Industrial wastewater comprehensive treatment and operation optimization method

A technology for comprehensive treatment of industrial wastewater, applied in chemical instruments and methods, multi-stage water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of environmental protection risks, affecting the safe operation of units, etc., to reduce environmental risks, Good macro social benefits, stable long-term operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

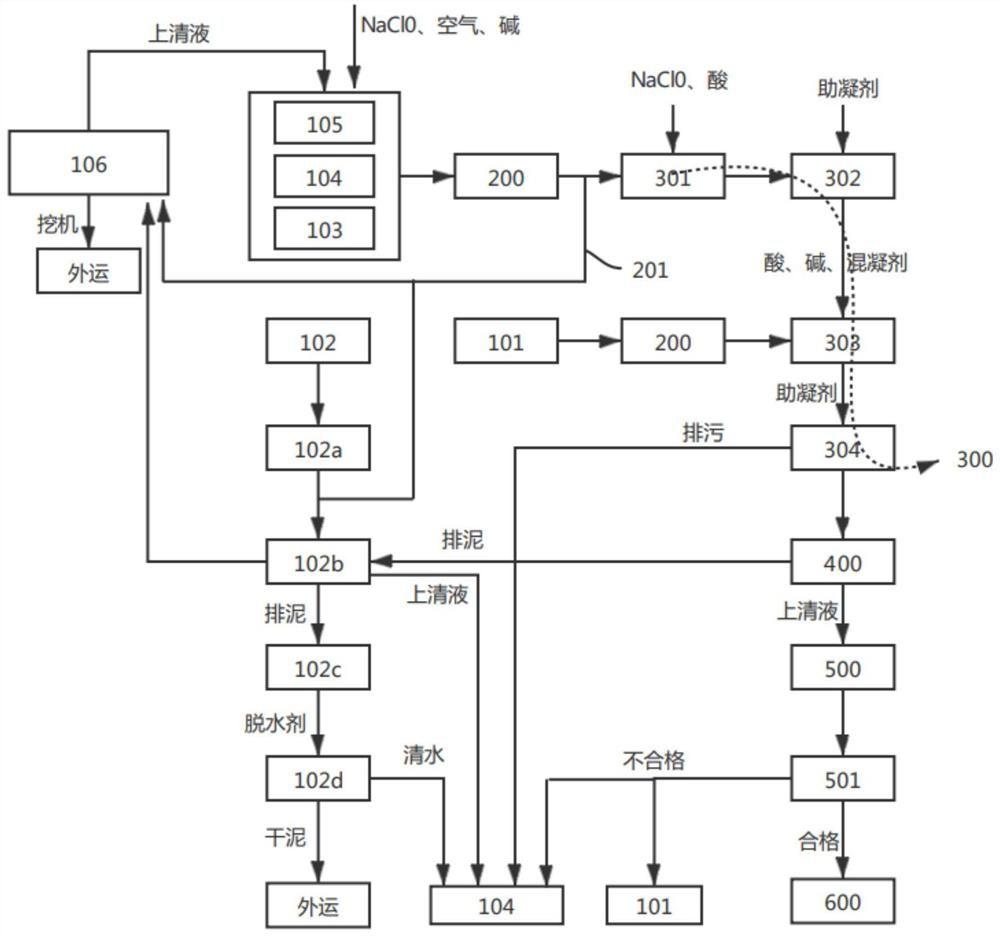

[0029] refer to figure 1 , which is the first embodiment of the present invention, this embodiment provides a method for comprehensive treatment of industrial wastewater and operation optimization, the method for comprehensive treatment of industrial wastewater and operation optimization includes the following steps:

[0030] Various types of wastewater are aerated in the waste liquid tank 100, and sent to the quadruple tank 300 by the wastewater operation pump 200. After the coagulation reaction in the quadruple tank 300, they are quickly precipitated by the inclined tube clarifier 400, and the supernatant is Enter the final neutralization pool 500 and the effluent supervision pool 501;

[0031] The treated industrial wastewater that meets the standards enters the reuse pool 600 for reuse, and the industrial wastewater that fails to meet the standards is discharged from the effluent monitoring pool 501 back to the first waste liquid pool 101 or the fourth waste liquid pool 10...

