat and stir in a water bath at 80°C for 3 hours, After the reaction, according to the mass ratio of polyacrylic acid 0.5:1, polyvinylpyrrolidone (K29-32) was added to obtain a special film-forming agent;

[0031] (2) Mix 0.1g of special film-forming agent, 0.2g of decyl glucoside, 0.05g of polyhexamethyleneguanidine, 0.07g of AEO-9, 0.01g of disodium edetate and 0.1g of perfluorooctyl Polyoxyethylene ether surfactant, add 20g of water, stir at 80rpm, add 0.01g of sodium chloride and 0.1g of citric acid during stirring, and continue stirring for 0.5h;

[0032] (3) After the stirring is completed, add 20 g of absolute ethanol to the system, add 59.36 g of water, stir and m...

Embodiment 2

[0035] A kind of preparation method of antibacterial type antifogging agent, described preparation method comprises the steps:

[0036] (1) Mix polyacrylic acid (average molecular weight 3000), hydroxypropyl methylcellulose (viscosity 15mPa.s) and polyethylene glycol 400 in a molar ratio of 1:45:5, heat and stir in a water bath at 100°C 1.5h, after the reaction finishes, add carboxymethyl cellulose to obtain a special film-forming agent according to the mass ratio of 0.5:1 to polyacrylic acid;

[0037] (2) Mix 0.3g special film-forming agent, 0.5g decyl glucoside, 0.08g Cathone, 0.1g Tween-20, 0.05g tetrasodium glutamic acid diacetate and 0.01g perfluorooctyl polyoxyethylene ether Surfactants, add 25g of water, stir at 100rpm, add 0.1g of sodium chloride and 0.07g of citric acid during stirring, and continue stirring for 1h;

[0038] (3) After the stirring is completed, add 30 g of absolute ethanol to the system, add 43.79 g of water, stir and mix evenly, and let it stand for...

Embodiment 3

[0041] A kind of preparation method of antibacterial type antifogging agent, described preparation method comprises the steps:

[0042] (1) Mix polyacrylic acid (average molecular weight 3000) and 0588 type polyvinyl alcohol in a molar ratio of 1:10, heat and stir in a water bath at 120°C for 0.5h, after the reaction is complete, mix the polyacrylic acid in a mass ratio of 1:1 , adding copolyvidone (copolymer, 7:3) to obtain a special film-forming agent;

[0043] (2) Mix 0.5g special film-forming agent, 0.1g decyl glucoside, 0.1g Cathone, 0.05g Tween-20, 0.01g tetrasodium glutamic acid diacetate and 0.1g perfluorooctyl polyoxyethylene ether Surfactant, add 30g of water, stir at 100rpm, add 0.06g of sodium chloride and 0.05g of citric acid during stirring, and continue stirring for 1.5h;

[0044] (3) After the stirring is completed, add 40 g of absolute ethanol to the system, add 29.03 g of water, stir and mix evenly, and let it stand for 6 hours to obtain a colorless and transp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com