Vacuum bag film with heating function and preparation method and application thereof

A vacuum film and vacuum bag technology, applied in the field of packaging, can solve the problems of resource and cost waste, large autoclave, unfavorable industrialization development, etc., and achieve the effect of reducing energy loss and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A vacuum bag having a fever function, a cross-sectional structure, such as figure 1 As shown, a vacuum film layer 1 and a conductive fever layer 2 are included;

[0046] Among them, the vacuum film layer 1 is a nylon film (Shanghai Baoyue, LVF230B) having a thickness of 75 μm;

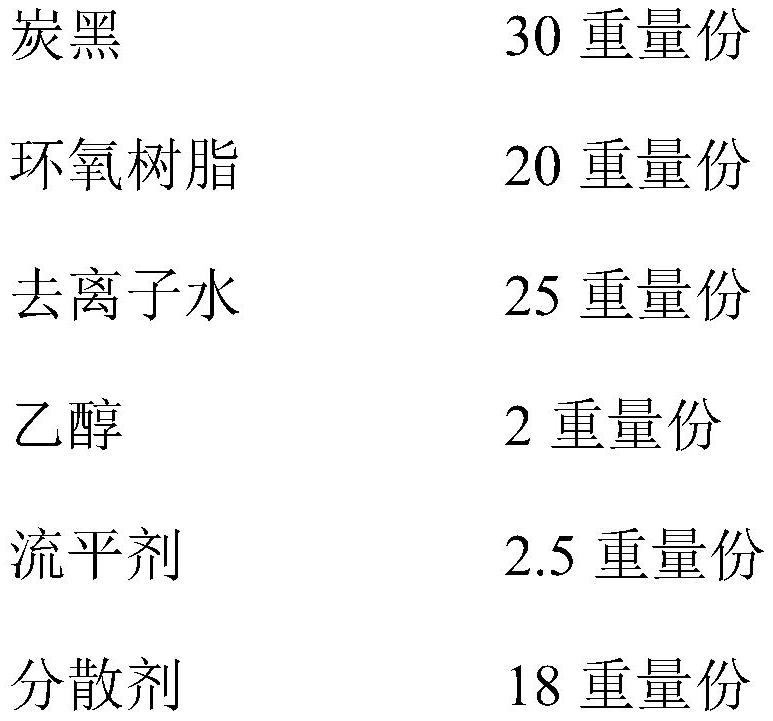

[0047] The conductive heat generating layer 2 has a thickness of 50 μm, and the material includes the following components according to the weight:

[0048]

[0049]

[0050] Among them, the epoxy resin is derived from Yansen, 5003, and the leveling agent is derived from BYK-420, and the dispersant is derived from Byk-180, and the defoaming agent is derived from Bik-016;

[0051] The method of preparing the vacuum bag film provided in this example includes the steps of:

[0052] (1) Carbon black, epoxy resin, deionized water, ethanol, leveling agent, dispersant, and antifoaming agent are mixed under conditions of 1000 rpm at a rotational speed to obtain a carbon-based conductive ink;

[0053] (2...

Embodiment 2

[0055] A vacuum bag film having a heat generating function, which is the same as that of Example 1; including a vacuum film layer and a conductive heat excitation layer;

[0056] Among them, the vacuum film layer is a nylon film having a thickness of 50 μm; (Shanghai Baoyue, LVF230B);

[0057] The electrically conductive heat-insulating layer has a thickness of 30 μm, and the material includes the following components according to the weight:

[0058]

[0059] Among them, the polyurethane resin is derived from river, H-28N, and the leveling agent originated from Byk-420, the dispersant derived from Byk-180, and the defoaming agent originated from Bike Chemical, BYK-016;

[0060] The method of preparing the vacuum bag film provided in this example includes the steps of:

[0061] (1) A carbon nanotube, polyurethane resin, deionized water, n-propanol, a leveling agent, dispersant, and antifoaming agent are mixed under a rotational speed of 900 rpm, resulting in a carbon-based condu...

Embodiment 3

[0064] A vacuum bag film having a heat generating function, which is the same as that of Example 1; including a vacuum film layer and a conductive heat excitation layer;

[0065] Among them, the vacuum film layer is a nylon film (Shanghai Baoyue, LVF230B) having a thickness of 100 μm;

[0066] The electrically conductive heat-insulating layer has a thickness of 100 μm, and the material includes the following components according to the weight:

[0067]

[0068] Among them, acrylic resin is derived from Han Hua, Soluryl-120, graft from Byk-420, dispersant from manufacturer Byk-180, defoamer comes from Bike Chemical, Model BYK- 016;

[0069] The method of preparing the vacuum bag film provided in this example includes the steps of:

[0070] (1) Grain, acrylic resin, deionized water, isopropanol, leveling agent, dispersant, and antifoaming agent are mixed under conditions of a rotational speed of 1200 rpm to obtain a carbon-based conductive ink;

[0071] (2) The carbon-based conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com