Wet instant soybean dietary fiber and preparation method thereof

A technology for soybean dietary fiber and wet state, which is applied to the field of wet ready-to-eat soybean dietary fiber and its preparation, can solve the problems of insignificant physiological adjustment function, high water content of wet soybean residue, unsuitable for direct consumption, and the like, and achieves the content of soluble dietary fiber. High, improve physiological regulation function, overcome the effect of reagent residue and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

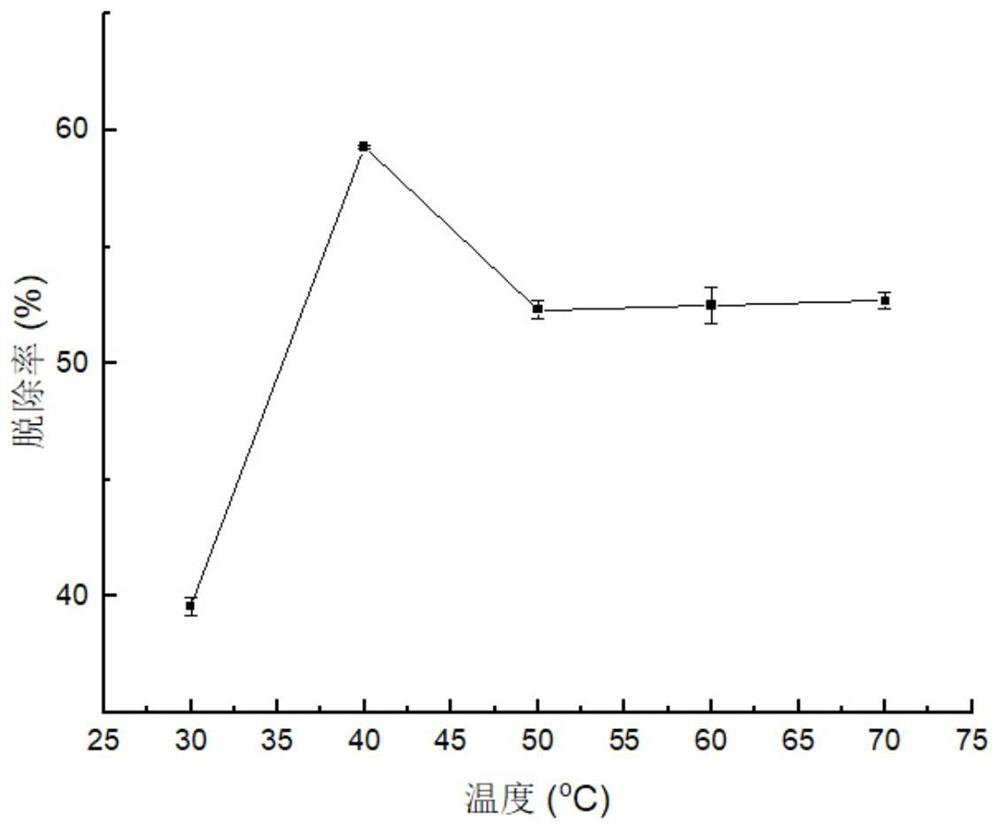

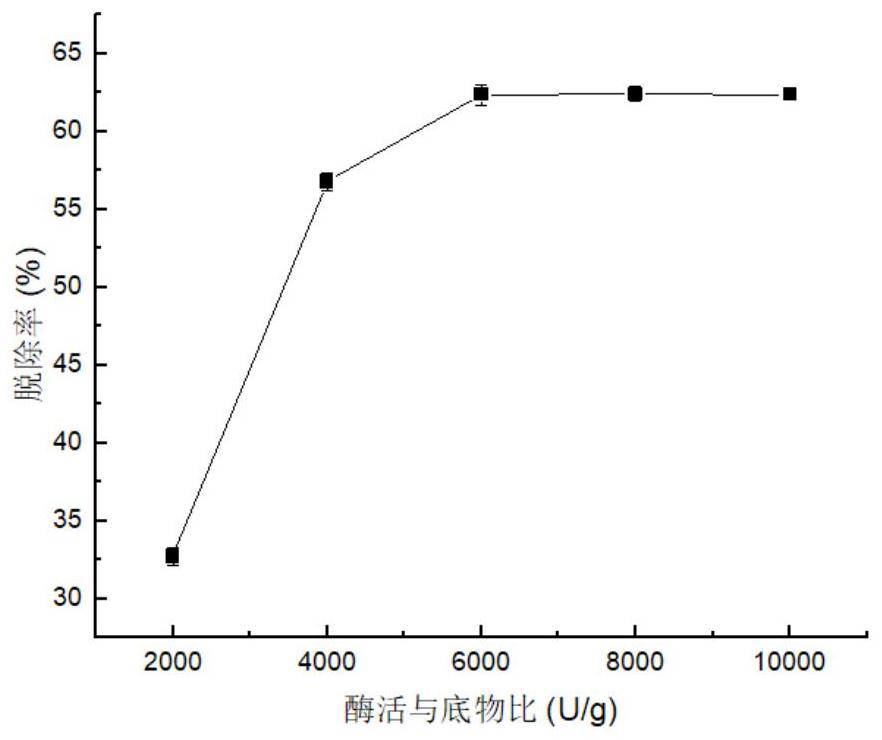

[0085]Step (1), deproteinization: according to the material-to-liquid ratio of 1:20g / mL, the wet bean dregs (the moisture content is about 70%, the soluble dietary fiber content is about 3.5% on a dry basis, the same below) and distilled water are stirred evenly, Add neutral protease according to the ratio of enzyme activity to substrate 8000U / g (protease activity is 50000U / g, the unit of enzyme activity U / g refers to the enzyme activity U contained in 1g of enzyme preparation), heated in a water bath at 45°C for 2h, and heated after the reaction To 100 ℃, water bath for 15min, do enzyme inactivation and deodorization treatment, filter, keep filter residue;

[0086] Step (2), decolorization: according to the ratio of material to liquid 1:20g / mL, add H with a concentration of 7% to the bean dregs obtained in step (1). 2 O 2 , and then add 1 mol / L NaOH solution to adjust the pH value to 10, stir evenly, react in a water bath at 40 °C for 3 h, filter, and leave the filter residu...

Embodiment 2

