A kind of cobalt-free nickel-free cathode material, its preparation method and battery

A nickel positive electrode and battery technology, which is applied to cobalt-free and nickel-free positive electrode materials, its preparation method and the field of batteries, can solve problems such as environmental hazards and battery cost constraints, and achieve the effects of promoting production, improving cycle performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

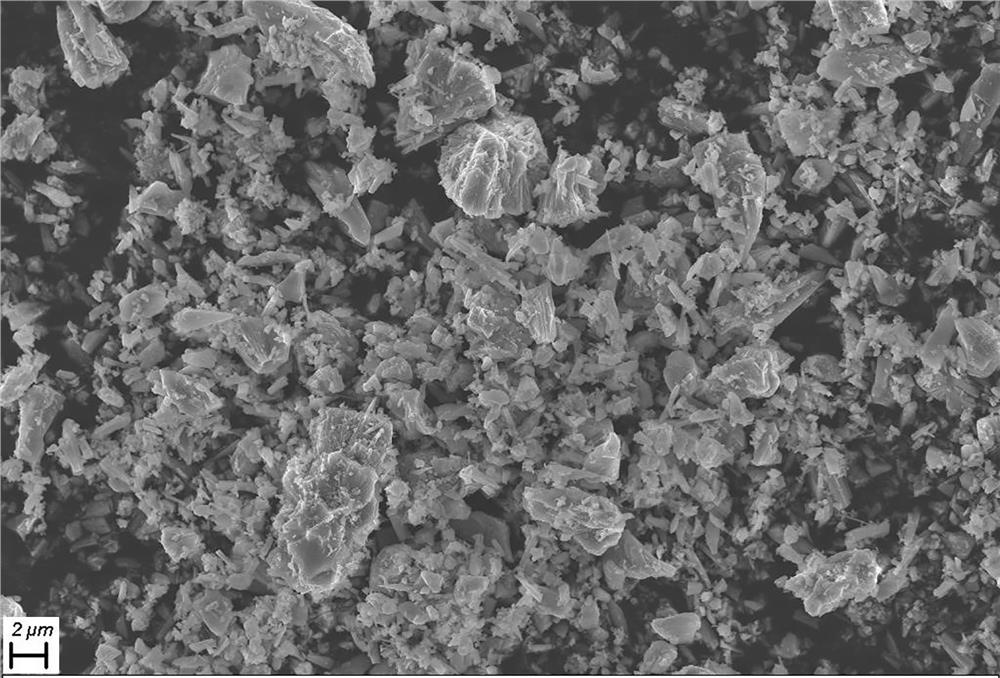

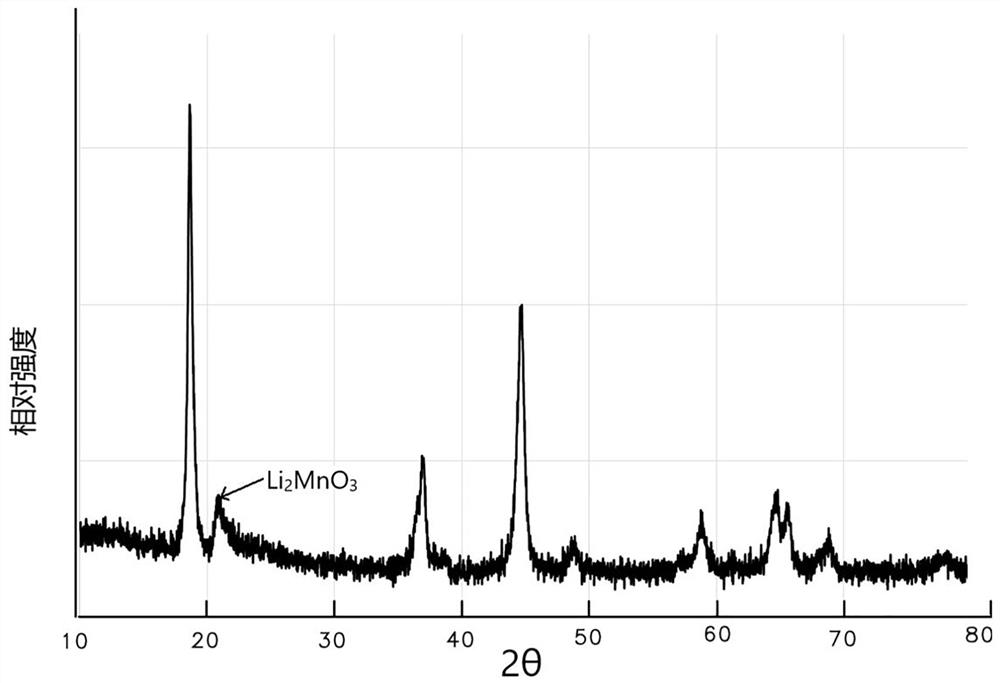

[0051] This embodiment provides a method for preparing a cobalt-free and nickel-free positive electrode material. The preparation method specifically includes the following steps:

