Optical fiber strength testing method

A test method and optical fiber technology, applied in the direction of strength characteristics, the use of stable tension/pressure test material strength, measuring devices, etc., can solve problems such as easy loosening, insufficient fixing effect of optical fiber ends, and affecting test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

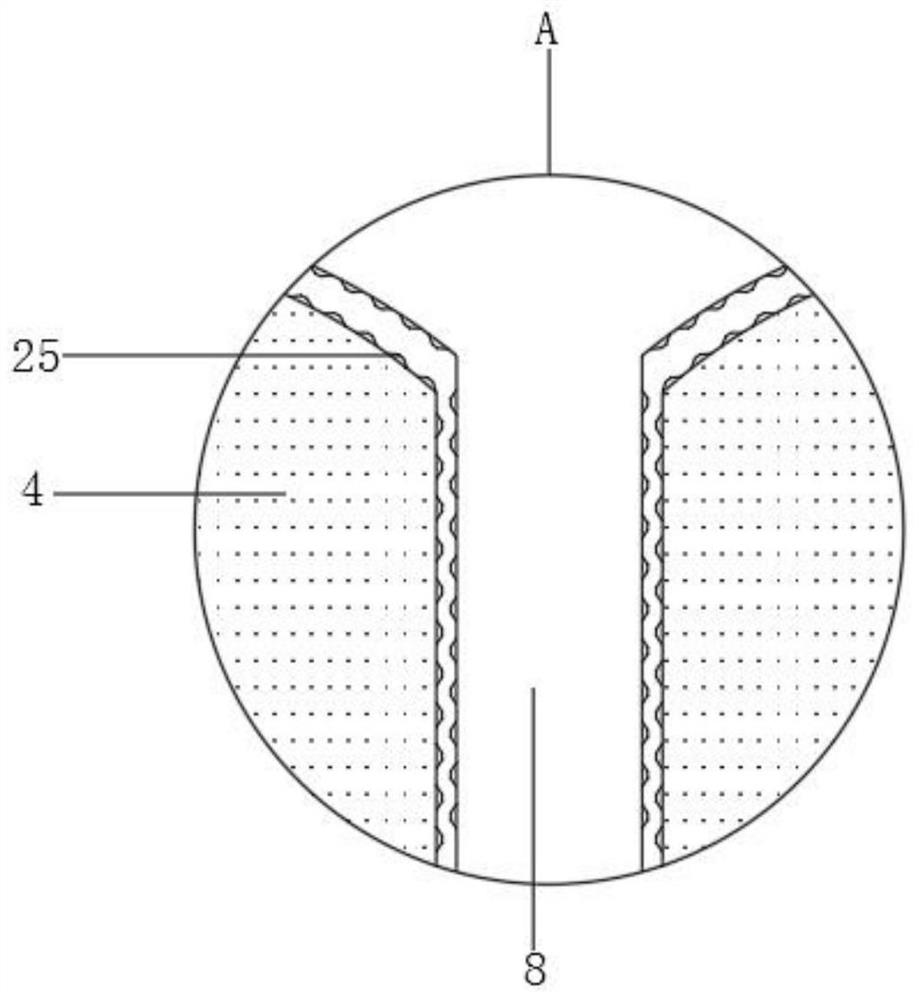

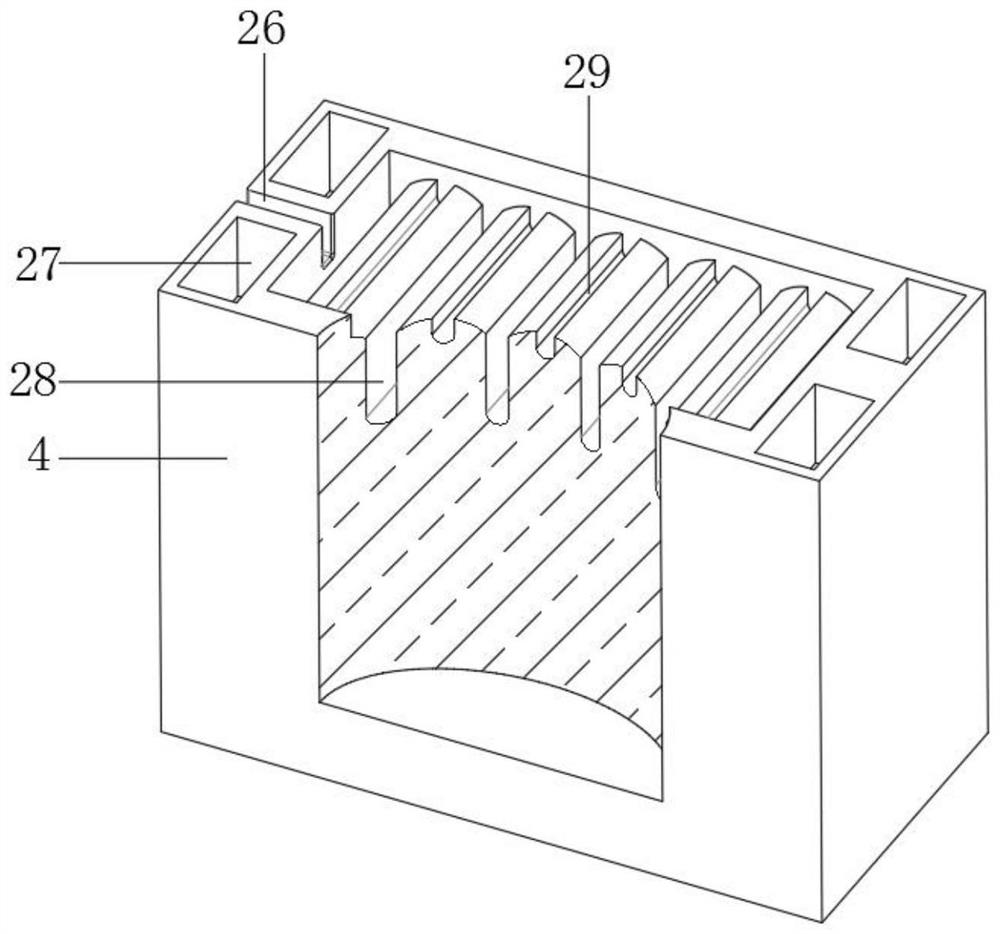

[0032] refer to Figure 1-6, an optical fiber testing device for strength, comprising a bottom plate 1 with four corners of the outer wall of the bottom welded with legs, side plates 2 are welded on both sides of the outer wall of the bottom plate 1, and the same platform is welded on the opposite side of the outer wall of the side plate 2 23, and the middle end of the platen 23 is fixedly installed with a limit end plate 36, and the two ends of the limit end plate 36 are respectively slidably connected with a fixed end block 15 and a pull block 4, and the top ends of the fixed end block 15 and the pull block 4 are both Equidistantly distributed arc bottom notches 28 and arc bottom short grooves 29 are provided, the arc bottom notches 28 and arc bottom short grooves 29 are alternately distributed, and the tops of the fixed end block 15 and the pulling block 4 are clamped with pressing blocks 13, and the bottom outer wall of the briquetting block 13 is respectively provided wit...

Embodiment 2

[0042] This embodiment discloses a method for testing the strength of an optical fiber, which includes the following steps: the operator places appropriate lengths of the two ends of the optical fiber to be tested on the fixed end block 15 and the top of the pulling block 4 respectively, and puts them into the corresponding pressing block 13, use the arc bottom socket 8 and the short pin 14 to match the arc bottom notch 28 and the arc bottom short groove 29 respectively, and fix the two ends of the optical fiber; The transmission effect of the tooth 19 and the driven tapered tooth 18 drives the threaded column rod 24 to rotate, so that the driving connecting plate 3 is used to push the pulling block 4, so that the optical fiber tends to be stretched straight; then, the operator controls and starts the electric telescopic rod 34 , push the cooling semi-copper tube 35 to close, and cooperate with the temperature sensor 11, use the semiconductor refrigerator 33 to keep the optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com