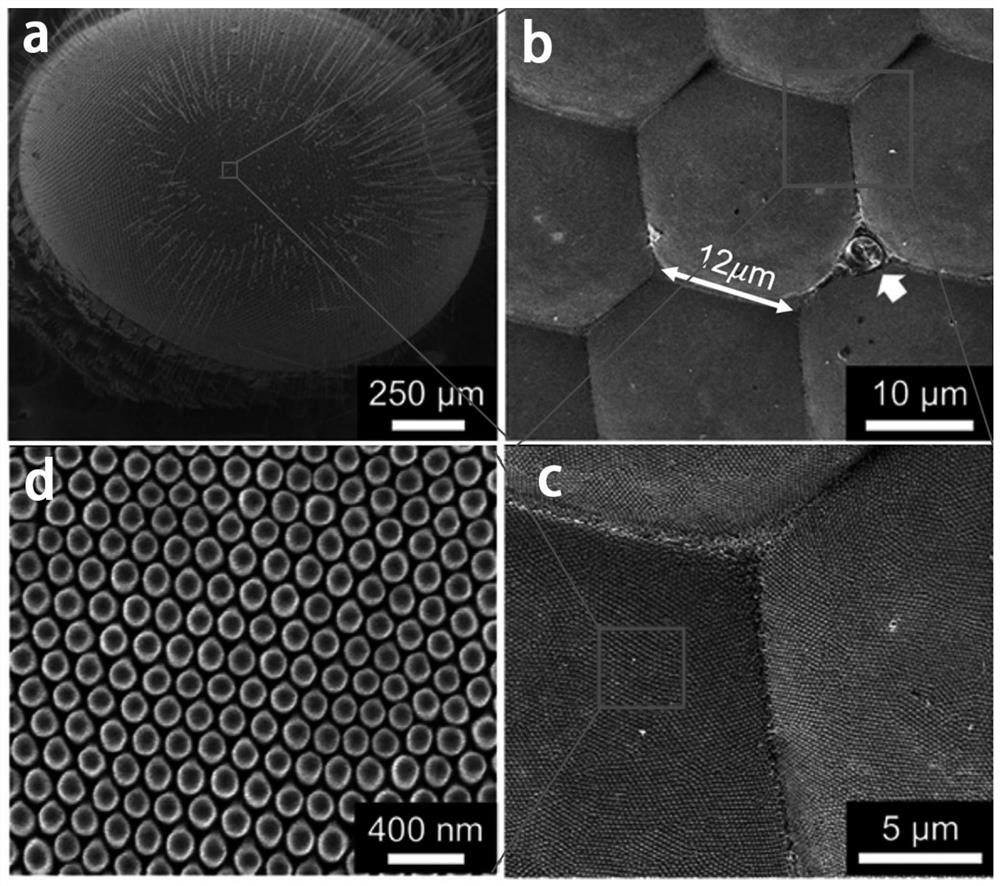

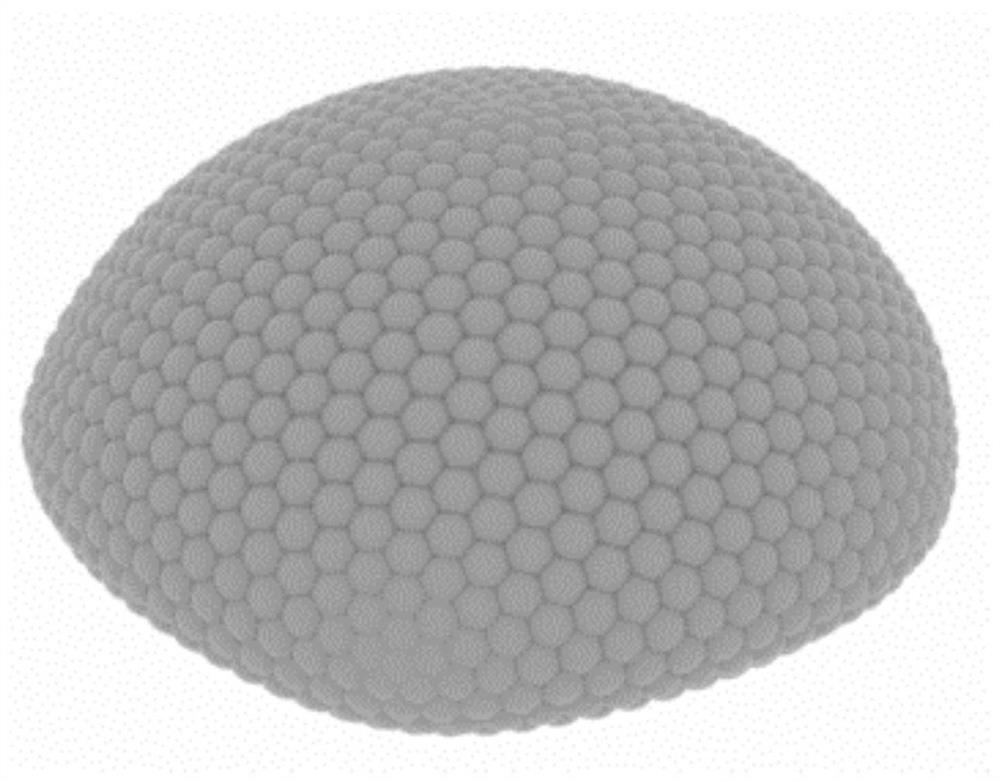

Preparation method of high-transmittance antireflection film with butterfly-compound-eye-imitated inverse opal secondary structure

