Polypropylene corrugated pipe

A bellows and polypropylene technology, applied in the field of bellows materials, can solve the problems of high cost, insufficient heat resistance, easy cracking, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

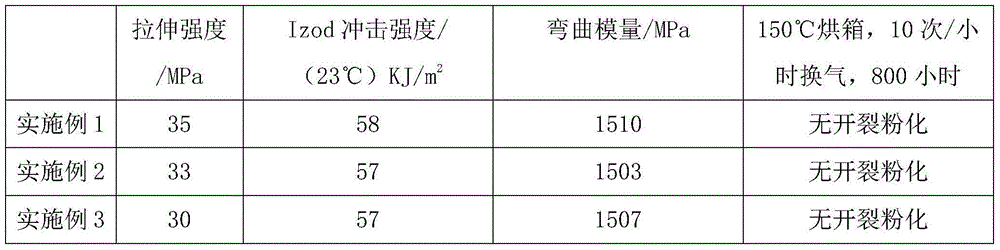

Examples

Embodiment 1

[0013] A kind of polypropylene bellows proposed in this embodiment is made of the following raw materials in parts by weight:

[0014] Ethylene-propylene copolymer polypropylene: 105 parts; tetrabromobisphenol S bis(2,3-dibromopropyl) ether: 9 parts; antimony trioxide: 5 parts; β-(3,5-di-tert-butyl- 4-Hydroxyphenyl) propionate n-octadecyl ester: 0.35 parts; Dilaurate thiodipropionate: 0.4 parts; Poly(1-hydroxyethyl-2,2,6,6,-tetramethyl -4-hydroxypiperidine) succinate: 0.7 parts; Zinc stearate: 1.0 parts; Calcium stearate: 0.4 parts; Sodium benzoate: 0.2 parts; Pimelic acid / calcium stearate complex: 0.3 share;

[0015] According to the above ratio, prepare the polypropylene corrugated pipe according to the following steps: S1: weigh each raw material by weight; S2: put the raw materials obtained in S1 into a mixer for mixing, and the mixing time is 3.5 minutes ; S3: Add the material mixed in S2 into a twin-screw extruder to extrude and granulate to obtain the corrugated pipe ...

Embodiment 2

[0017] A kind of polypropylene bellows proposed in this embodiment is made of the following raw materials in parts by weight:

[0018] Ethylene-propylene copolymer polypropylene: 110 parts; tetrabromobisphenol S bis(2,3-dibromopropyl) ether: 8 parts; antimony trioxide: 6 parts; β-(3,5-di-tert-butyl- 4-Hydroxyphenyl) propionate n-octadecyl ester: 0.2 parts; Dilaurate thiodipropionate: 0.5 parts; Poly(1-hydroxyethyl-2,2,6,6,-tetramethyl -4-hydroxypiperidine) succinate: 0.6 parts; Zinc stearate: 1.2 parts; Calcium stearate: 0.3 parts; Sodium benzoate: 0.3 parts; Pimelic acid / calcium stearate complex: 0.2 parts share;

[0019] According to the above proportions, the polypropylene corrugated pipe was prepared according to the following steps: S1: weigh each raw material by weight; S2: put the raw materials obtained in S1 into a mixer for mixing, and the mixing time was 5 minutes; S3: Add the material that has been mixed in S2 into a twin-screw extruder to extrude and granulate to...

Embodiment 3

[0021] A kind of polypropylene bellows proposed in this embodiment is made of the following raw materials in parts by weight:

[0022] Ethylene-propylene copolymer polypropylene: 100 parts; tetrabromobisphenol S bis(2,3-dibromopropyl) ether: 10 parts; antimony trioxide: 4 parts; β-(3,5-di-tert-butyl- 4-Hydroxyphenyl) propionate n-octadecyl ester: 0.5 parts; Dilaurate thiodipropionate: 0.3 parts; Poly(1-hydroxyethyl-2,2,6,6,-tetramethyl -4-hydroxypiperidine) succinate: 0.8 parts; Zinc stearate: 0.8 parts; Calcium stearate: 0.5 parts; Sodium benzoate: 0.1 parts; Pimelic acid / calcium stearate complex: 0.4 share;

[0023] According to the above ratio, the polypropylene corrugated pipe was prepared according to the following steps: S1: Weigh each raw material according to parts by weight; S2: Put the raw materials obtained in S1 into a mixer for mixing, and the mixing time is 2 minutes; S3: Add the material that has been mixed in S2 into a twin-screw extruder to extrude and granu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com