Pipe body deviation rectifying device for glass fiber reinforced plastic mortar pipe production

A technology of glass fiber reinforced plastic sand inclusion and deviation correction device, which is applied in the conveyor control device, transportation and packaging, conveyor objects, etc., can solve the problems that the pipeline cannot be transported stably and safely, and is prone to deviation, so as to save labor costs and improve the application. Sexual, innovative design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

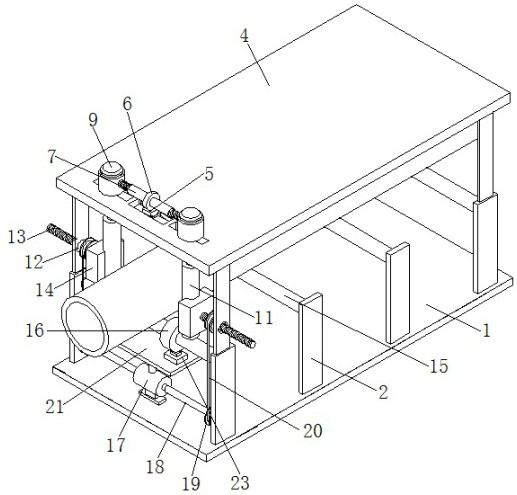

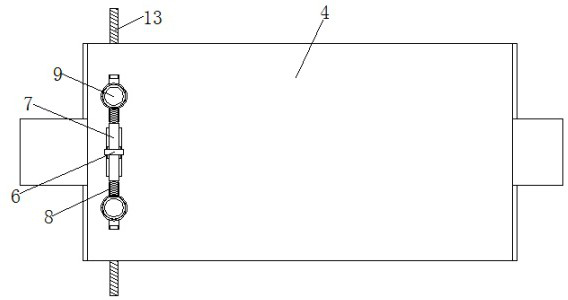

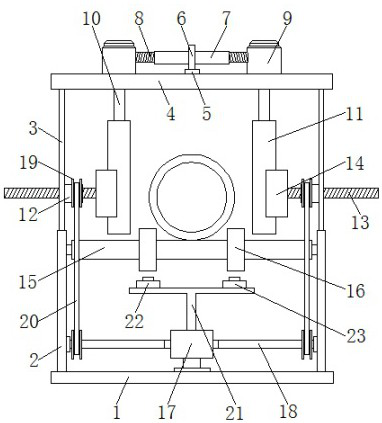

[0027] refer to Figure 1-3 : A pipe body correction device for the production of FRP sand-filled pipes, comprising a bottom plate 1, a plurality of first support plates 2 fixedly connected to the top of the bottom plate 1, a second support plate 3 fixedly connected to the top of the first support plate 2, and a second support plate 3 fixedly connected to the top of the bottom plate 1. The top of the support plate 3 is fixedly connected with a cover plate 4, the top of the cover plate 4 is slidingly connected with an adjustment mechanism, and the two ends of the adjustment mechanism are fixedly connected with a deviation correction assembly, and the sides of the two deviation correction assemblies are provided with a second support. The second threaded pipe 12 connected with the rotation of the plate 3, the inner thread of the second threaded pipe 12 is provided with a second screw rod 13, and an extruding plate 14 is fixedly connected between the two second screw rods 13. The...

Embodiment 2

[0033] refer to figure 1 , Figure 4-6 : A pipe body correction device for the production of FRP sand-filled pipes. The switch assembly includes a supporting plate 21 fixedly connected to the top of the biaxial motor 17. The left side of the top of the supporting plate 21 is fixedly connected with a clockwise drive switch 22. The supporting plate 21 The right side of the top of the top is fixedly connected with a counterclockwise drive switch 23, the driving mechanism includes a biaxial motor 17 fixedly connected with the bottom plate 1, the output shaft of the biaxial motor 17 is fixedly connected with a transmission shaft 18, the transmission shaft 18 and the second threaded pipe 12 The outer fixed sleeve of the belt pulley 19 is provided with a pulley 19, and the outer sleeve of the two pulleys 19 is provided with a belt 20; when the pipeline is offset, it will squeeze the air bag on the feed roller 15, and the air bag extrusion will protrude downward, so that The airbag w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com