Preparation method of anti-inflammatory and acne mark-removing hydrocolloid acne paste

A hydrocolloid and acne scar technology, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the core problems of acne healing, poor wound inflammation inhibition ability and wound healing ability, etc., to achieve improvement Skin self-healing ability, relieve striated muscle and smooth muscle spasm, and promote wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

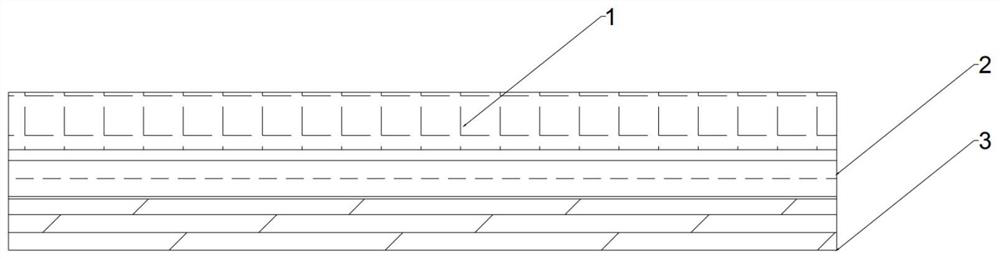

Image

Examples

preparation example Construction

[0028] A preparation method of anti-inflammatory and anti-acne printing hydrocolloid acne patch, comprising the following steps:

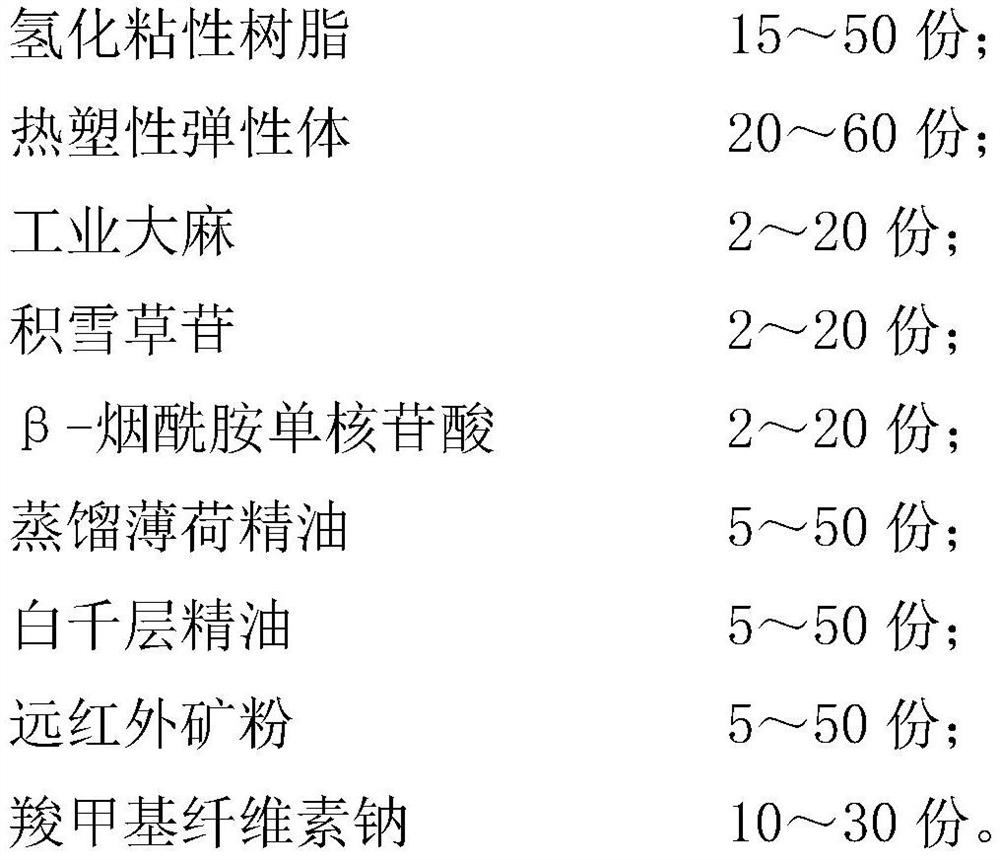

[0029] 1) Put 15-50 parts by weight of hydrogenated viscous resin and 20-60 parts by weight of thermoplastic elastomer into a mixer, heat at 130°C-150°C, stir, stir at 40-50 rpm to dissolve, and obtain component A;

[0030] 2) At a room temperature of 20°C-25°C, fully mix 2-20 parts by weight of industrial hemp, 2-20 parts by weight of asiaticoside, and 2-20 parts by weight of β-nicotinamide mononucleotide with a powder mixer. Stir to obtain component B;

[0031] 3) At a room temperature of 20°C-25°C, take 5-50 parts by weight of distilled peppermint essential oil and 5-50 parts by weight of melaleuca essential oil by stirring and stirring to obtain component C;

[0032] 4) Slowly add 5 to 50 parts by weight of far-infrared mineral powder and 10 to 30 parts by weight of sodium carboxymethylcellulose into component A obtained in step 1), and carry ...

