An Accurate Prediction Method for Thrust of Permanent Magnet Synchronous Linear Motor Considering Air Gap Fluctuation

A permanent magnet synchronous linear, motor thrust technology, applied in motor control, AC motor control, electrical components, etc., can solve the problem of little research on the influence of motor thrust reaction, and achieve simple and clear principles and calculation processes, fast analytical quantitative analysis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

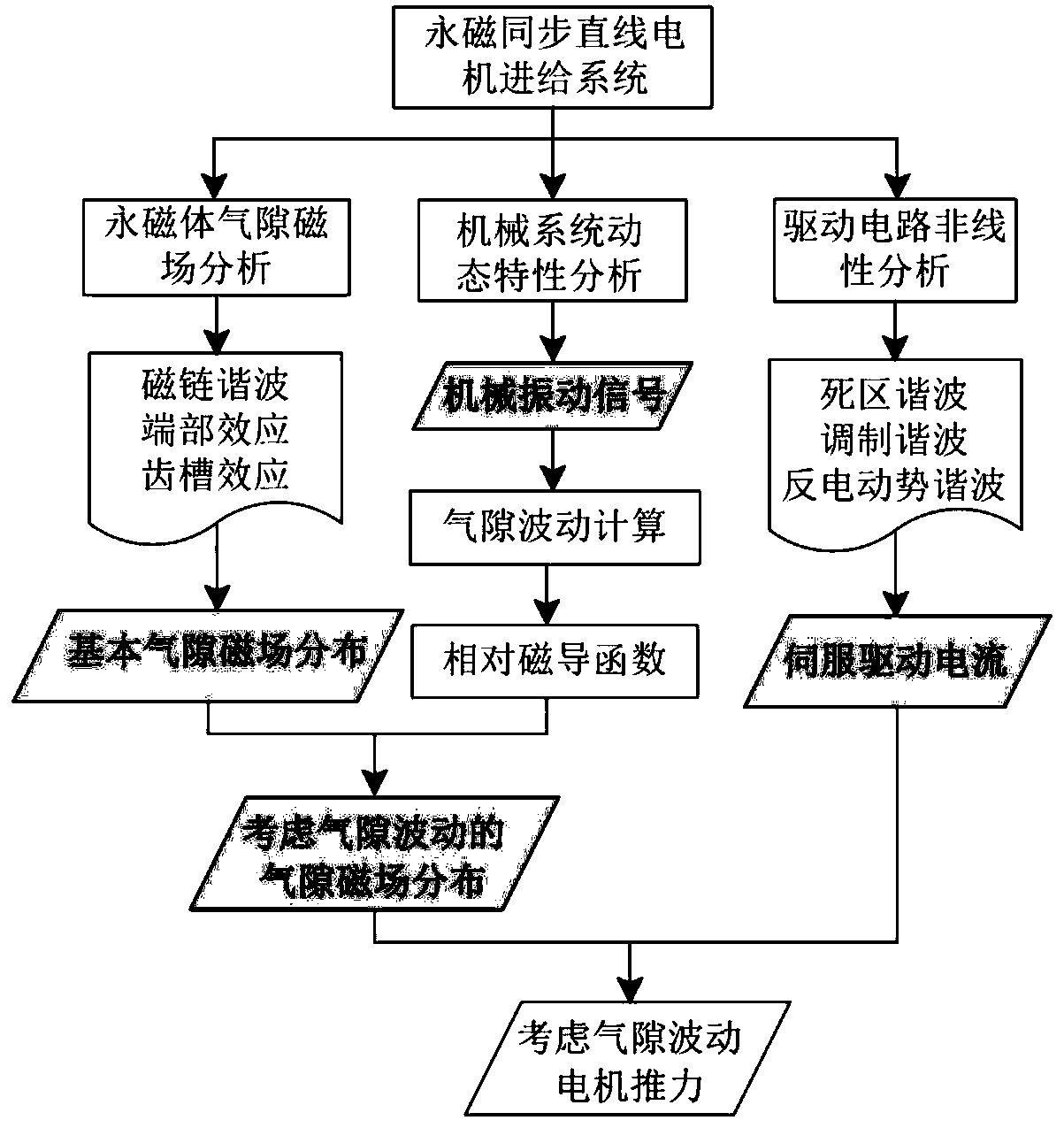

[0046] The present invention is a method for accurately predicting the thrust of a permanent magnet synchronous linear motor considering air gap fluctuations, such as figure 1 shown, including the following steps,

