Scraper type chip removal device and chip removal method

A chip removal device and scraper-type technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of cutting fluid waste, etc., and achieve the effects of reducing carrying capacity, avoiding pollution, and reducing welding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

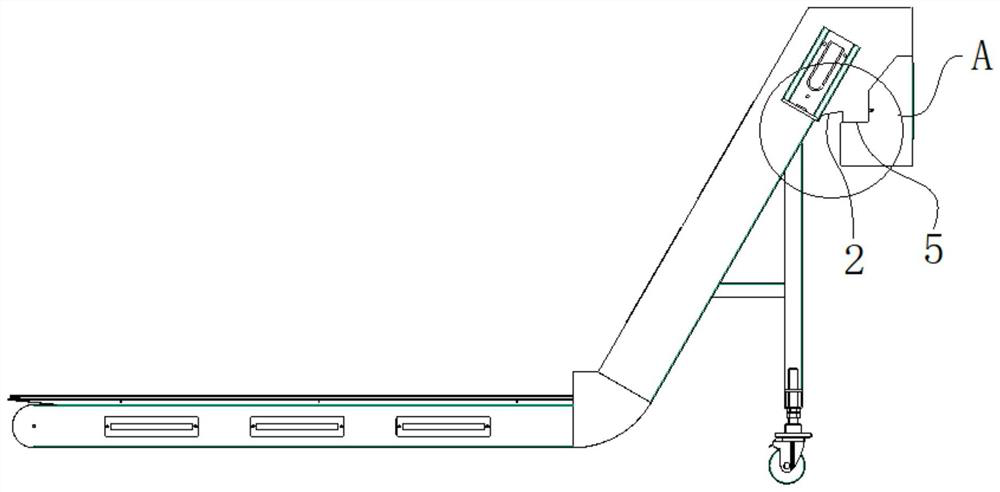

[0032] A scraper type chip removal device of this embodiment, such as figure 2 , 3 As shown, it includes a circulating scraper chain 3 and one end is fixedly connected to the circulating scraper chain 3, and the other end is close to several scrapers 4 of the chip removal climbing section 1; the chip removal climbing section 1 and A chip removal stagnation section 2 is arranged between the chip discharge outlets 5 .

[0033] A scraper type chip removal device in this embodiment makes full use of the adhesion difference between the cutting fluid and the iron filings 6 and the inclination angle of the scraper 4 in the conveying process, and the scraper 4 continuously scrapes the iron scraps 6 to the chip removal The accumulation on the retention section 2, the iron filings 6 accumulated on the chip removal retention section 2 are in the retention process, the cutting fluid breaks away from the iron filings 6 under the action of its own gravity and then flows back into the cutt...

Embodiment 2

[0035] A scraper type chip removal device of this embodiment has the same basic structure as that of Embodiment 1, the differences and improvements are as follows: Figure 1 to Figure 7 As shown, the chip retention section 2 is slope-shaped, and the slope faces inward to allow the cutting fluid to flow inward and avoid outflow.

[0036] The scraper type chip removal device of this embodiment, through the existing such as figure 1 The arc surface section 10 at the top of the chip removal climbing section 1 shown (the purpose is to drop the iron filings in time as much as possible), is improved as figure 2 As shown in the slope surface structure, the upper part of the circulating scraper chain 3 does not need to be extended outward along the arc surface, and a certain height can be reserved directly along the direction of the original chip removal climbing section 1 for circulation. This is simple but ingenious The design has achieved unexpected technical effects: the length o...

Embodiment 3

[0038] A scraper type chip removal device of this embodiment has the same basic structure as that of Embodiment 2, the differences and improvements are as follows: Figure 1 to Figure 7 As shown, the slope angle is 0 to 60°, which is suitable for the separation of iron filings and cutting fluid. If it is too small, it will easily cause excessive accumulation and affect blanking. , and corresponding angle design can be carried out according to different iron filings 6 densities. Generally, the usual iron filings 6 have a slope of 10 to 20° most suitable. A further solution is that the edges on both sides of the chip removal climbing section 1 and the chip removal retention section 2 can be designed to be tilted upwards to form a structure with the warped edges upward, thereby forming a downward flow channel for the cutting fluid to prevent the cutting fluid from flowing along the sides. Spilling can also prevent iron filings from falling along the side.

[0039] The chip remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com