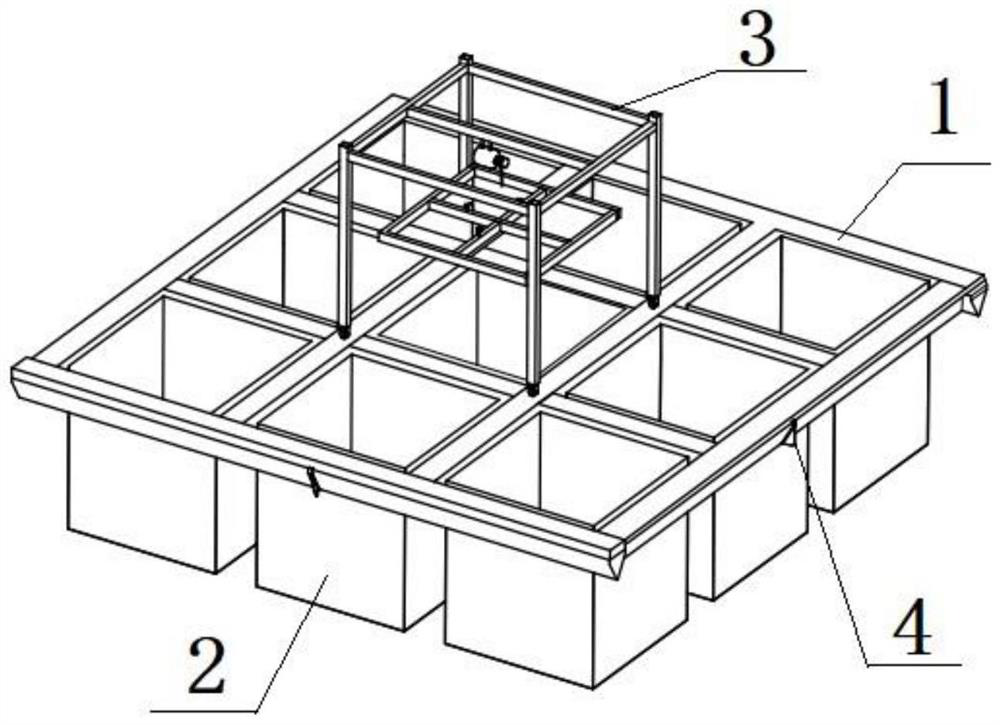

Netting and net cage system used for mariculture

A technology for nets and cages, applied in application, fish farming, climate change adaptation, etc., can solve the problems of inconvenient manual operation of nets, easy damage of connecting parts, and high density of copper alloys, so as to save the cost of nets, The effect of reducing the number of parts and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

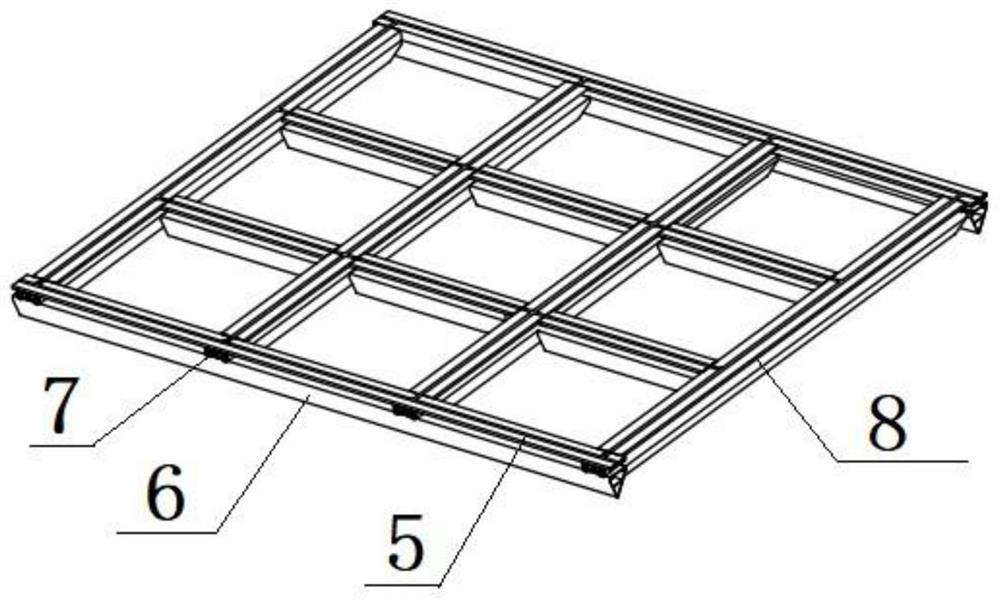

[0035] A plurality of floating pipes are cross-connected to form 9 grids, that is, 9 breeding areas, each of which is a square with a side length of 4m. The floating tube is used as a hollow profile with a pentagonal cross-section. The cross-section is left-right symmetrical. The five angles of the cross-section are 60°, 150°, 90°, 90°, and 150°. The angle of the cross-section angle of 60° is arranged downward. , the length of the two vertical faces of the section is 100mm, the length of the horizontal side on the upper side of the section is 600mm, and the height of the section is 600mm. There are reinforcing ribs connecting the two slopes inside the section, and a T-shaped groove on the upper part of the section. The connection plate is made into a rectangular cavity profile with a section width of 560mm and a section height of 150mm. There are several inclined reinforcing ribs inside the section, and a T-shaped block is provided at the lower part of the section. The T-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com