Ultra-hard wear-resistant transparent film material with silicon-doped carbonized polymer dots as building blocks and preparation method thereof

A technology of polymer dots and silicon doping, applied in coatings, nano-carbons, etc., can solve the problems that cannot meet the requirements of optical protective coatings, and it is difficult to withstand repeated friction of steel wool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

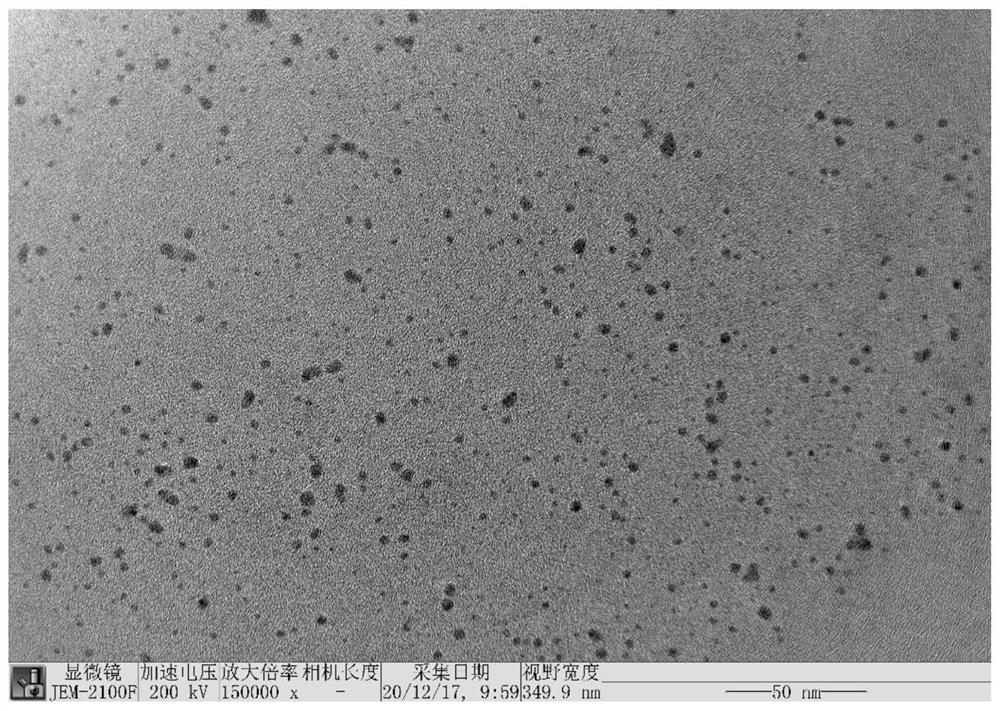

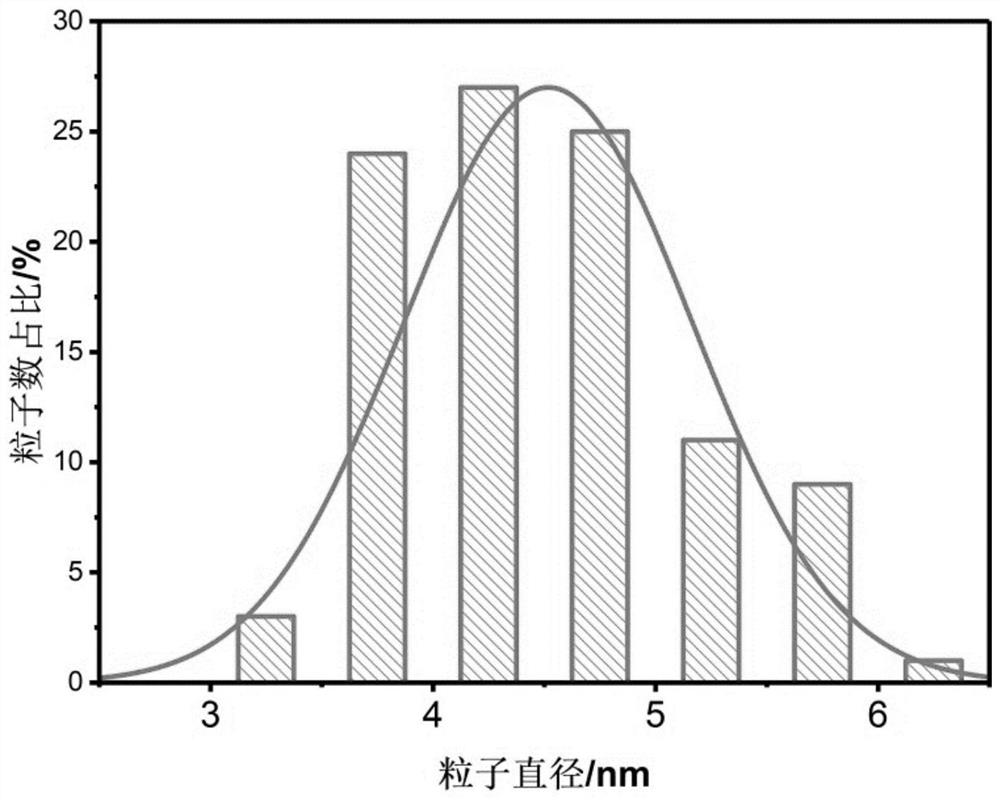

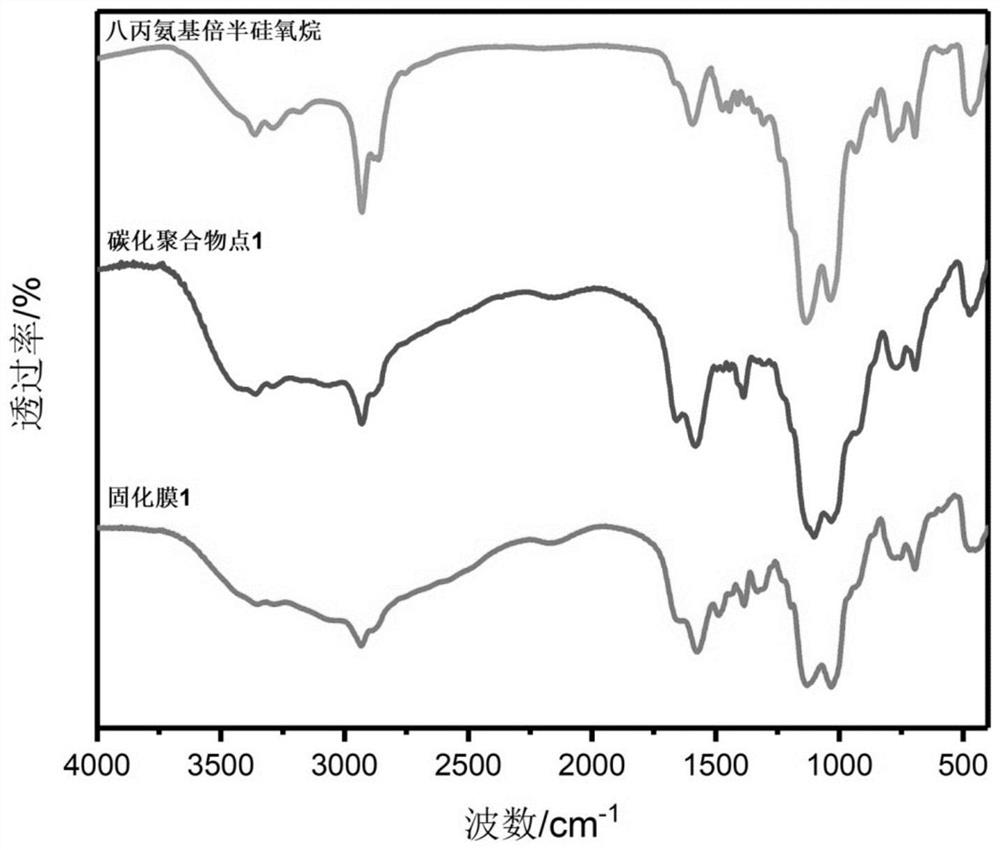

Embodiment 1

[0025] Octapropylaminosilsesquioxane (2.2 g, 2.5 mmol) and citric acid (0.72 g, 3.75 mmol) were weighed, dissolved in 10 mL of deionized water, and stirred until completely dissolved. Transfer the resulting mixed solution to a 25 mL polytetrafluoro-lined reaction kettle, and screw it tightly to make it completely sealed. The reaction kettle was placed in an oven at 180° C., and reacted for 5 hours. Then the reactor was taken out and naturally cooled to room temperature to obtain a pale yellow transparent Si-CPDs aqueous solution. Filter the obtained Si-CPDs aqueous solution with a 0.22 μm polyethersulfone filter membrane to obtain Si-CPDs solidified solution 1, which can be directly coated and solidified, or can be freeze-dried to obtain a dry powder for storage. When ready to use, redissolve in water to cure the coating film.

[0026] Slides were plasma-treated (3 min) to make the surface hydrophilic. Take Si-CPDs curing solution 1, evenly spread it on the surface of the g...

Embodiment 2