A technology of inverse opal and secondary structure, which can be applied to devices, instruments, optical components, etc. for coating liquid on the surface, which can solve the problem of high reflectivity of battery panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

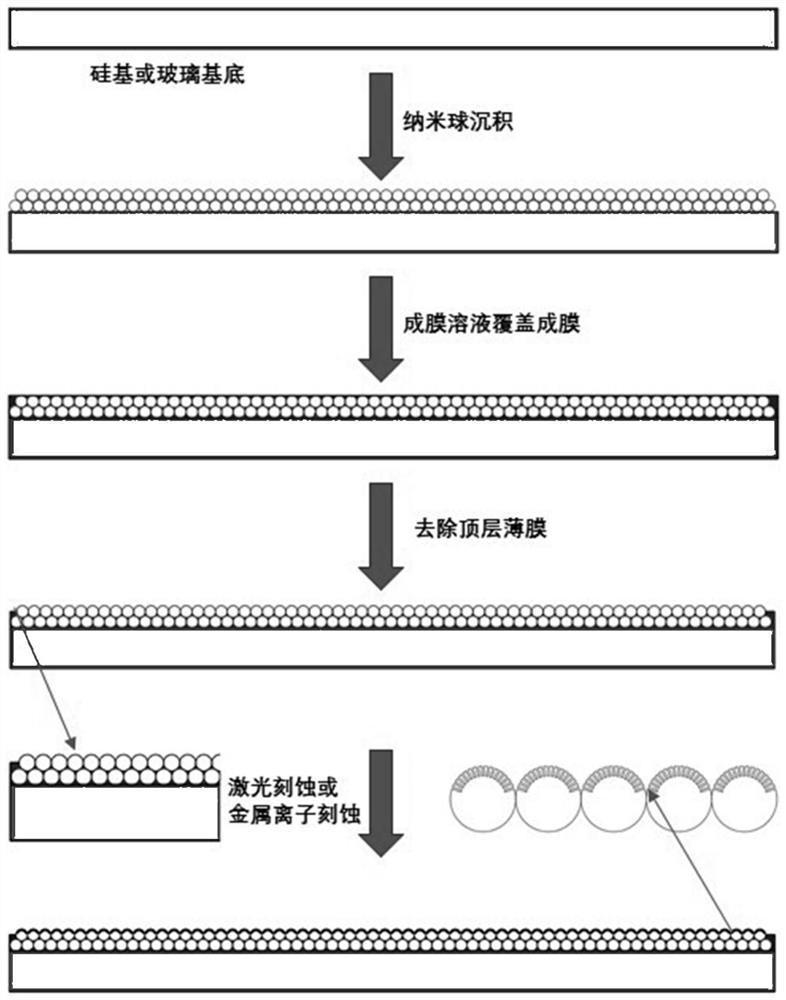

[0039] Such as figure 2 with Figure 5 As shown, a method for preparing a butterfly-like compound eye anti-opal secondary structure high-transparency anti-reflection film of the present invention comprises the following steps:

[0040] Step S100, providing a substrate.

[0041] Specifically, the substrate can be a transparent substrate, and can be any substrate that needs to increase light transmission and reduce reflection. For example, the substrate is a silicon-based substrate or a glass substrate. When a silicon-based substrate is used, it can be applied to silicon-based thin film solar cells, and more More light passes through the film to the solar cell and is converted into electricity. In the embodiment of the present invention, in order to increase the transmittance of the substrate and reduce the reflectance of the substrate, any other substrates that need to increase the transmittance and reduce the reflectance can use the method of the present invention to form m...

specific Embodiment 1

[0085] 1. The microspheres are dissolved in the mixed solution of ethanol and water. The microspheres are silica spheres, and the radius size is between 3-4 microns. The ratio of microspheres, ethanol and water is 0.05:35:5, spin coating Speed 110 rpm, spin coating for 1 minute, acceleration time 10 seconds, deceleration time 10 seconds, place in a ventilated place for 9 minutes, spin coating again after evaporating solvent, repeat 4 times.

[0086] 2. Configure the film-forming solution, and the solution solidifies to form a film. The film-forming solution is epoxy resin. The film-forming solution is epoxy resin solution, the mass ratio of main agent and curing agent is 3:1, the spin coating speed is 800 rpm, spin coating for 1 minute, including acceleration time of 10 seconds, deceleration time of 10 seconds, curing temperature 85°C, curing time 6 hours, curing in blast drying oven.

[0087]3. Prepare the dissolving solution, acetone, ethyl acetate and butyl acetate acco...

specific Embodiment 2

[0090] 1. The microspheres are dissolved in the mixed solution of ethanol and water. The microspheres are polystyrene balls with a radius of 3-4 microns. The ratio of microspheres, ethanol and water = 0.05:36:6, spin coating Speed 120 rpm, spin coating for 1 minute, acceleration time 10 seconds, deceleration time 10 seconds, place in a ventilated place for 10 minutes, spin coating again after evaporating solvent, repeat 5 times.

[0091] 2. Configure the film-forming solution, and the solution solidifies to form a film. The film-forming solution is polydimethylsiloxane, the ratio of main agent and curing agent is 11:1, the spin coating speed is 900 rpm, spin coating for one minute, including acceleration time of 10 seconds, deceleration time of 10 seconds, curing temperature 80°C, curing time 120 minutes, curing in blast drying oven.

[0092] 3. Prepare the dissolving solution, acetone, ethyl acetate and butyl acetate according to the ratio of 6:4:1, spin coating speed 90 r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com