Wall surface hardness detection device with anti-wear mechanism

A detection device and anti-wear technology, which can be used in measuring devices, testing material hardness, and cleaning methods using tools, etc., and can solve problems such as wall sag wall thickness, rebound tester and wall offset, affecting data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

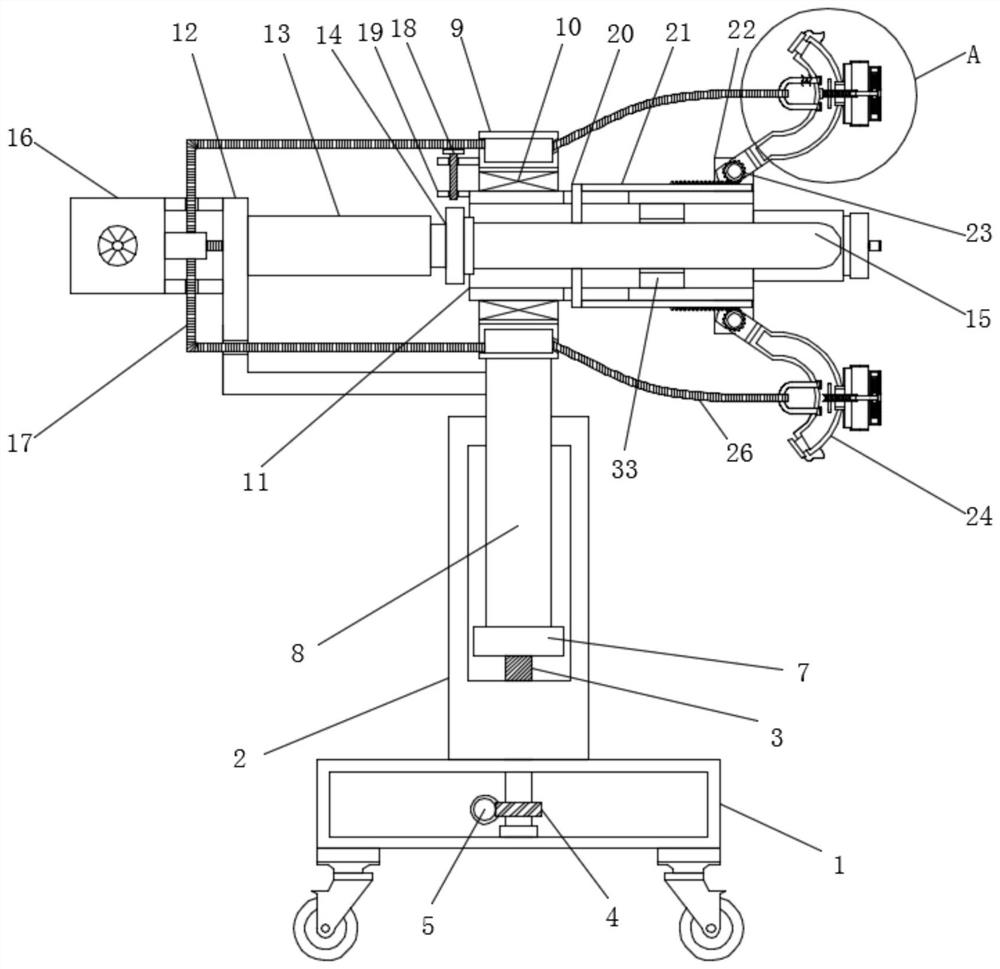

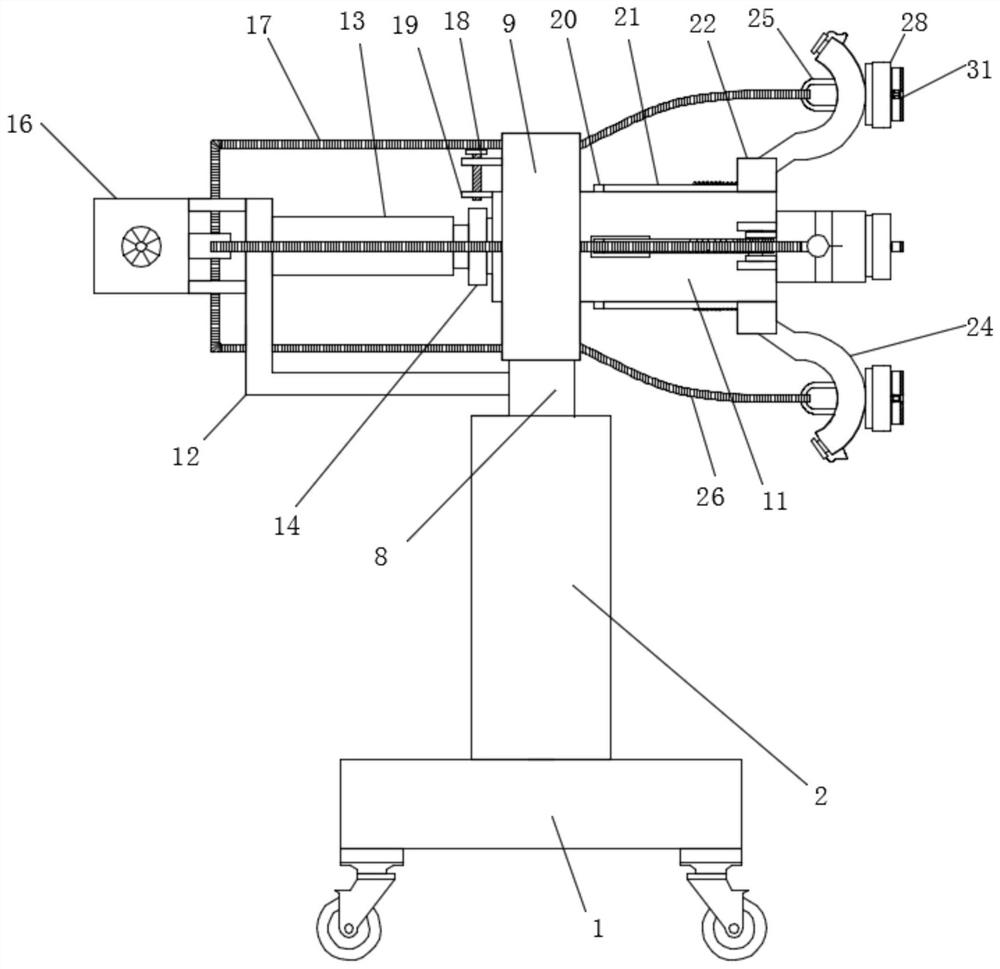

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0030] refer to Figure 1-6 , a wall hardness testing device with an anti-wear mechanism, comprising a bottom plate 1, the interior of the bottom plate 1 is provided with a cavity, and the four corners of the bottom end of the bottom plate 1 are equipped with moving wheels, and the moving wheels have a brake function. The device can be moved as needed, which increases the convenience of use.

[0031] The front and rear sides of the top of the bottom plate 1 are vertically fixed with vertical plates 2, and the opposite sides of the two vertical plates 2 are vertically provided with mounting grooves, and the inside of the mounting grooves is vertically movable. The bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com