Kitchen waste processor with detection and fault removal functions and control method

A technology of kitchen waste and processor, which is applied in the field of kitchen waste treatment equipment, can solve problems such as complex characteristics, waste of electric energy, easy to forget to stop, etc., and achieve the effect of high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiment of Kitchen Waste Disposer

[0021] The kitchen waste disposer provided in this embodiment includes a housing, a control module, a feeding sensing module, a program mode selection module, a grinding and crushing module, and a torque sensing module. The casing is provided with a cavity and a feeding port, and the feeding port communicates with the cavity. The feeding sensing module, the program mode selection module, the grinding and crushing module and the torque sensing module are respectively connected with the control module.

[0022] The feeding sensing module is arranged in the cavity or in the feeding port, and the feeding sensing module is used to sense whether there is kitchen waste in the cavity and send a standby start instruction to the control module. The feeding sensing module includes at least one of the following: a photoelectric sensor, a temperature sensor, a weighing sensor, a magnetic sensor and a pressure sensor.

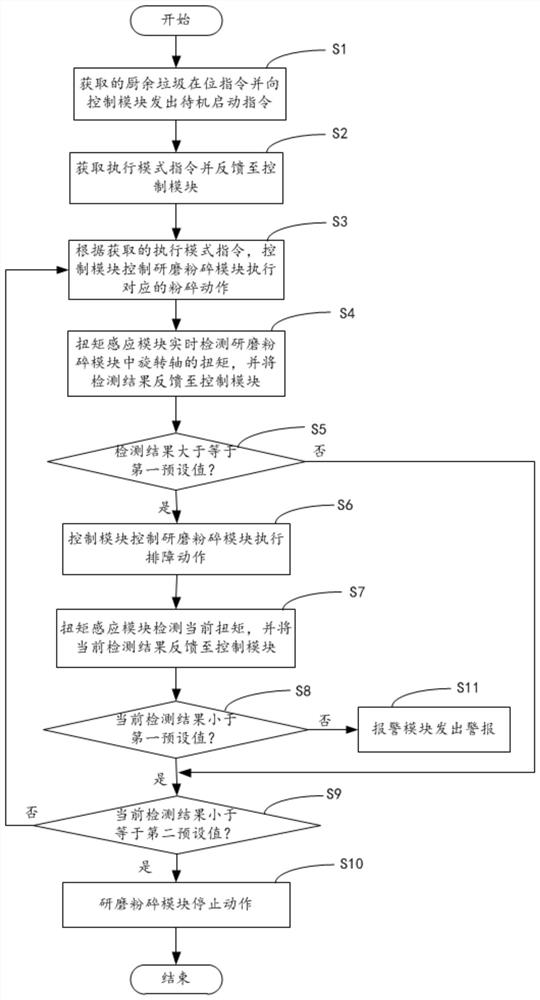

[0023] see figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com