[0092] Step (1), deproteinization: the ratio of material to liquid is 1:20g / mL, the wet bean dregs and distilled water are stirred evenly, and neutral protease is added according to the ratio of enzyme activity to substrate 8000U / g (protease activity is 50000U / g), 45 ℃ water bath heating for 2h, after the reaction, heated to 100 ℃, water bath for 15min, do enzyme inactivation and deodorization treatment, filter, keep filter residue;

[0093] Step (2), decolorization: according to the ratio of material to liquid 1:20g / mL, add H with a concentration of 7% to the bean dregs obtained in step (1). 2 O 2 , and then add 1 mol / L NaOH solution to adjust the pH value to 10, stir evenly, react in a water bath at 40 °C for 3 h, and filter;

[0094] Step (3), washing: the filter residue is washed 3-5 times with distilled water until the filtrate is neutral;

[0095] Step (4), high-pressure homogenization activation: according to the material-to-liquid ratio of 1:10g / mL, mix the bean dreg...

Embodiment 3

[0099] Step (1), deproteinization: the ratio of material to liquid is 1:20g / mL, the wet bean dregs and distilled water are stirred evenly, and neutral protease (protease activity is 50000U / g) is added according to the ratio of enzyme activity to substrate 8000U / g. Heating in a water bath for 2 hours at 45°C, heating to 100°C after the reaction, in a water bath for 15 minutes, for enzyme inactivation and deodorization treatment, filtering, and leaving the filter residue;

[0100] Step (2), decolorization: according to the ratio of material to liquid 1:20g / mL, add H with a concentration of 7% to the bean dregs obtained in step (1). 2 O 2 , and then add 1 mol / L NaOH solution to adjust the pH value to 10, stir evenly, react in a water bath at 40 °C for 3 h, filter, and leave the filter residue;

[0101] Step (3), washing: the filter residue is washed 3-5 times with distilled water until the filtrate is neutral;

[0102] Step (4), high-pressure homogenization activation: accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com