Stirring type flotation machine for tailing redevelopment and utilization

A re-development and stirring-type technology, applied in the field of tailings re-development and utilization of agitated flotation machines, can solve the problems of affecting the use effect, foam accumulation, inconvenience of rapid rise and discharge, etc., to eliminate rotary motion and improve the effect of stirring treatment. , Improve work efficiency and use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

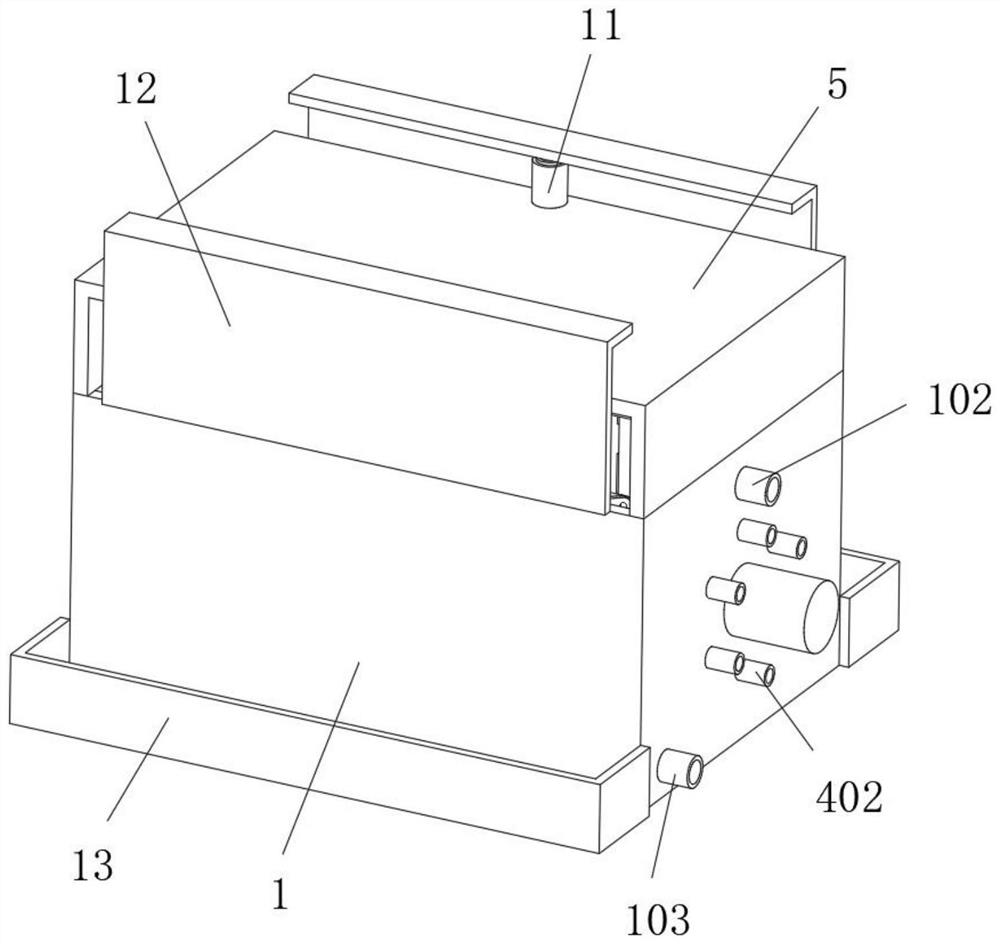

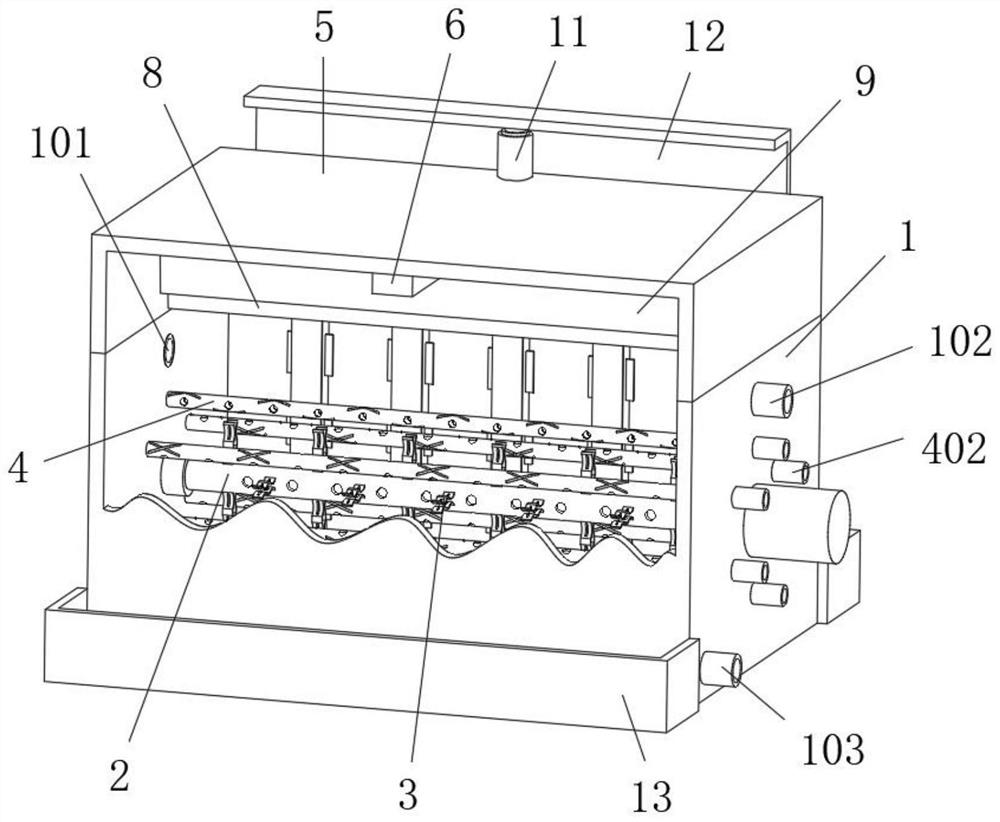

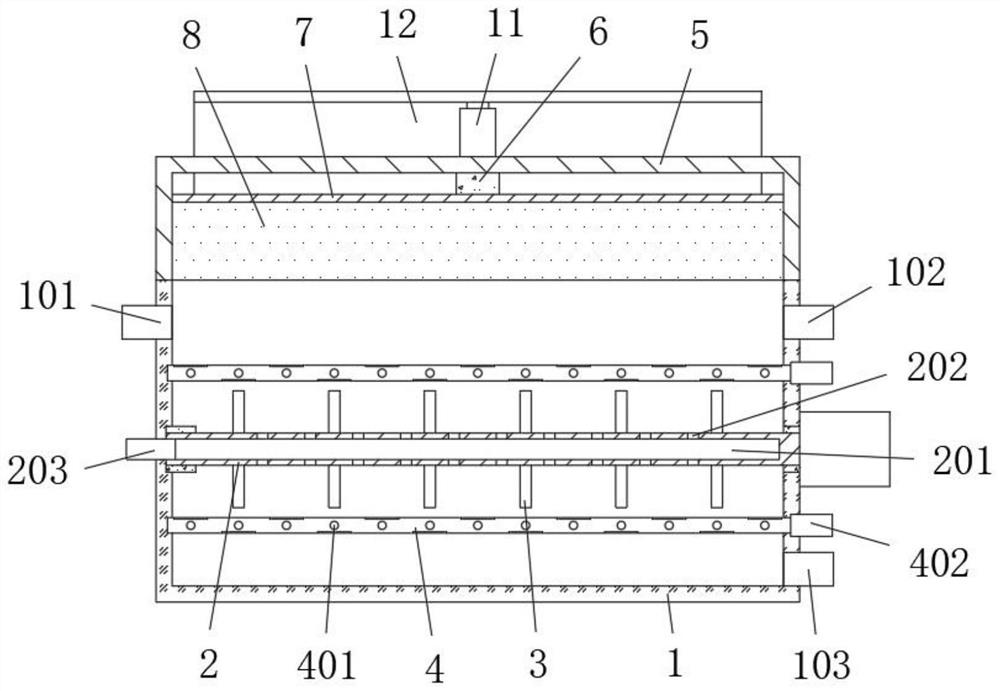

[0032] refer to Figure 1-6 , a stirring type flotation machine for redevelopment and utilization of tailings, comprising a box body 1 with an open top, a stirring mechanism is arranged inside the box body 1, and a foam scraping mechanism is arranged on the top of the box body 1, and the outer walls on both sides of the box body 1 A liquid injection pipe 101 and a feeding pipe 102 are respectively connected to the middle position of the top of the box body 1, and a liquid discharge pipe 103 is connected to the bottom end of the outer wall on one side of the box body 1;

[0033] The stirring mechanism is provided with a stirring rod 2 that is rotatably connected between the inner walls on both sides of the box body 1, and one end of the stirring rod 2 is connected with a driving mechanism, and the end of the stirring rod 2 away from the driving mechanism is provided with a connecting cavity 201, and the connecting cavity 201 A plurality of connection holes 202 are provided on t...

Embodiment 2

[0040] refer to Figure 1-8 , a stirring type flotation machine for redevelopment and utilization of tailings, a fixed frame 5 is fixed between the two sides of the top outer wall of the box body 1, and the two ends of the fixed frame 5 are opened, and the foam scraping mechanism is provided with a device fixed on the fixed frame 5 The electric guide rail 6 at the middle position of the top inner wall, the two ends of the electric guide rail 6 respectively extend toward the two ends of the fixed frame 5, the bottom of the electric guide rail 6 is connected with a fixed plate 7, and the bottom of the fixed plate 7 is fixed with a first foam pusher 8, The bottom end of casing 1 two ends outer wall is all fixed with the receiving box 13 of top opening, and the two ends of fixed frame 5 top outer walls are all fixed with electric telescopic link 11, and the top end of electric telescopic link 11 is connected with baffle plate 12, and baffle plate One end outer wall of 12 is slidab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com