[0052] (I) Mix lithium carbonate, sodium carbonate and manganese carbonate, the molar ratio of lithium element, sodium element and manganese element is 0.25:1:0.75, and heat at 750°C for 10 hours in an air atmosphere to prepare the cobalt-free and nickel-free Matrix material, the general formula is NaLi 0.25 mn 0.75 o 2 , the air flow rate is 7.5L / min;

[0053] (II) Mix the cobalt-free and nickel-free base material prepared in step (I), lithium carbonate and MnO to obtain a mixture. The molar ratio of lithium element to manganese element in the mixture is 1.2:1, and conduct a melting reaction at 600°C for 6h, Add water to the reacted material, stir and wash for 10 minutes, the quality of the added water is twice the mass of the material, and dry after washing;

[0054] (Ⅲ) After drying, the cob...

Embodiment 2

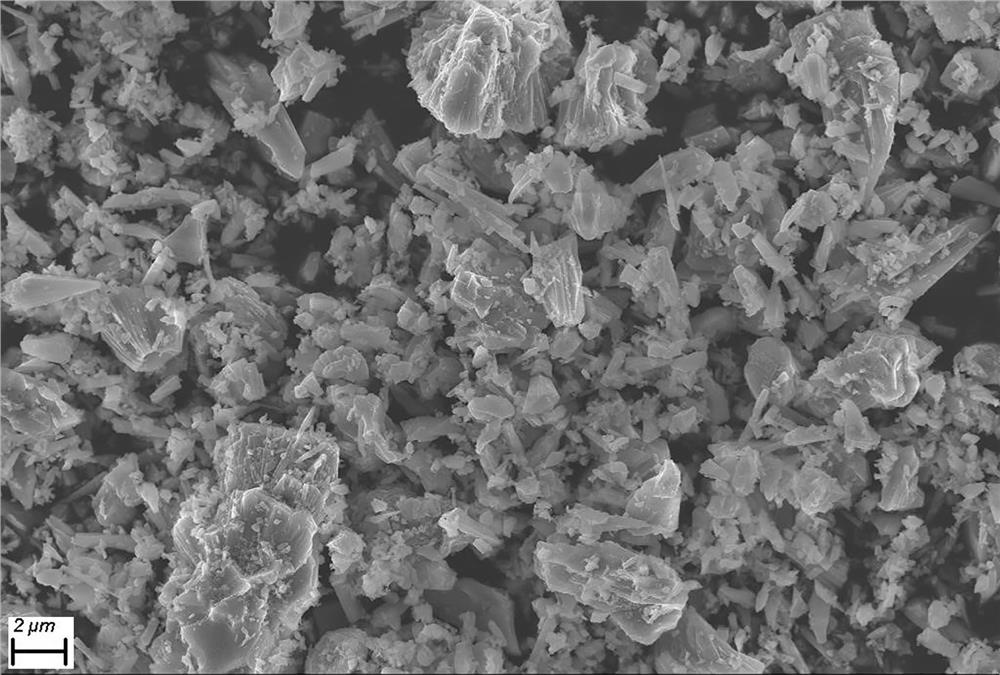

[0057] This embodiment provides a method for preparing a cobalt-free and nickel-free positive electrode material. The preparation method specifically includes the following steps:

[0058] (I) Mix lithium hydroxide, sodium acetate and manganese monoxide, the molar ratio of lithium, sodium and manganese is 0.25:1:0.75, and heat at 500°C for 12 hours in an air atmosphere to prepare the cobalt-free Nickel-free matrix material, the general formula is NaLi 0.25 mn 0.75 o 2, the air flow rate is 5L / min;

[0059] (II) The cobalt-free and nickel-free base material prepared in step (I), lithium hydroxide and Mn 3 o 4 Mix to obtain a mixture, the molar ratio of lithium element to manganese element in the mixture is 0.9:1, conduct a melting reaction at 400°C for 8 hours, add water to the reacted material and stir and wash for 10 minutes, the quality of the added water is twice the mass of the material , dry after washing;

[0060] (Ⅲ) After drying, the cobalt-free and nickel-free c...

Embodiment 3

[0063] This embodiment provides a method for preparing a cobalt-free and nickel-free positive electrode material. The preparation method specifically includes the following steps:

[0064] (I) Mix lithium chloride, sodium chloride and manganese trioxide, the molar ratio of lithium element, sodium element and manganese element is 0.25:1:0.75, and heat at 800°C for 8 hours in an air atmosphere to prepare the described Cobalt-free and nickel-free matrix material, the general formula is NaLi 0.25 mn 0.75 o 2 , the air flow rate is 10L / min;

[0065] (II) The cobalt-free and nickel-free base material prepared in step (I), lithium chloride and MnCO 3 Mix to obtain a mixture, the molar ratio of lithium element to manganese element in the mixture is 1.5:1, conduct a melting reaction at 800°C for 4 hours, add water to the reacted material and stir and wash it for 10 minutes, the mass of water added is twice the mass of the material , dry after washing;

[0066] (Ⅲ) After drying, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com