Insulating material with scorching resistance and preparation method thereof

A technology of insulating materials and performance, applied in the direction of organic insulators, insulators, plastic/resin/wax insulators, etc., can solve the problems of poor scorch resistance of materials, affecting long-term continuous extrusion of rubber materials, etc., to achieve high electrical performance, Stable and reliable anti-scorch performance, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides an insulating material with anti-scorch properties, the preparation method of which is as follows:

[0044] Take by weighing the following materials in parts by mass: low-density polyethylene LDPE for ultra-clean cable material (molecular weight distribution is 5.6, melt index is 2.1g / min and volume resistivity 2 * 10 17Ω·cm) 100kg, the compound antioxidant is 4,4'-thiobis(6-tert-butyl-3-methylphenol) and antioxidant 168 according to 4:1 weighing 0.4kg, diperoxide Cumene and triallyl isocyanurate (4:1) 1.6kg, plasticizer (dimethyl phthalate) 0.08kg.

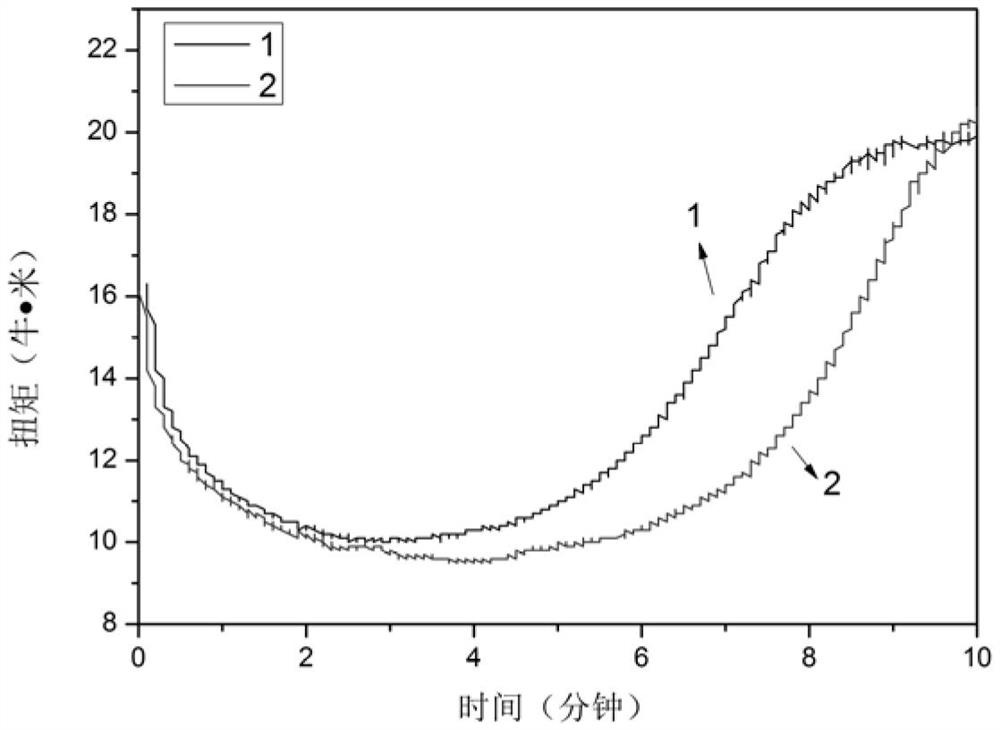

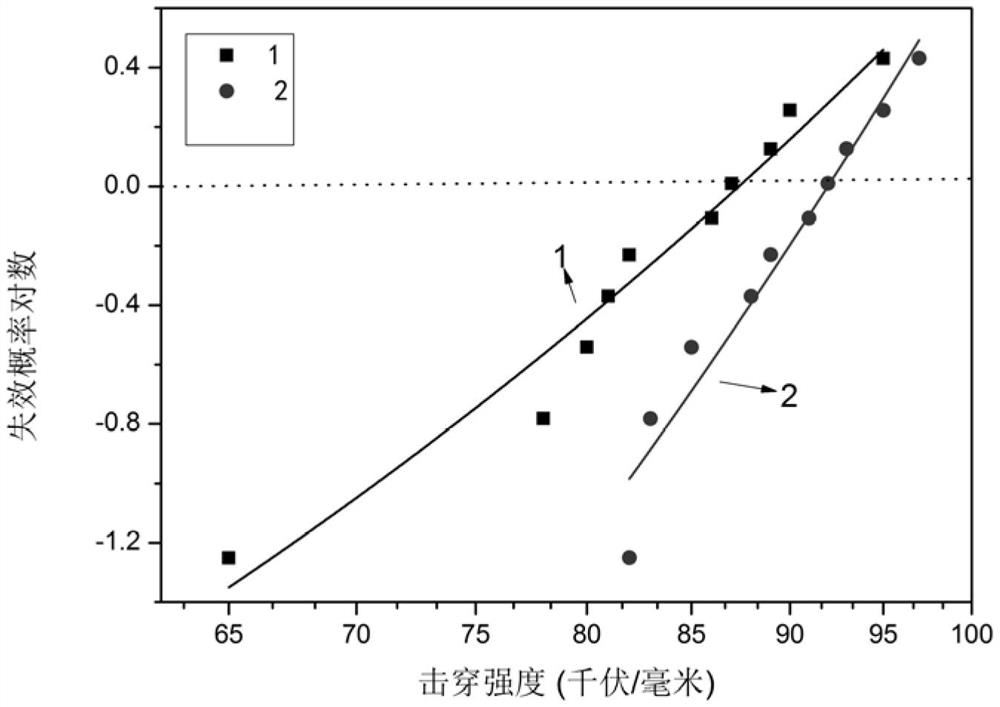

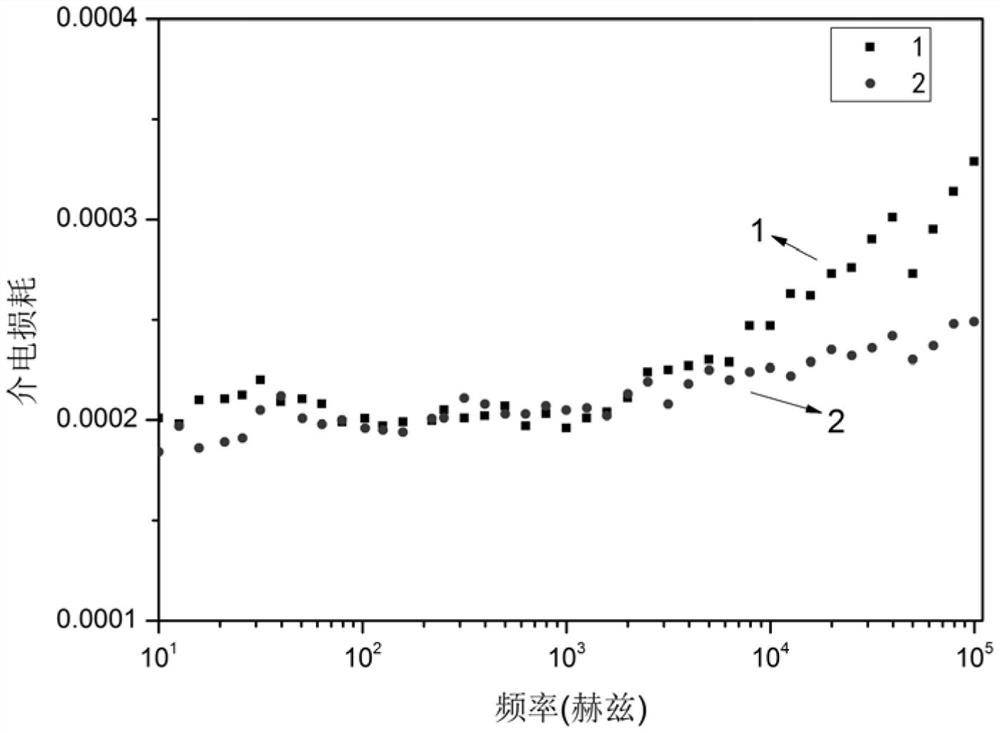

[0045] The two antioxidants are pre-mixed by high-speed stirring at 30°C and 150r / min; then the low-density polyethylene, antioxidant and plasticizer are sequentially added to the internal mixer at a speed of 60r / min and a temperature of 120 Melt and knead at ℃ for 40 minutes, after filtering impurities through the melt filtration system (500 mesh filter screen), the obtained material enters the s...

Embodiment 2

[0048] This embodiment provides an insulating material with anti-scorch properties, the preparation method of which is as follows:

