Device for inserting aluminum core vent plates into casting mold of carbon ceramic brake disc

A technology of inserting a device and a brake disc, which is applied in the directions of ceramic forming cores, ceramic forming mandrels, ceramic forming machines, etc., can solve the problems of labor and other problems, and achieve the effect of improving processing efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

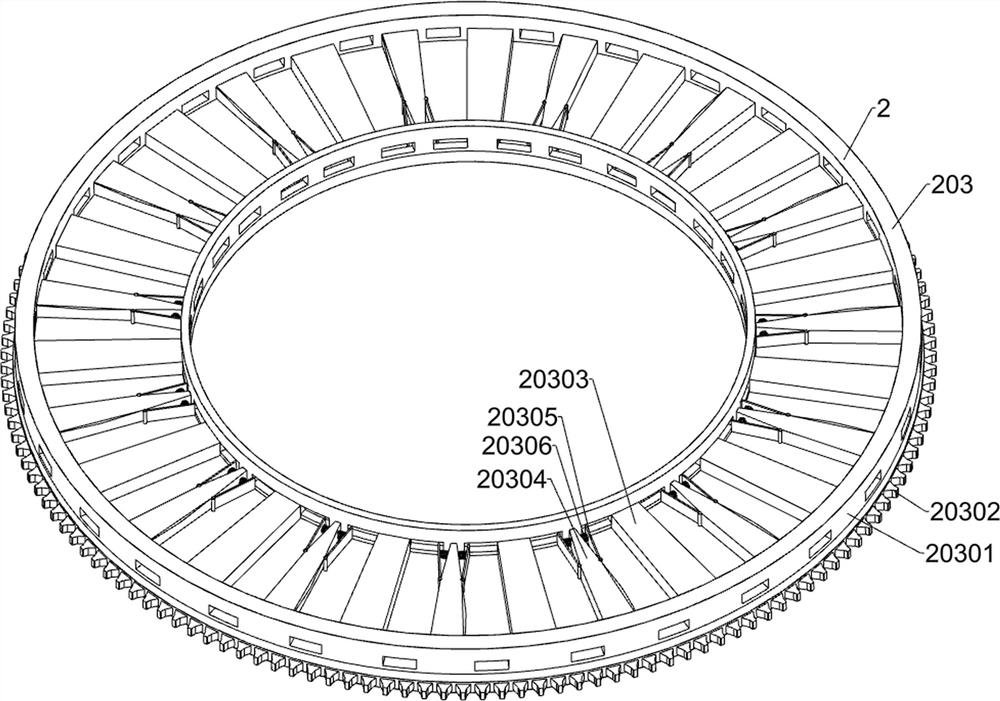

[0034] A carbon ceramic brake disc casting molded aluminum core breather plate insertion device, such as Figure 1-14 As shown, it includes a conveying assembly 1, a plugging assembly 2, a power assembly 3, a support platform 4, a console 5, an aluminum core feeding mechanism 6 and a collection box 7; the conveying assembly 1 is connected with the support platform 4; The solid component 2 is connected with the bracket platform 4; the plug-in component 2 is connected with the power component 3; the plug-in component 2 is connected with the aluminum core feeding mechanism 6; the power component 3 is connected with the bracket platform 4; the console 5 It is connected with the support platform 4; the aluminum core feeding mechanism 6 is connected with the support platform 4; the collection box 7 is connected with the support platform 4.

[0035] Working steps: when in use, first place the device and keep the support platform 4 stable, connect the external power supply, control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com