[0029] Octapropylaminosilsesquioxane (2.2 g, 2.5 mmol) was weighed. Citric acid (0.48g, 2.5mmol), dissolved in 10mL of deionized water, stirred to dissolve completely. Transfer the resulting mixed solution to a 25 mL polytetrafluoro-lined reaction kettle, and screw it tightly to make it completely sealed. The reaction kettle was placed in an oven at 180° C., and reacted for 5 hours. Then the reactor was taken out and naturally cooled to room temperature to obtain a pale yellow transparent aqueous solution of carbonized polymer dots. Filter the obtained Si-CPDs aqueous solution with a 0.22 μm polyethersulfone filter membrane to obtain Si-CPDs solidified liquid 2; perform the coating film curing according to the operation of Example 1, and obtain the cured film 2, and the performance data are shown in Table 1 .

Embodiment 3

[0031] Octapropylaminosilsesquioxane (2.2 g, 2.5 mmol) was weighed. Citric acid (0.145g, 0.8mmol), dissolved in 10mL of deionized water, stirred to dissolve completely. Transfer the resulting mixed solution to a 25 mL polytetrafluoro-lined reaction kettle, and screw it tightly to make it completely sealed. The reaction kettle was placed in an oven at 180° C., and reacted for 5 hours. Then the reactor was taken out and naturally cooled to room temperature to obtain a pale yellow transparent aqueous solution of carbonized polymer dots. The obtained carbonized polymer dot aqueous solution was filtered with a 0.22 μm polyethersulfone filter membrane to obtain Si-CPDs solidified solution 3; the coating film was solidified according to the operation of Example 1, and the obtained solidified film 3 was obtained. The performance data are shown in the table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com