High-capacity fast charging battery with infiltrating grid type electrode

A high-capacity, grid-type technology, applied in the direction of active material electrodes, electrode carriers/collectors, non-aqueous electrolyte batteries, etc., can solve the problems of environmental pollution of battery electrodes, rapid battery aging, and shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with embodiment:

[0043] Example:

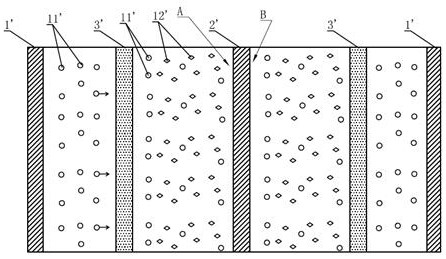

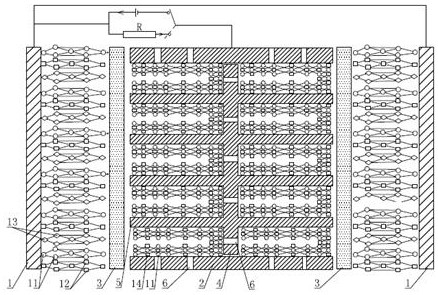

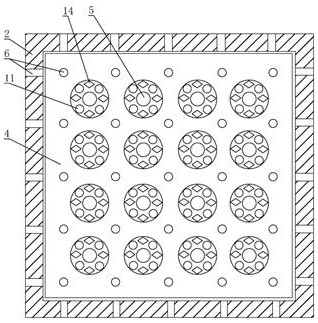

[0044] Such as Figure 1~Figure 4 , the present invention has a high-capacity fast-charge battery with a wettable grid electrode, the high-capacity battery includes a positive electrode, a negative electrode, an insulating separator 3 arranged between the positive electrode and the negative electrode, and an electrolyte, the Electrolyte is filled between the positive electrode and the insulating separator, and the negative electrode and the insulating separator, the positive electrode includes a positive electrode current collector 1, a positive electrode coating, the positive electrode current collector is aluminum AL, and the positive electrode coating is LiCoO2, 11 is Li, 12 is Co, 13 is O, 14 is Si;

[0045] The negative pole is a wettable grid electrode, and the negative pole includes a negative electrode current collecting bridge 2, a grid plate 4, and a cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com