A kind of mxene/nickel phosphate electrode material and its preparation method and application

An electrode material, nickel phosphate technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of low specific capacity, stability or specific capacitance difference, specific capacitance and stability improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides the preparation method of the MXene / nickel phosphate electrode material described in the above technical solution, comprising the following steps:

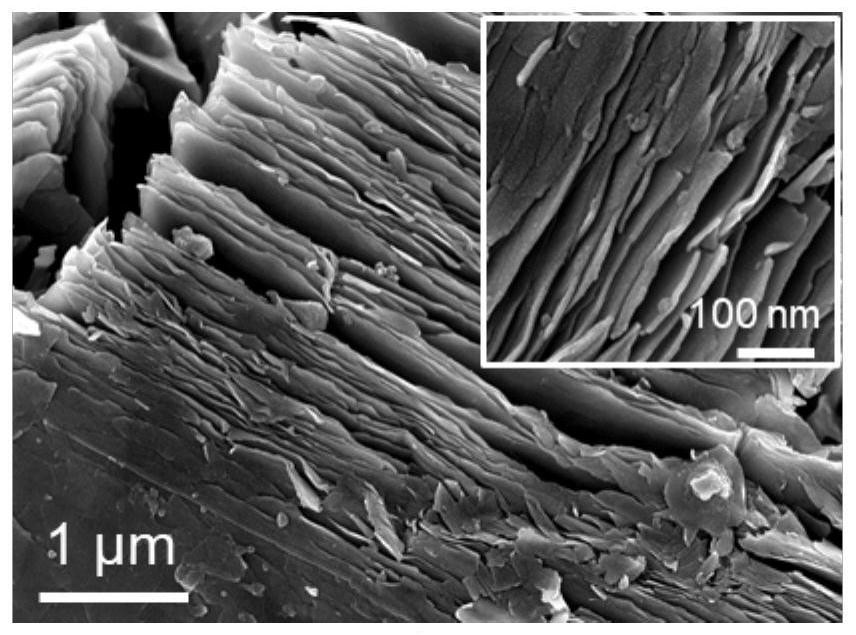

[0048] (1) mixing the MAX phase material with metal fluoride salt and hydrochloric acid for a first etching reaction to obtain an intermediate; mixing the intermediate with hydrofluoric acid for a second etching reaction to obtain an MXene nanosheet;

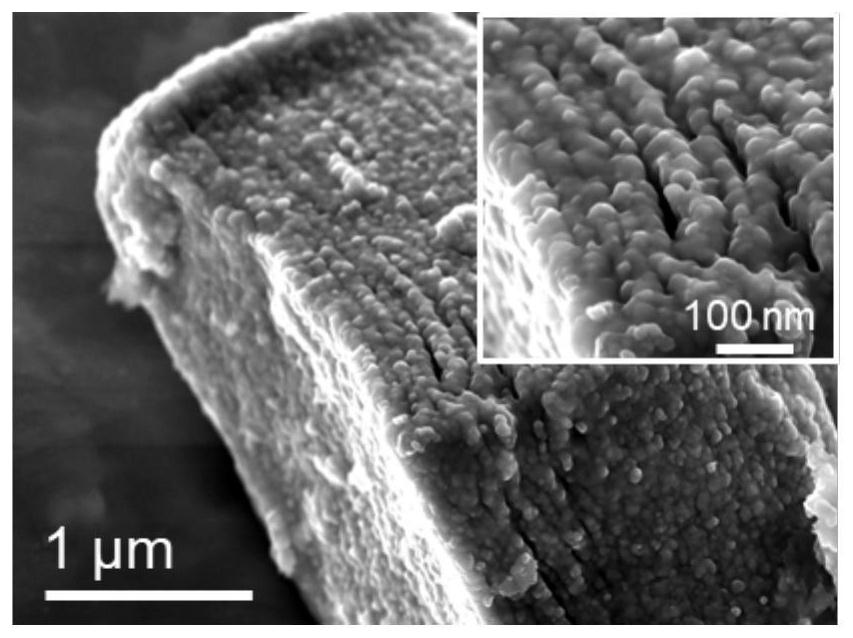

[0049] (2) mixing nickel nitrate hexahydrate, terephthalic acid, an organic solvent and the MXene nanosheet obtained in the step (1), and performing a solvothermal reaction to obtain MXene-MOF;

