Acoustic parameter measuring device, method and system

An acoustic parameter, measuring device technology, applied in measuring devices, scientific instruments, material analysis using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of poor measurement accuracy, inability to fix the shape of the film, and troublesome production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

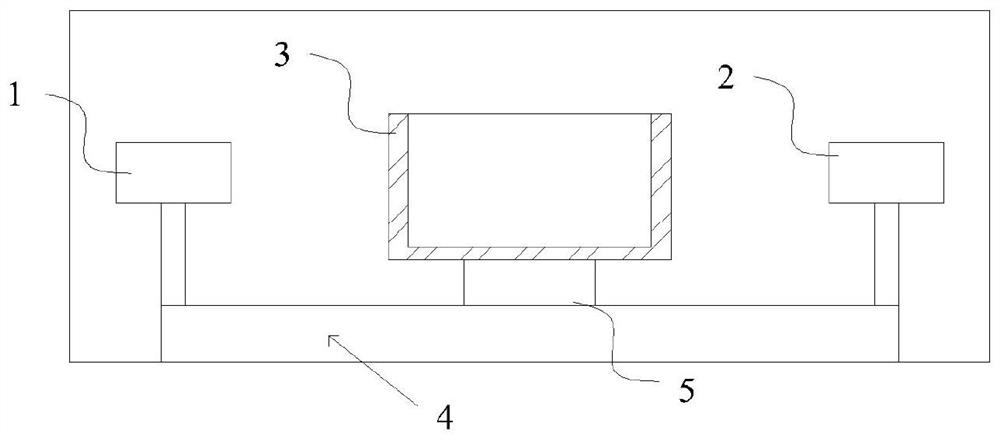

[0041] Such as Figure 1-2 As shown, the present embodiment provides an acoustic parameter measuring device, including an ultrasonic transmitting mechanism 1 and an ultrasonic receiving mechanism 2; there is a space with a fixed distance between the ultrasonic transmitting mechanism 1 and the ultrasonic receiving mechanism 2; it also includes: a sample container 3, A wall surface perpendicular to the plane wave acoustic beam path is provided, and at least two container parts with different inner cavity thicknesses are provided; there is relative movement between the sample container 3 and the plane wave acoustic beam path, which is used to change the direction of the sample container 3 in the plane wave acoustic beam path direction Among them, before and after the relative movement, the wall surface of the sample container passed by the plane wave sound beam path is perpendicular to the plane wave sound beam path, and the sum of the wall thicknesses of the sample container 3 in...

