Bionic active static pressure gas bearing

A static pressure gas bearing, active technology, applied in the direction of air cushion bearings, bearings, shafts and bearings, to achieve high stiffness and adjustable stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

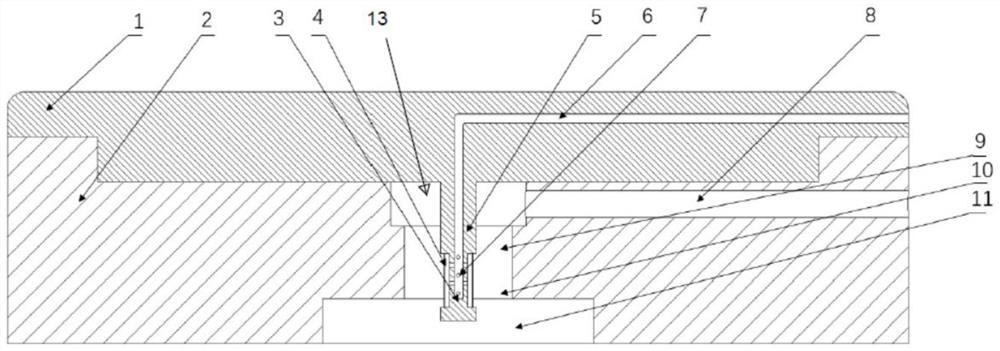

Method used

Image

Examples

Embodiment 2

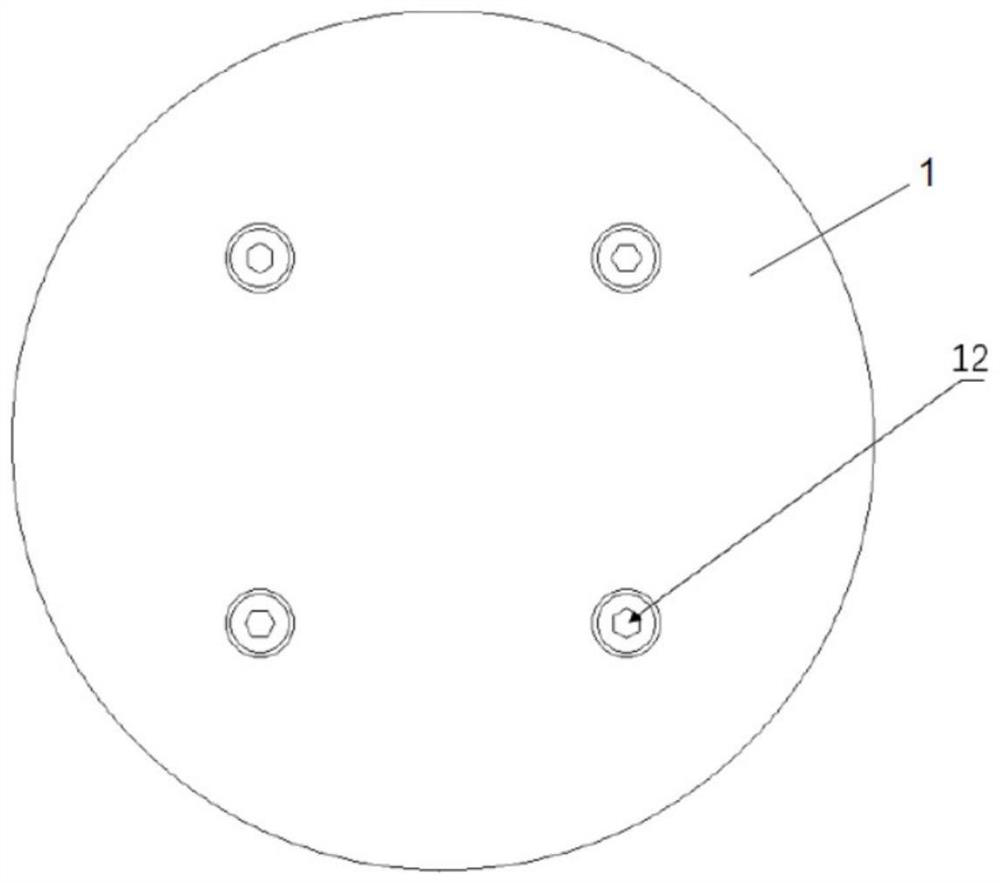

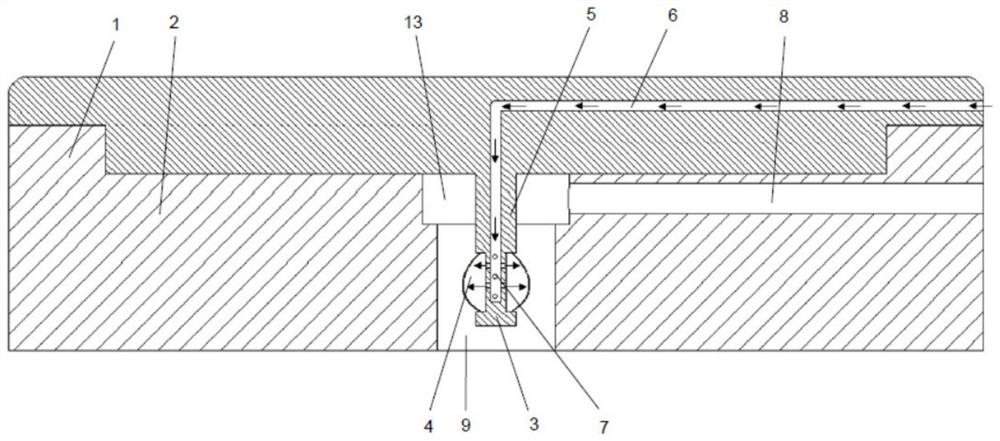

[0046] The basic structure of this embodiment 2 is the same as that of embodiment 1, except that the bionic airflow regulator is no longer fixedly connected with the bearing end cover, but is constructed as a separate component. A sealant is used to bond the bionic airflow regulator to the wall of the airway, and an air supply channel is provided on the bearing end cover to connect with the bionic airflow regulator to realize air supply. The top view of the independent bionic airflow regulator is as follows: Figure 5 As shown, the overall bearing structure is as Figure 4 shown.

Embodiment 3

[0048] The basic structure of this embodiment 3 is the same as that of embodiment 1, and a restrictor is arranged on the end surface of the bearing, such as Figure 6 shown.

Embodiment 4

[0050] The basic structure of this embodiment 4 is the same as that of embodiment 1, the difference is that four restrictors are arranged on the end surface of the bearing, such as Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com