Prefabricated foundation embedded structure and installation method thereof

A prefabricated and pre-embedded technology, applied in infrastructure engineering, building construction, architecture, etc., can solve the problems of difficult to precisely control its own size, large randomness of bracket production, positioning and elevation deviation, etc. Reliable, avoids the effect of corrective work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

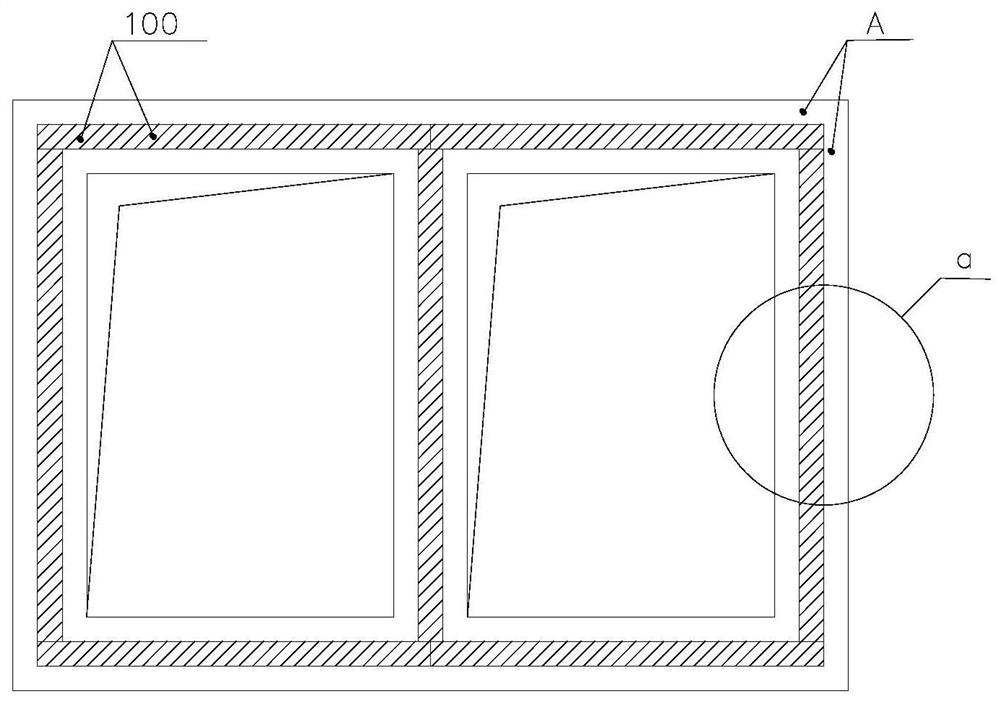

[0054] Embodiment 1 Prefabricated foundation embedded structure (strip)

