A kind of fruit core crisp automatic production system and its production process

A technology of production process and production system, which is applied in the automatic production system of fruit core crisps and its production process, can solve the problems of low heat energy utilization rate, poor baking effect, and affecting the quality of fruit core crisps, so as to improve the utilization rate and ensure Roast quality, improved mixing and efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

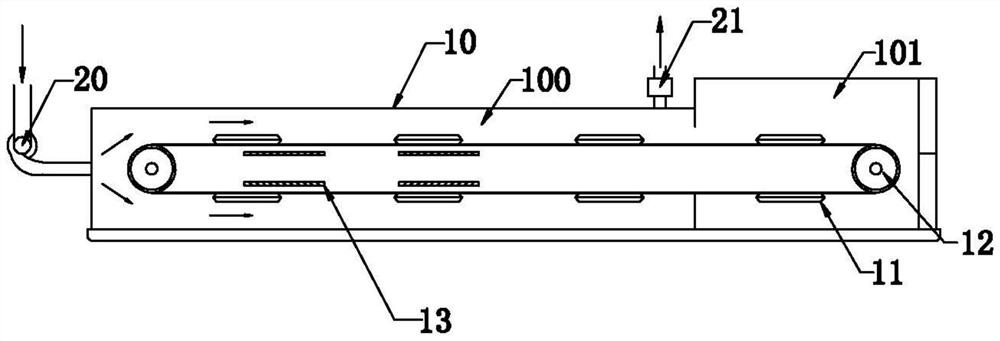

[0048] Such as figure 1 As shown, the present invention discloses a kind of fruit core crisp automatic production system, comprising:

[0049] Baking oven 10, which has at least one baking area 100 and at least one retrieving area 101;

[0050] Mold 11, for placing the baked object;

[0051] An endless conveyor 12, the endless conveyor 12 can transport the mold 11 to circulate between the baking area 100 and the picking area 101;

[0052] The heating part 13 is arranged in the baking area 100 and is used to heat the baking area 100;

[0053] It is characterized by:

[0054] At least one air inlet portion 20 and an air outlet portion 21 are provided in the baking area 100;

[0055] The air intake part 20 has an air intake end, and the air intake end is arranged at any place in the roasting area 100 for introducing outside air and supplying the air into the roasting area 100;

[0056] The air outlet part 21 has an air outlet end, and the air outlet end is arranged on the ba...

Embodiment 2

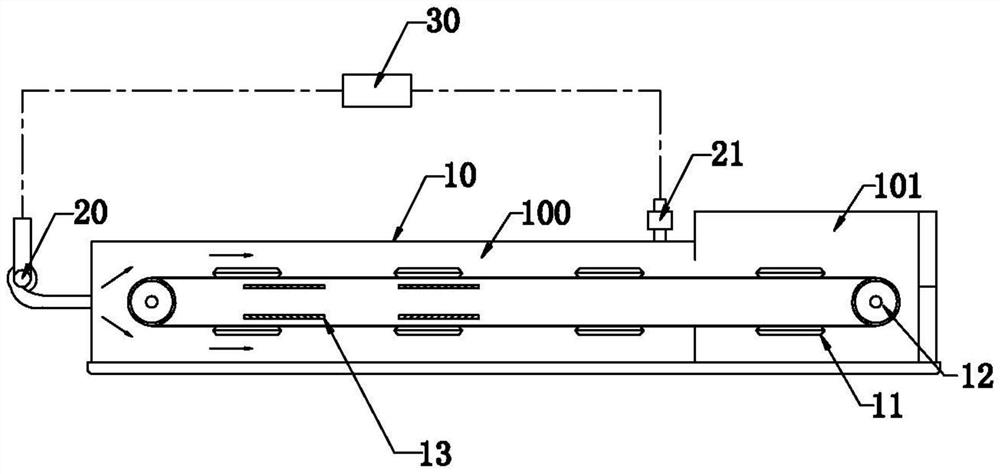

[0066] Embodiment 2, the difference with embodiment 1 is that

[0067] Such as Figure 2-3 As shown, in the specific embodiment of the present invention, at least one heat energy recovery device 30 is also included, and the heat energy recovery device 30 is used to recover the hot gas discharged from the air outlet part 21 and send the hot gas to the air inlet part 20 .

