A system and method for three-dimensional electrocatalytic oxidation of liquid-solid fluidized bed for treating ammonia nitrogen wastewater

An ammonia nitrogen wastewater and catalytic oxidation technology, applied in the fields of chemical industry and environmental protection, can solve the problems of low mass transfer efficiency, heating of the tank, and high electrode cost, and achieve the effects of improving mass transfer efficiency, strengthening water quality circulation, and increasing electrode area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

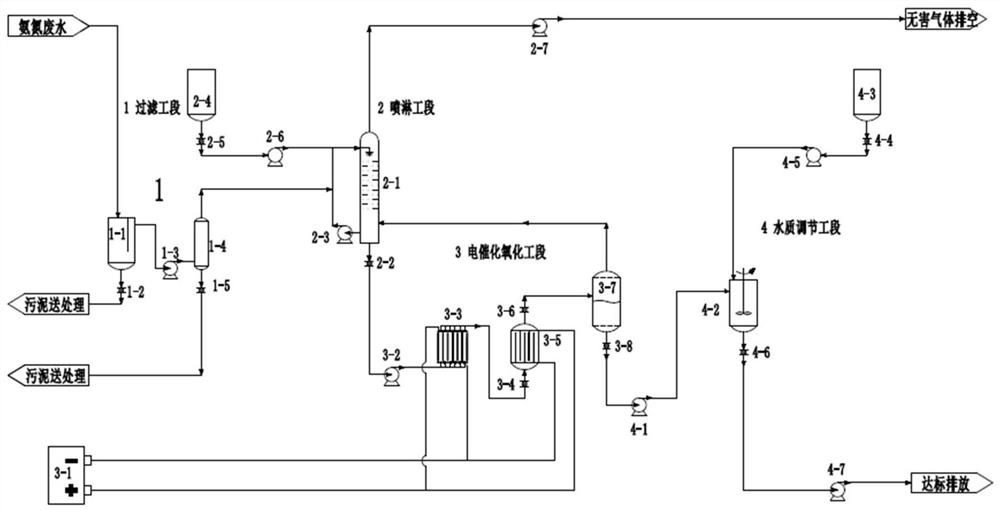

[0066] combine figure 1 , a liquid-solid fluidized bed three-dimensional electrocatalytic oxidation treatment system for ammonia nitrogen wastewater used in this embodiment, the system includes a filtering section 1, a spraying section 2, an electrocatalytic oxidation section 3 and a water quality adjustment section 4;

[0067] Filtration section 1 includes gravity settling tank 1-1, settling tank blowdown valve 1-2, filter inlet pump 1-3, filter 1-4 and filter blowdown valve 1-5;

[0068] The spray section 2 includes spray tower 2-1, spray tower drain valve 2-2, spray pump 2-3, catalyst tank 2-4, catalyst feed valve 2-5, catalyst feed pump 2-6 and Induced fan 2-7;

[0069] The electrocatalytic oxidation section 3 includes a DC power supply 3-1, an electrolytic cell feed pump 3-2, a plate-and-frame electrolytic cell 3-3, a fluidized bed electrolysis liquid inlet valve 3-4, a fluidized bed electrolytic cell 3-5, and a fluidized bed electrolytic cell 3-5. Bed electrolysis liqu...

Embodiment 2

[0077] This embodiment adopts the method for treating ammonia nitrogen wastewater by three-dimensional electrocatalytic oxidation of liquid-solid fluidized bed of the system described in Embodiment 1, which includes the following steps:

[0078] Ammonia nitrogen wastewater is sent to gravity settling tank 1-1, and after gravity settling, supernatant liquid and sludge are obtained; sludge is discharged through settling tank sewage valve 1-2 for treatment; supernatant liquid is sent to filter inlet pump 1-3 In the filter 1-4, the filtered clear liquid and the filtered sludge are obtained; the filtered sludge is discharged through the filter blowdown valve 1-5 for processing; the filtered clear liquid is sent to the spray tower 2-1; The catalyst is sequentially sent to the spray tower 2-1 through the catalyst feed valve 2-5 and the catalyst feed pump 2-6; the electrolytic gas generated by the electrocatalytic oxidation section 3 enters the spray tower 2-1 under the action of negat...

Embodiment 3

[0081] This example takes the printing and dyeing wastewater of a certain enterprise as the treatment object, and the treatment volume is 15m 3 / h, the initial value of ammonia nitrogen is 10000. In the spraying section 2, the catalyst is sodium chloride solution, and the catalyst addition amount is 2% of the quality of ammonia nitrogen wastewater. The plate-and-frame electrolytic cell 3-3 has a built-in porous diaphragm, graphite felts are arranged on both sides of the diaphragm, the water flow is in a parallel structure, and the current is in a series structure. In the plate-frame electrolytic cell 3-3, the anode adopts platinum ruthenium iridium tantalum tin antimony manganese coated titanium electrode; the cathode adopts titanium electrode; the distance between cathode and anode is 2mm; the anode current density is 800A / m 2 . The built-in electrode in the plate-frame electrolytic cell 3-3 adopts an integrated bipolar plate structure, and the coated titanium electrode ado...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com