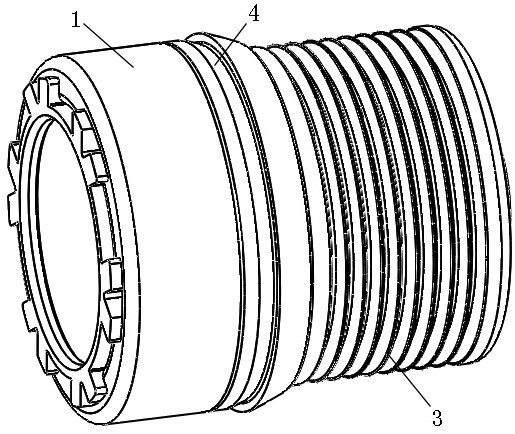

Assembled belt wheel component

An assembled, pulley technology, applied to components with teeth, belts/chains/gears, hoisting devices, etc., can solve the problems of roller failure, loose connection of steel pipes, etc., to extend service life and low cost , easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

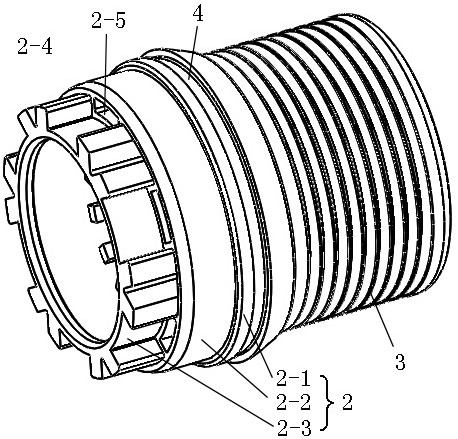

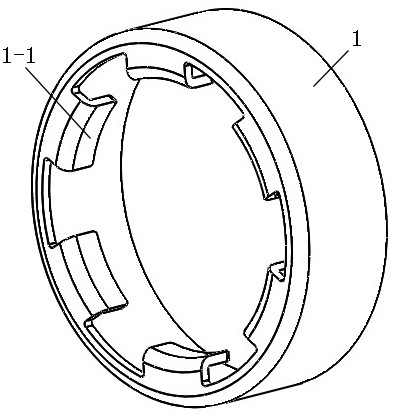

[0033] Embodiment one, such as Figure 1 to Figure 3 As shown, an assembled pulley assembly includes a pulley body made of plastic material and a connecting sleeve 1 made of rigid material, the connecting sleeve 1 is used for interference fit connection with a steel pipe, and the pulley body It includes a belt installation part 3 for installing the belt and a connection sleeve installation part 2 for connecting with the connection sleeve 1 . The connection sleeve 1 is axially sleeved on the connection sleeve installation part 2, and the outer peripheral side of the connection sleeve installation part 2 is provided with a limiting groove communicating with one end in the axial direction, and the inner peripheral side of the connection sleeve 1 is provided with The limiting protrusion 1-1 is assembled and connected with the limiting groove. The pulley body also includes a steel pipe press-fitting part, the first axial end of the steel pipe press-fitting part is connected to the...

Embodiment 2

[0046] Embodiment two, such as Figure 4 with Figure 5 As shown, the difference from the first embodiment is that the belt installation part 3 can be an O-shaped belt installation part, which is used for assembling with the O-shaped belt.

Embodiment 3

[0047] Embodiment three, such as Image 6 with Figure 7 As shown, the difference from Embodiment 1 is that the belt installation part 3 may be a timing belt installation part for assembling with the timing belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com