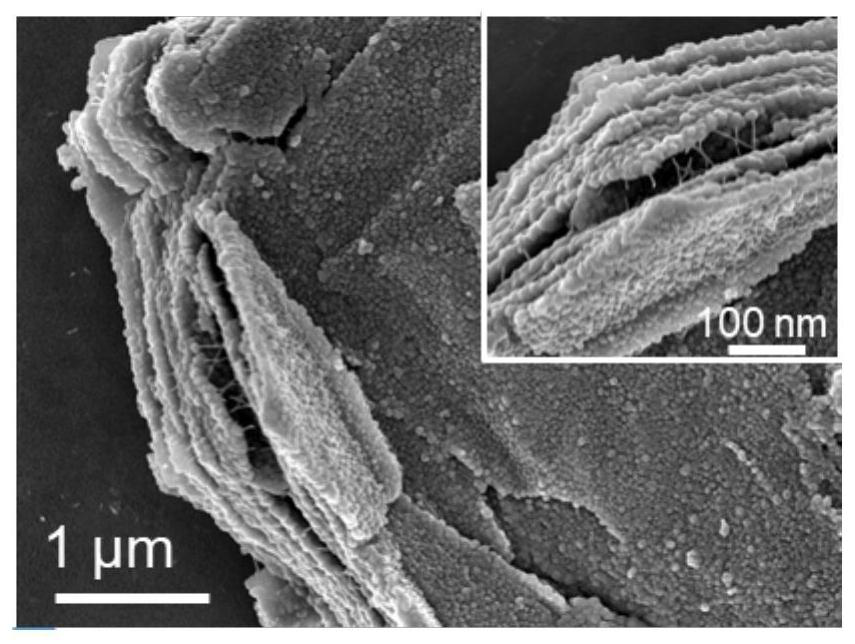

[0050] (3) mixing the MXene-MOF obtained in the step (2) with a potassium dihydrogen phosphate solution, and performing an ion exchange reaction to obtain an MXene / nickel phosphate electrode material.

[0051] In the present invention, the MAX phase material is mixed with the metal fluoride salt and hydrochloric acid to carry out the first etching ...

Embodiment 1

[0093] (1) 3g Ti 2 AlC 3 Mixed with 1.98g LiF and 50mL concentrated hydrochloric acid with a concentration of 4mol / L, the first etching reaction was carried out under stirring at 40 ° C for 24h, and the intermediate was obtained by washing and centrifuging with deionized water; the mass fraction of the intermediate and 50mL was 45% hydrofluoric acid was mixed and kept stirring at 50°C for 24 hours to carry out the second etching reaction. Then, deionized water and absolute ethanol were used to wash and centrifuge to obtain a black precipitate, and MXene nanosheets were obtained after lyophilization for 12 hours. Among them, MAX phase material (Ti 2 AlC 3 ), the mass ratio of metal fluoride (LiF) and hydrochloric acid is 3:1.98:50, Ti 2 AlC 3 The mass ratio to LiF is 1:0.66.

[0094] (2) Mix 0.5 g of nickel nitrate hexahydrate, 0.15 g of terephthalic acid and 150 mL of DMF to obtain a transparent solution, and then disperse 0.05 g of the MXene nanosheets prepared in step (...

Embodiment 2

[0112] (1) Put 2.5g V 2 AlC with 1.5g NH 4 F was mixed with 40 mL of concentrated hydrochloric acid with a concentration of 4 mol / L, and the first etching reaction was carried out under stirring at 40 °C for 24 h. The intermediate was obtained by washing and centrifuging with deionized water; the intermediate was mixed with 40 mL of 35% Mix with hydrofluoric acid, keep stirring at 40°C for 32h, carry out the second etching reaction, then use deionized water and absolute ethanol to wash and centrifuge to obtain black precipitate, and freeze-dry for 15h to obtain MXene nanosheets. Among them, MAX phase material (V 2 AlC), metal fluoride salts (NH 4 The mass ratio of F) and hydrochloric acid is 2.5:1.5:40, V 2 AlC and NH 4 The mass ratio of F is 5:3.

[0113] (2) Mix 0.5 g of nickel nitrate hexahydrate, 0.2 g of terephthalic acid and 250 mL of DMF to obtain a transparent solution, and then disperse 0.05 g of the MXene nanosheets prepared in step (1) in the transparent soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com