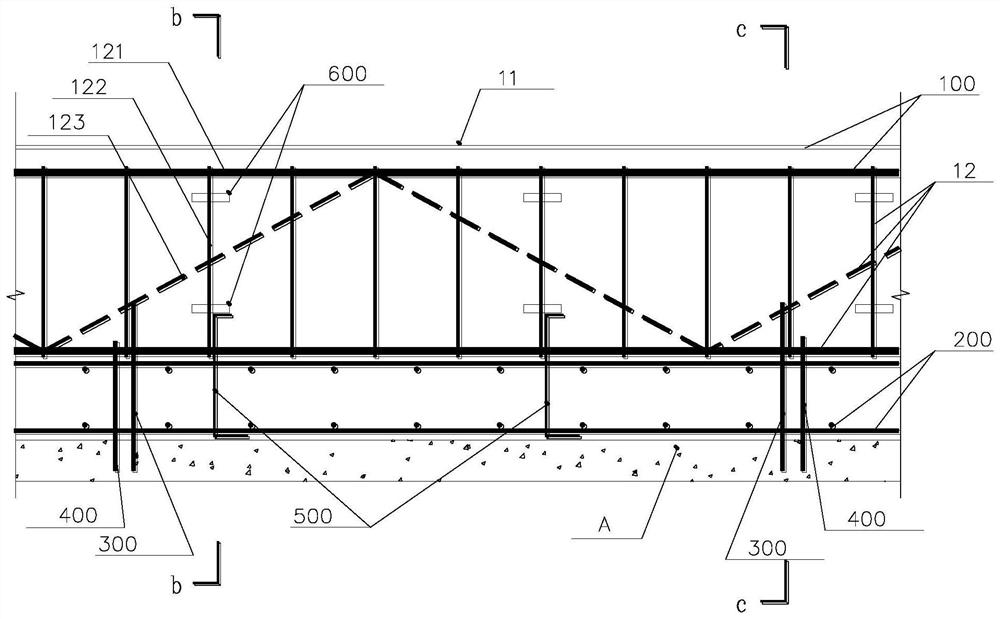

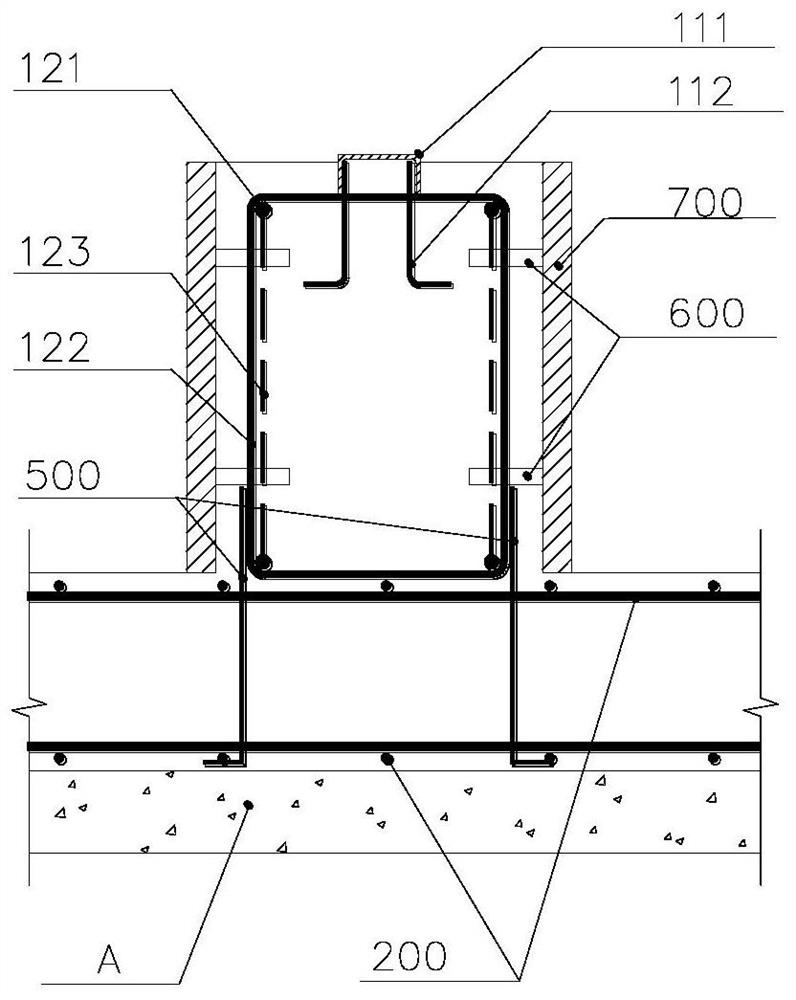

[0055] The prefabricated foundation pre-embedded structure of this embodiment 1 is strip-shaped, correspondingly installed in the strip-shaped pouring foundation concrete cushion A, such as figure 1 shown. Specifically, see the attached Figure 1-9 As shown, the strip-shaped prefabricated foundation embedded structure includes an integrated embedded frame 100; the integrated embedded frame includes an embedded part assembly 11 and a steel skeleton 12; the embedded part assembly includes an embedded part 111 and Embedded part anchor bars 112; the steel bar skeleton 12 includes longitudinal steel bars 121, vertical steel bars 122, and oblique steel bars 123; several vertical steel bars are arranged at intervals, and four longitudinal steel bars are interspersed in each vertical steel bar, and are welded The method is correspondingly fixed on the four inner corners of the vertical reinforcement; the obliq...

Embodiment 2

[0063] Embodiment 2 Prefabricated foundation embedded structure (block shape)

[0064] The prefabricated foundation pre-embedded structure of this embodiment 1 is in the shape of a plate, which is correspondingly installed in the plate-shaped pouring foundation concrete cushion A, such as figure 1 shown. Specifically, see the attached Figure 9-12 As shown, the plate-shaped prefabricated foundation embedded structure includes an integrated embedded frame 100; the integrated embedded frame includes an embedded part assembly 11 and a steel skeleton 12; the embedded part assembly includes an embedded part 111 and a pre-embedded Embedded anchor bars 112; the reinforcement skeleton 12 includes longitudinal reinforcement bars 121, vertical reinforcement bars 122, and oblique reinforcement bars 123; The reinforcement is connected end to end to form a broken line, and the oblique reinforcement is connected to each vertical reinforcement, and the three are welded to each other to for...

Embodiment 3

[0067] A method for installing the foundation embedded structure as described in Embodiment 1-2, comprising the steps of:

[0068] (1) Pouring foundation concrete cushion A;

[0069] (2) Lay out the wires according to the diagram to determine the position of the integrated pre-embedded framework 100;

[0070] (3) Install the base plate reinforcement member 200;

[0071] (4) base plate inserting bar 500 is installed, and the foundation base plate reinforcement member 200 is bound firmly; The reinforcement member 200 is separated, so the bottom plate insertion bar 500 is added to connect the reinforcement skeleton 12 and the foundation bottom plate reinforcement member 200 .

[0072] (5) setting out the position of determining the vertical positioning regulator 300 and the horizontal positioning regulator 400, and drilling holes on the foundation concrete pad A;

[0073] (6) The lengthened expansion bolt 32 of the vertical positioning regulator 300 is installed in the borehol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com