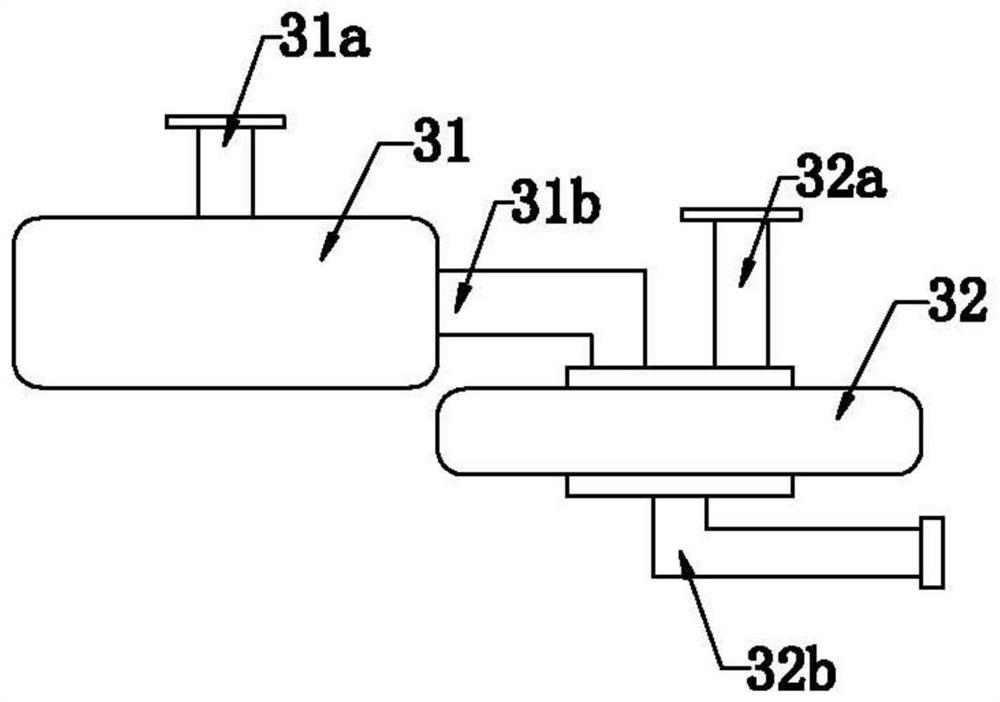

[0068] In a specific embodiment of the present invention, the heat energy recovery device 30 includes at least a first air intake unit 31, a second air intake unit 32, and a gas source for driving gas flow, wherein the first air intake unit 31 at least It has a first air inlet 31a and a first air outlet 31b, the second air inlet unit 32 has at least a second air inlet 32a and a second air outlet 32b, and the second air outlet 32b forms the inlet The gas end, wherein the first air inlet 31a and the second air inlet 32a respectively allow outside air and hot air to enter, and after mixing in the second air inl...

Embodiment 3

[0072] Embodiment 3, the difference with embodiment 2 is that

[0073] Such as Figure 4-7 As shown, in a specific embodiment of the present invention, the first air intake unit 31 includes a first body 310 with a first inner cavity 311, and the first air outlet is provided on the side wall of the first body 310 31a, and a first chamber 3101, a second chamber 3102 and a third chamber 3103 distributed longitudinally in the first body 310, the third chamber 3103 is filled with part of the liquid medium 3104, and A heater 3105 may be provided in the third chamber 3103, an air outlet pipe 3106 is provided in the first chamber 3101 and on the second chamber 3102, and the other end of the air outlet pipe 3106 is connected to the first air outlet 31a, the first chamber 3101 is provided with a container tube 3107 with both ends open, and a medium body 3108 is provided in the container tube 3107, the container tube 3107 is placed obliquely, and the bottom is in line with the first cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com