Flexible phase change composite material with cross-linked network structure and preparation method thereof

A phase-change composite material and network structure technology, which is applied in the field of flexible phase-change composite materials with a cross-linked network structure and its preparation, can solve the problems of poor flexibility and other problems, and achieve good bending flexibility, good tensile strength, The effect of easy cutting and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

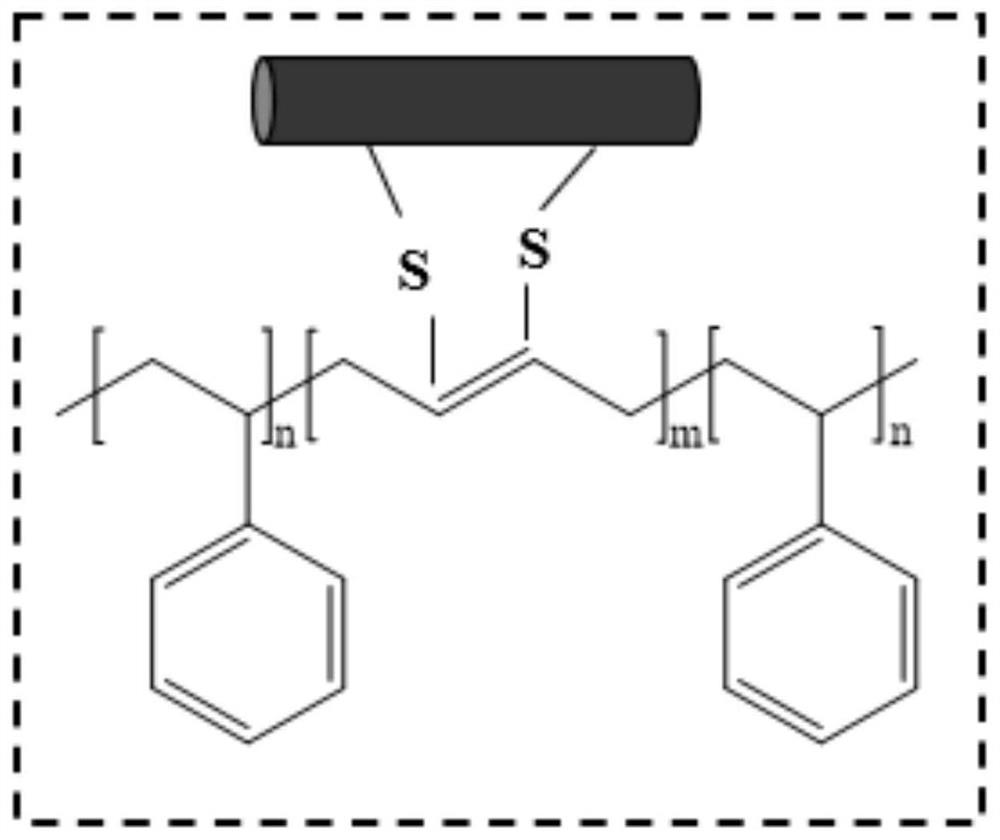

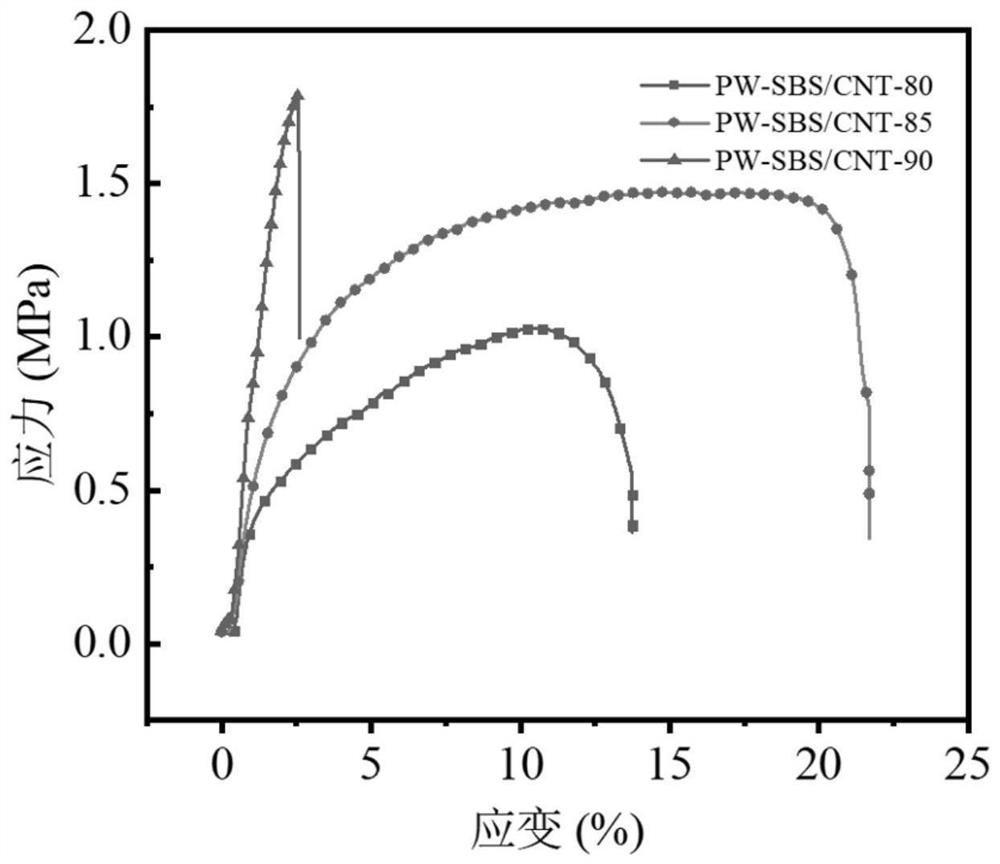

[0032] Example 1 Preparation of a flexible phase-change composite material with a crosslinked network structure

[0033] First, put the solid-liquid phase change material paraffin on a heating platform higher than its melting temperature for melting, then add 20wt.% SBS and 2wt.% CNT powder to the molten paraffin successively, and place the reaction vessel at 180 In a heating pot at ℃, the mixture was sheared by a high-speed shearer to achieve uniform dispersion of SBS and CNTs in the molten paraffin medium. After shearing for 1 hour, a phase change material / polymer mixture with uniformly dispersed carbon nanotubes was obtained.

[0034]Secondly, transfer the mixture to a mechanical stirring device, keep the heating state at 180°C, add 0.2wt.% sulfur powder to the mixture as a chemical cross-linking agent for SBS and CNT, and process it with medium-speed mechanical stirring for 2 hours. After standing and cooling The flexible phase change composite material PW-SBS / CNTs-80 wit...

Embodiment 2

[0036] Example 2 Preparation of a flexible phase-change composite material with a cross-linked network structure