Embodiment 1

[0045] 1) Put 30 kg of hydrogenated viscous resin and 45 kg of thermoplastic elastomer into a mixer, heat at 130°C-150°C, stir, stir and dissolve at 40-50 rpm, and obtain component A;

[0046] 2) Fully stir 5 kg of industrial hemp, 5 kg of asiaticoside, and 4 kg of β-nicotinamide mononucleotide with a powder mixer at a room temperature of 20°C-25°C to obtain component B;

[0047] 3) At a room temperature of 20°C-25°C, take 8 kg of distilled peppermint essential oil and 7 kg of melaleuca essential oil through stirring and stirring to obtain component C;

[0048] 4) Slowly add 35 kg of far-infrared mineral powder and 15 kg of sodium carboxymethyl cellulose to the component A obtained in step 1), and carry out vacuum constant temperature stirring at a stirring speed of 40-50 rpm and a temperature of 120°C - 130°C, 60-90min, to obtain component D; stir and dissolve component B and component C in a constant temperature mixer at 100°C until no solid precipitates are precipitated; slow...

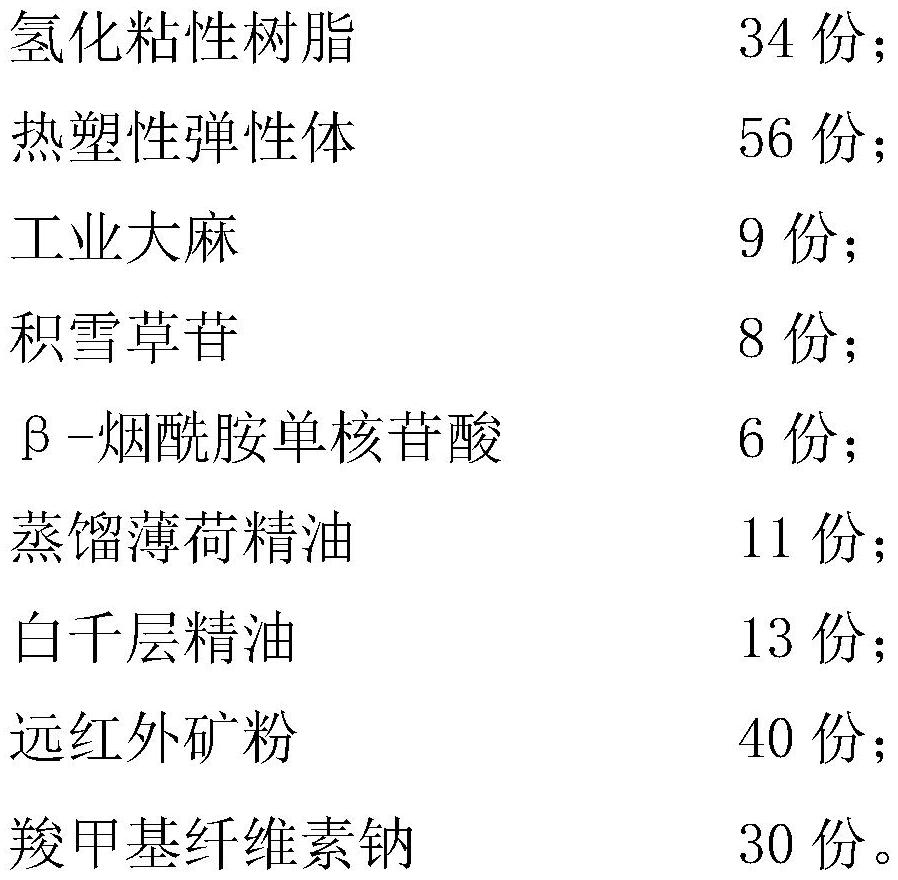

Embodiment 2

[0055] 1) Put 17 kg of hydrogenated viscous resin and 28 kg of thermoplastic elastomer into a mixer, heat at 130°C-150°C, stir, stir and dissolve at 40-50 rpm, and obtain component A;

[0056] 2) Fully stir 2 kg of industrial hemp, 2 kg of asiaticoside, and 2 kg of β-nicotinamide mononucleotide with a powder mixer at a room temperature of 20°C-25°C to obtain component B;

[0057] 3) At a room temperature of 20°C-25°C, take 5 kg of distilled peppermint essential oil and 5 kg of melaleuca essential oil through stirring and stirring to obtain component C;

[0058] 4) Slowly add 18 kg of far-infrared mineral powder and 20 kg of sodium carboxymethyl cellulose to the component A obtained in step 1), and carry out vacuum constant temperature stirring at a stirring speed of 40-50 rpm and a temperature of 120°C - 130°C, 60-90min, to obtain component D; stir and dissolve component B and component C in a constant temperature mixer at 100°C until no solid precipitates are precipitated; sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com