Torque-sensor-free iron loss experimental measurement method for high-speed electro-magnetic motor

A measurement method and electric excitation technology, applied in the direction of motor generator testing, measuring electricity, measuring devices, etc., can solve the problem that the shaft power cannot calculate the iron loss, and achieve the effect of correcting the iron loss model parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

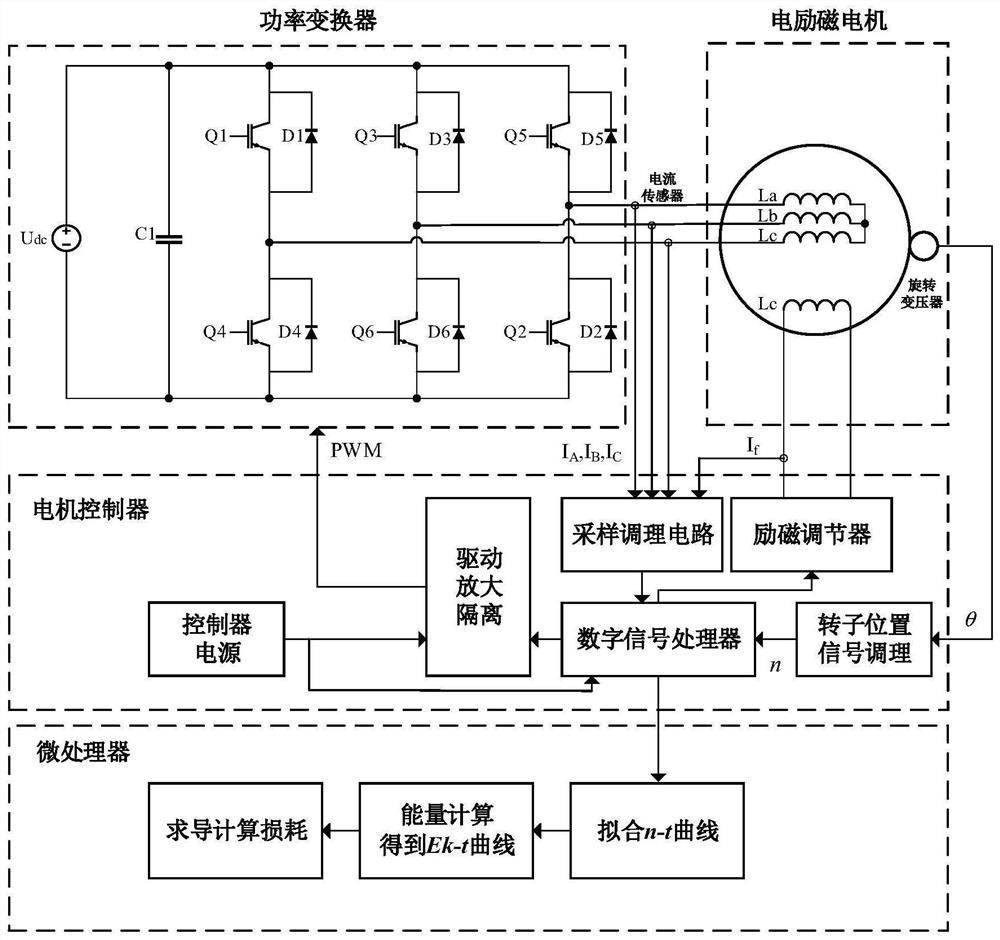

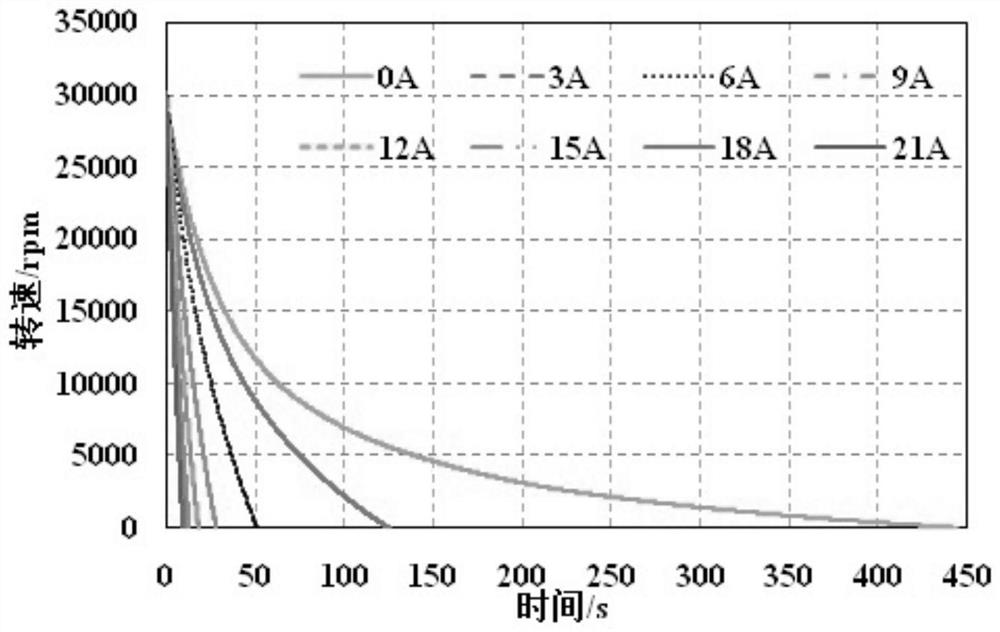

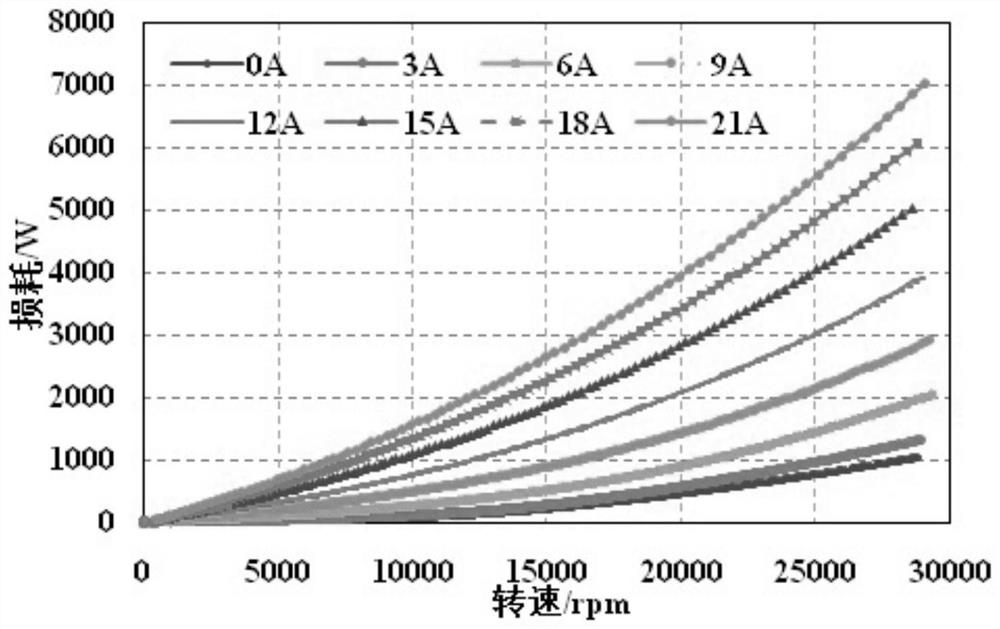

[0035] figure 1 For this embodiment, the system block diagram of the high-speed electric excitation motor adopting the iron loss experiment measurement method without torque sensor, the specific implementation steps are as follows:

[0036] (1) Acquisition of position and rotational speed signals: the rotary transformer is used to acquire the rotor position signal θ, the rotor position angle signal is sent to the motor controller, and the motor rotational speed n is calculated through the pre-written controller program;

[0037] (2) Power converter: The power converter uses a three-phase full-bridge inverter circuit to provide drive for the motor. When the motor is running without load, detect the speed n and the armature current I A , I B , I C The signal is sent to the motor controller, and the digital signal processor provides PWM wave signals to the power converter through the amplified isolation circuit according to the current operating conditions to control the openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com