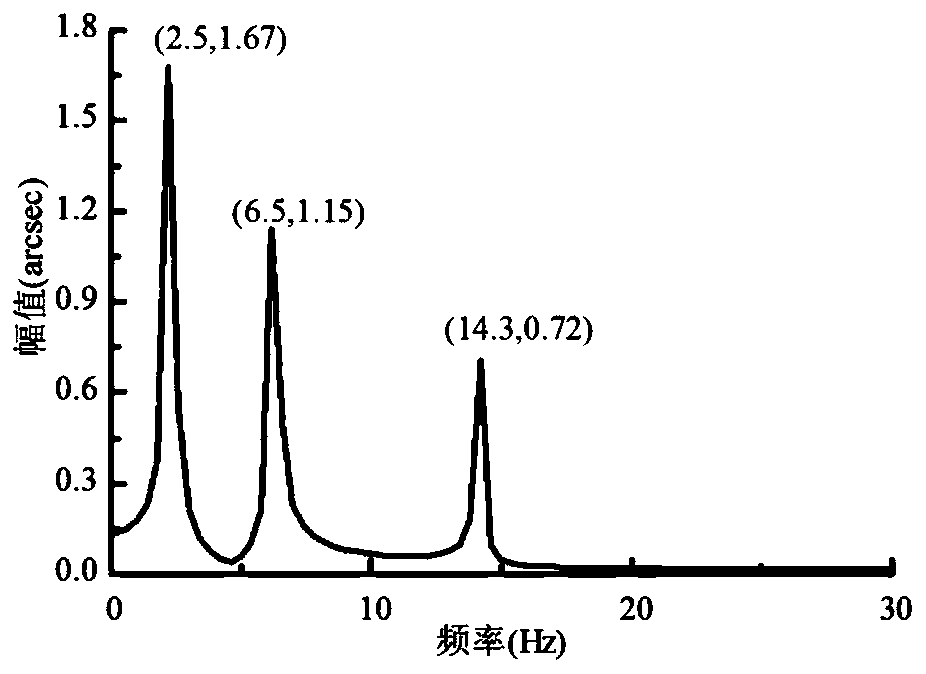

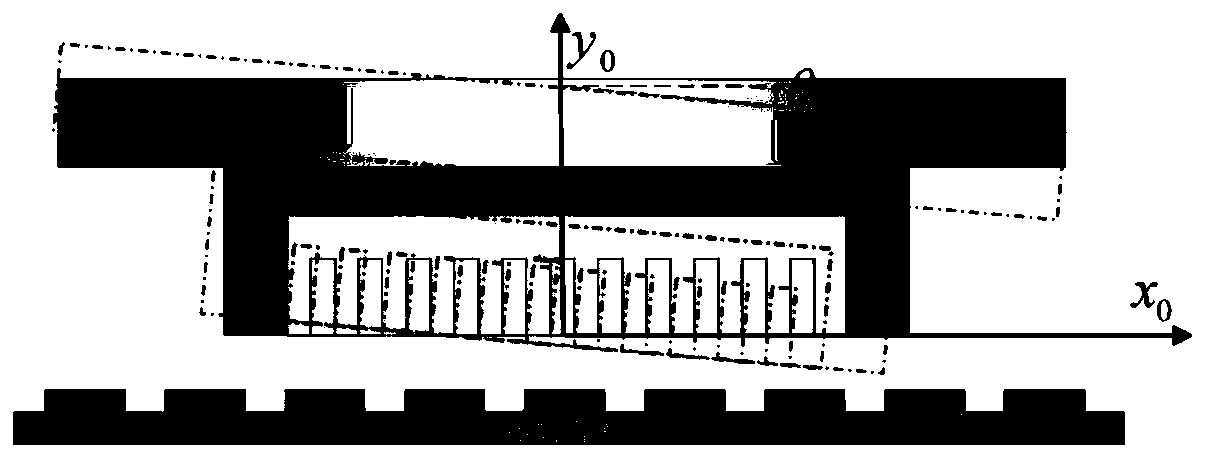

[0047] Step 1: Obtain the torsional oscillation angular displacement θ(t) of the workbench of the permanent magnet synchronous linear motor feed system through the experimental test or simulation model, and calculate the actual air gap g of the motor after considering the mechanical oscillation according to the motor installation position and mechanical structure parameters '(x 0 ,t), where x 0 Indicates different positions in the motor mover coordinate system.

[0048] Step 2: Introduce the relative permeability function to describe the influence of the motor air gap fluctuati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com