[0037] First, put the solid-liquid phase change material paraffin on a heating platform higher than its melting temperature for melting, then add 15wt.% SBS and 2wt.% CNT powder to the molten paraffin successively, and place the reaction vessel at 180 In a heating pot at ℃, the mixture was sheared by a high-speed shearer to achieve uniform dispersion of SBS and CNTs in the molten paraffin medium. After shearing for 1 hour, a phase change material / polymer mixture with uniformly dispersed carbon nanotubes was obtained.

[0038] Secondly, transfer the mixture to a mechanical stirring device, keep the heating state at 180°C, add 0.2wt.% sulfur powder to the mixture as a chemical cross-linking agent for SBS and CNT, and process it with medium-speed mechanical stirring for 2 hours. After standing and cooling The flexible phase change composite material PW-SBS / CNTs-85 w...

Embodiment 3

[0040] Example 3 Preparation of a flexible phase-change composite material with a cross-linked network structure

[0041] First, put the solid-liquid phase change material paraffin on a heating platform higher than its melting temperature for melting, then add 10wt.% SBS and 2wt.% CNT powder to the molten paraffin successively, and place the reaction vessel at 180 In a heating pot at ℃, the mixture was sheared by a high-speed shearer to achieve uniform dispersion of SBS and CNTs in the molten paraffin medium. After shearing for 1 hour, a phase change material / polymer mixture with uniformly dispersed carbon nanotubes was obtained.

[0042] Secondly, transfer the mixture to a mechanical stirring device, keep the heating state at 180°C, add 0.2wt.% sulfur powder to the mixture as a chemical cross-linking agent for SBS and CNT, and process it with medium-speed mechanical stirring for 2 hours. After standing and cooling The flexible phase change composite material PW-SBS / CNTs-90 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com