[0049] Take by weighing the following materials in parts by mass: low-density polyethylene LDPE for ultra-clean cable material (molecular weight distribution is 5.6, melt index is 2.1g / min and volume resistivity 2 * 10 17 Ω·cm) 100kg, the compound antioxidant is 4,4'-thiobis(6-tert-butyl-3-methylphenol) and antioxidant 168 according to 4:1 weighing 0.8kg, diperoxide Cumene and triallyl isocyanurate 1.8kg (4:1), plasticizer (dimethyl phthalate) 0.08kg.

[0050] The two antioxidants are pre-mixed by high-speed stirring at 80°C and 150r / min; then the low-density polyethylene, compound antioxidant and plasticizer are added to the internal mixer in sequence at a speed of 60r / min Melt and knead for 40 minutes at a temperature of 120°C, filter impurities through a melt filtration system (500 mesh filter) and enter the single-screw melt, extrude from th...

Embodiment 3

[0053] This embodiment provides an insulating material with anti-scorch properties, the preparation method of which is as follows:

[0054] Take by weighing the following materials in parts by mass: low-density polyethylene LDPE for ultra-clean cable material (molecular weight distribution is 5.6, melt index is 2.1g / min and volume resistivity 2 * 10 17 Ω·cm) 100kg, compound antioxidant 4,4'-thiobis(6-tert-butyl-3-methylphenol) and antioxidant 168 weighed 1.5kg according to 4:1, diisoperoxide Propylene and triallyl isocyanurate 1.8kg (4:1), plasticizer (dimethyl phthalate) 0.08kg.

[0055] The two antioxidants are premixed by high-speed stirring at 30°C and 150r / min; then the premix, low-density polyethylene, antioxidant and plasticizer are sequentially added to the internal mixer at a speed of 60r Melting and kneading for 40 minutes at a temperature of 120°C. After filtering impurities through a melt filtration system (500 mesh filter), the resulting material enters the singl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com