Embodiment 2

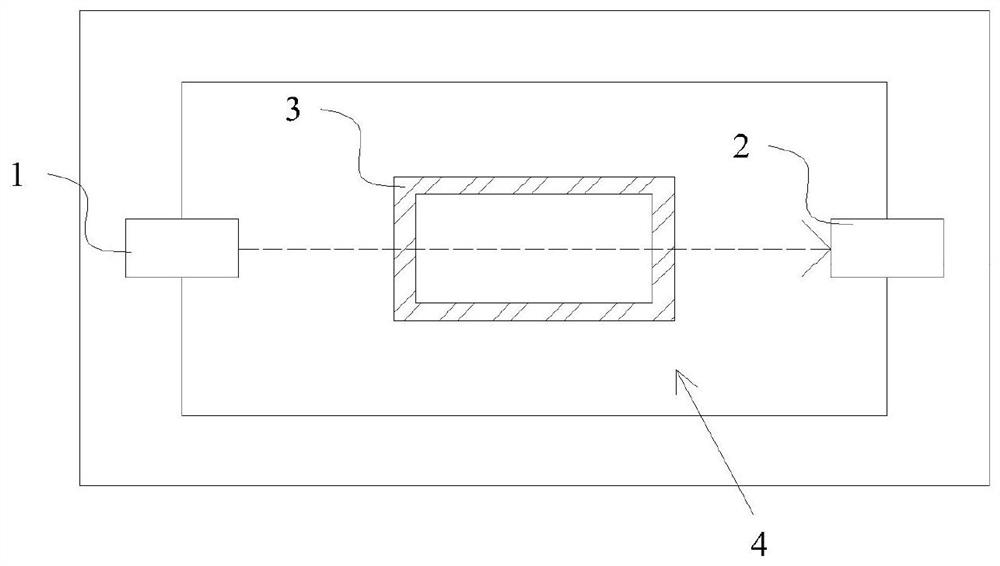

[0052] Such as Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 is that the ultrasonic transmitting mechanism 1 and the ultrasonic receiving mechanism 2 maintain a fixed distance to perform synchronous movement, while the sample container 3 remains stationary.

[0053] The moving device 5 is a turntable, and it is set to deflect 90° around its central axis each time it rotates. Two brackets are arranged on the surface circumference of the turntable, and the connecting line of the two brackets passes through the central axis of the turntable to connect to the ultrasonic emitting mechanism respectively. 1 and ultrasonic receiving mechanism 2. The sample container 3 is arranged directly above the center of the turntable through the positioning mechanism 4, and the central axis of the turntable passes through the geometric center of the bottom side of the sample container 3, so that the plane wave sound beam path between the ultrasonic transmitting mec...

Embodiment 3

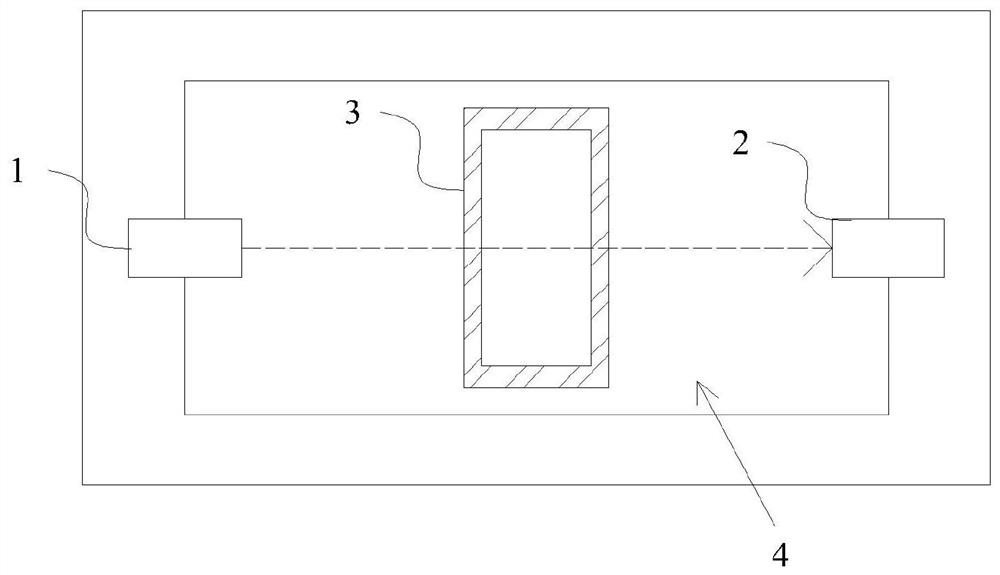

[0055] Such as Figure 5-6 As shown, the difference between this embodiment and Embodiment 1 lies in the shape and movement mode of the sample container 3 . The horizontal section of the sample container 3 in this embodiment is in a "convex" shape, and the thickness of the pulse passing through the sample container 3 is changed by means of translation.

[0056] The ultrasonic transmitting mechanism 1 and the ultrasonic receiving mechanism 2 are arranged on the positioning mechanism 4, and the surface of the center position of the positioning mechanism 4 is provided with two parallel guide rails to guide the moving device 5 to move back and forth. The moving device 5 is two moving brackets, one end of the two moving brackets is respectively connected to two guide rails, and the other end is fixed to the bottom of the sample container 3, and the sample container 3 is driven by the moving device 5 to move forward and backward, and the plane wave sound beam The path is perpendicu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com