Method for determining boundary streamline of gap nozzle for creating wide and thin water curtain

A boundary and spout technology, applied in separation methods, chemical instruments and methods, use of liquid separation agents, etc., can solve the problems of uncontrolled boundary flow, high outflow velocity, flow field instability, etc., and reduce local resistance and eddy current resistance. , The effect of improving the uniformity of the outflow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

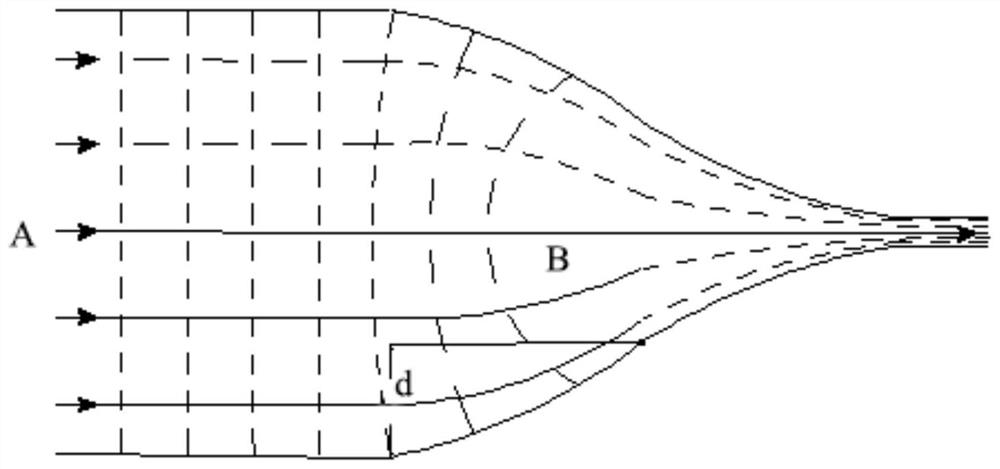

[0033] see image 3 , Figure 5 , the cross-section of the slit spout of the present invention is a streamline shape with a wide top and a narrow bottom, including an upper parallel section and a lower contraction section; the method for determining the streamline of the slit spout boundary of building a wide and thin water curtain based on the slit spout comprises the following steps:

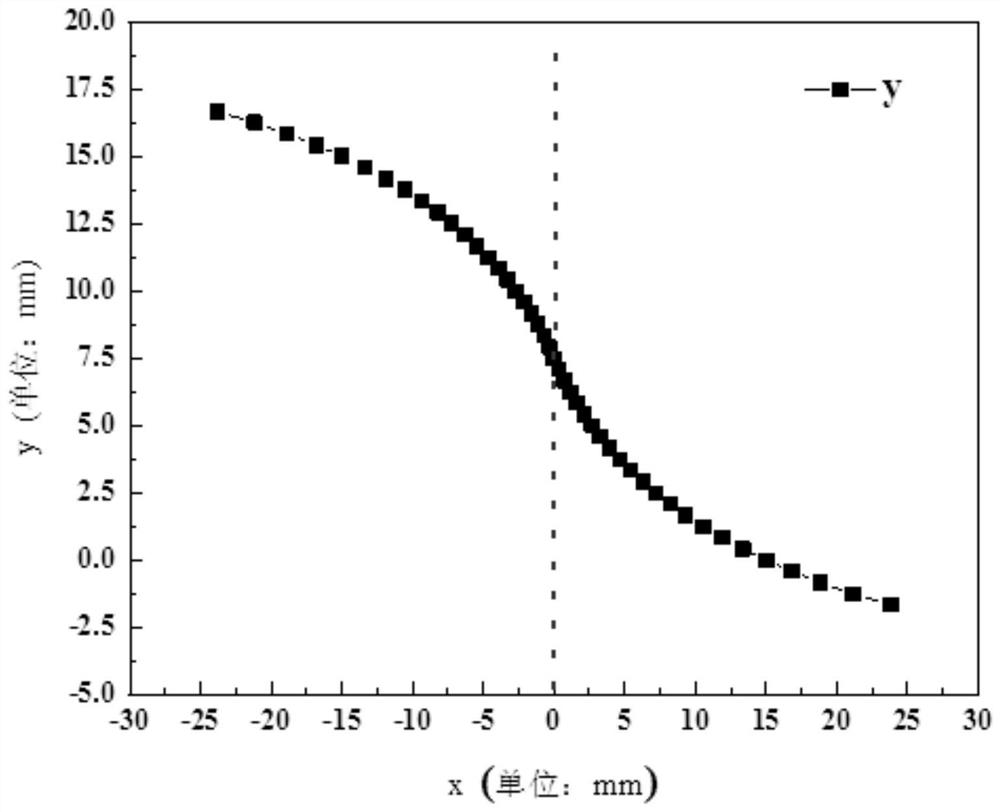

[0034] (1) Derivation of the streamlined boundary equation:

[0035] see figure 1 , analyze the streamlined gap spout model according to the planar potential flow theory of fluid mechanics. The water flow from the parallel section A at the entrance of the spout entering the constricted section B is regarded as the composite flow of parallel plane flow and point sink, and the flow from the constricted section B to the spout exit is regarded as As a composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com