Embodiment 2

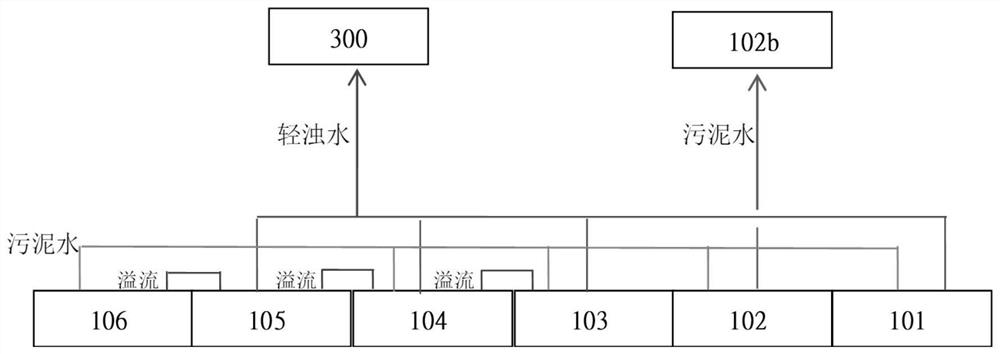

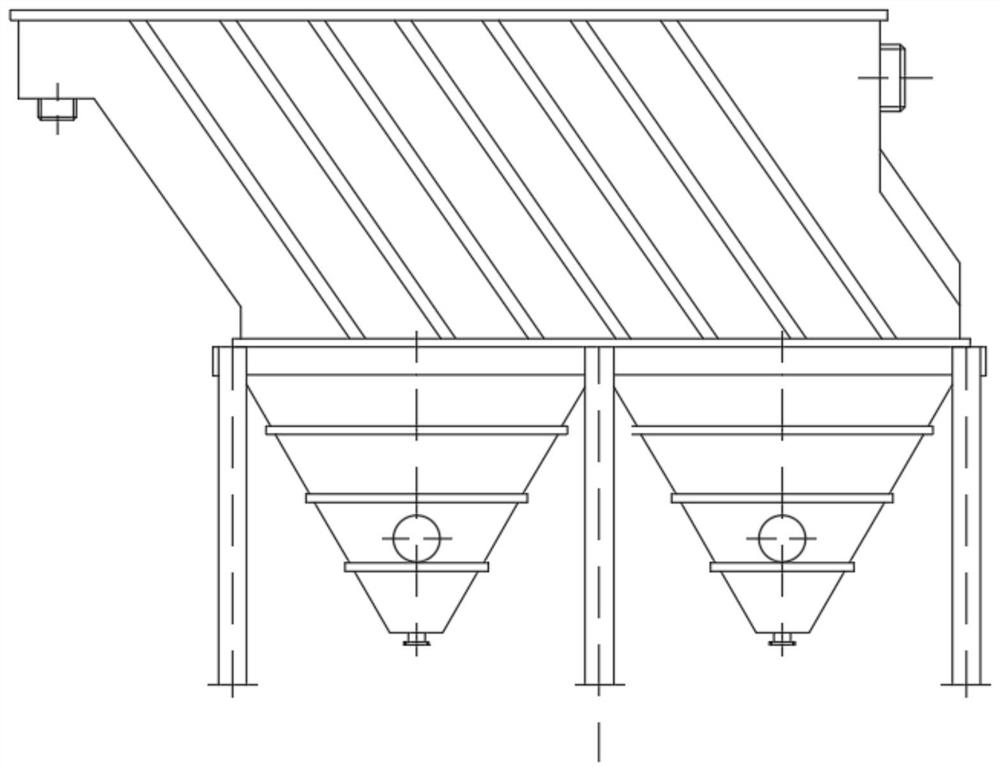

[0039] refer to Figure 1~5 , is the second embodiment of the present invention, which is different from the first embodiment in that: it also includes the waste liquid pool 100 including the first waste liquid pool 101, the third waste liquid pool 103, the fourth waste liquid pool 104 and the first waste liquid pool Five waste liquid pools 105, wherein the first waste liquid pool 101 is an acid-base waste liquid pool, the third waste liquid pool 103, the fourth waste liquid pool 104 and the fifth waste liquid pool 105 are in communication with the desulfurization and polishing pool 106. The desulfurization and slurry pool 106 is close to the fifth waste liquid pool 105, the fourth waste liquid pool 104, and the upper part of the third waste liquid pool 103. An overflow port is dug and a gate is installed on the upper part of the pool wall. After sedimentation and reaching a high liquid level, the supernatant flows to the fifth waste liquid pool 105 , the fourth waste liquid p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com