Filter unit and plating apparatus including same

A filter unit and component technology, which is applied in the direction of the device whose axial direction can be reversed, the swirl device, sputtering coating, etc., can solve the problems of poor coating steam density and decreased coating uniformity, and achieve easy to understand effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, the idea of the present invention is not limited to the given embodiments, and those skilled in the art who understand the idea of the present invention can easily propose other inventions or retrogression by adding, changing, deleting other components, etc. within the scope of the same idea. Other embodiments are included in the scope of the idea of the present invention, and these should also be included in the scope of the idea of the present invention.

[0036] Also, components with the same functions within the scope of the same idea shown in the drawings of the respective embodiments will be described using the same reference numerals.

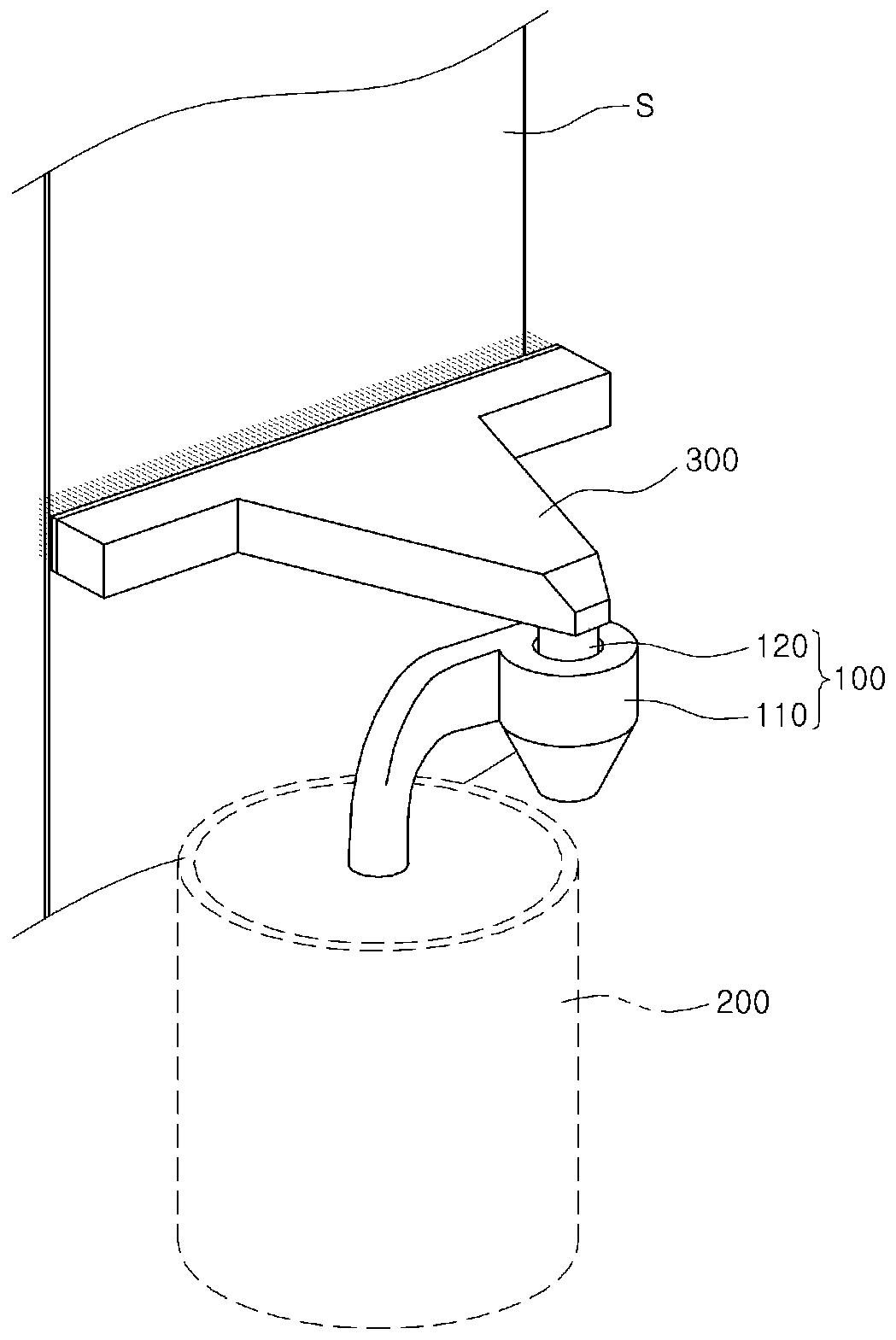

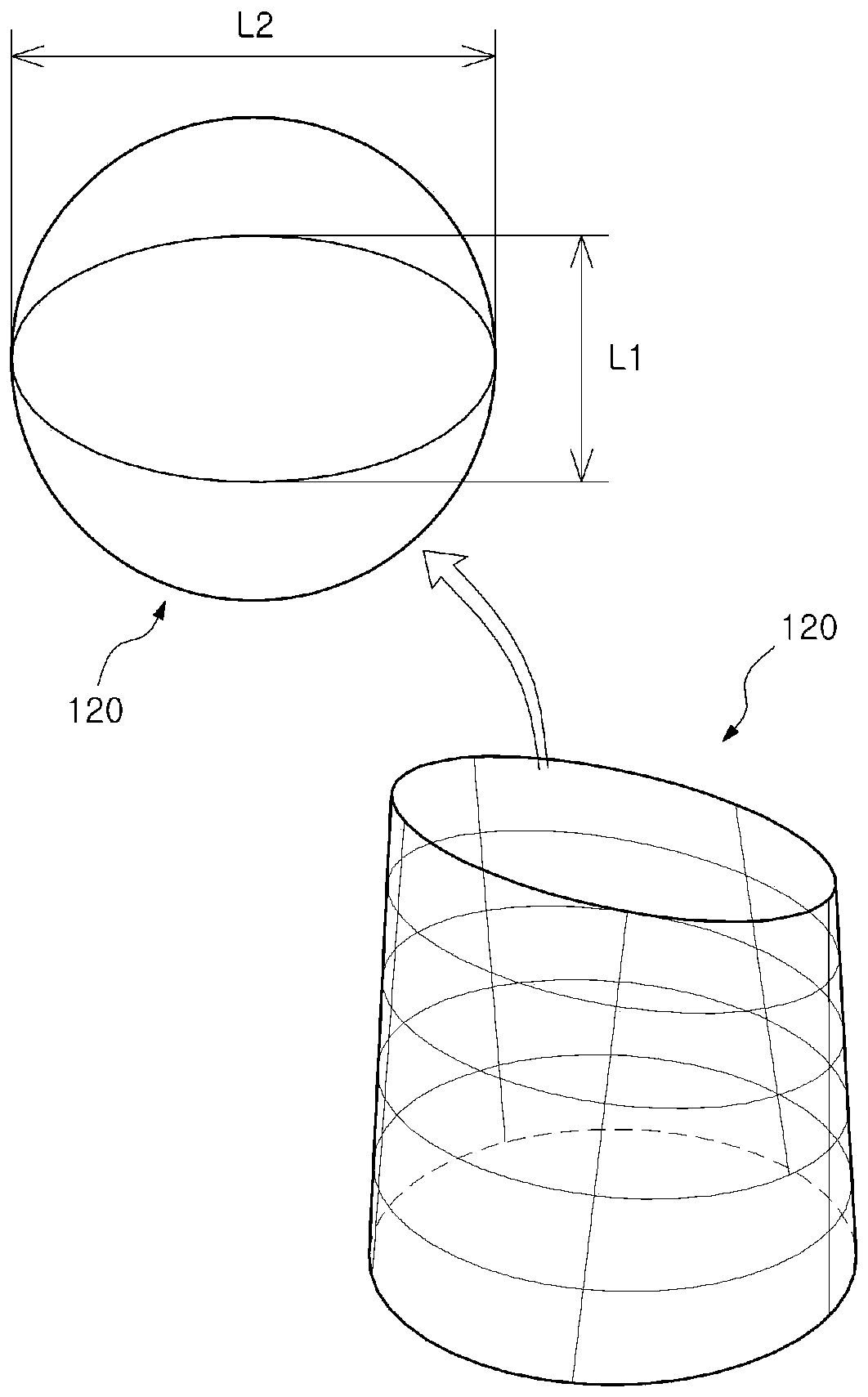

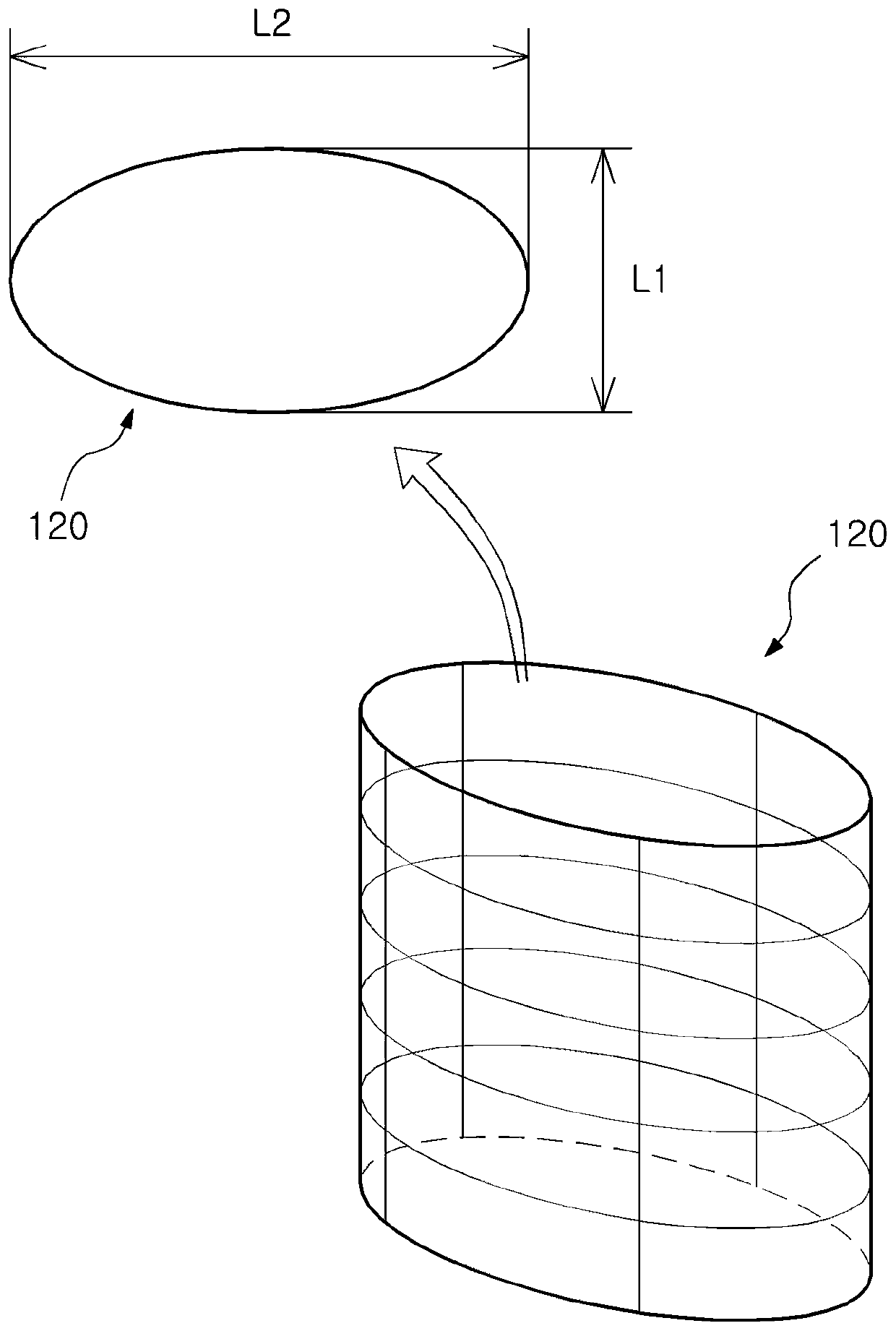

[0037] The precursor of the filter unit 100 of the present invention and the coating device including it is to separate coarse particles generated during the process of heating metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com