Novel portable wire harness connector sealing performance testing equipment

A technology for testing equipment and connectors, which is applied in the field of new portable wiring harness connector tightness testing equipment, can solve problems such as the inability to detect the wiring harness, the detection method being difficult to perform a wide range of detection, and the absence of unsealed joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

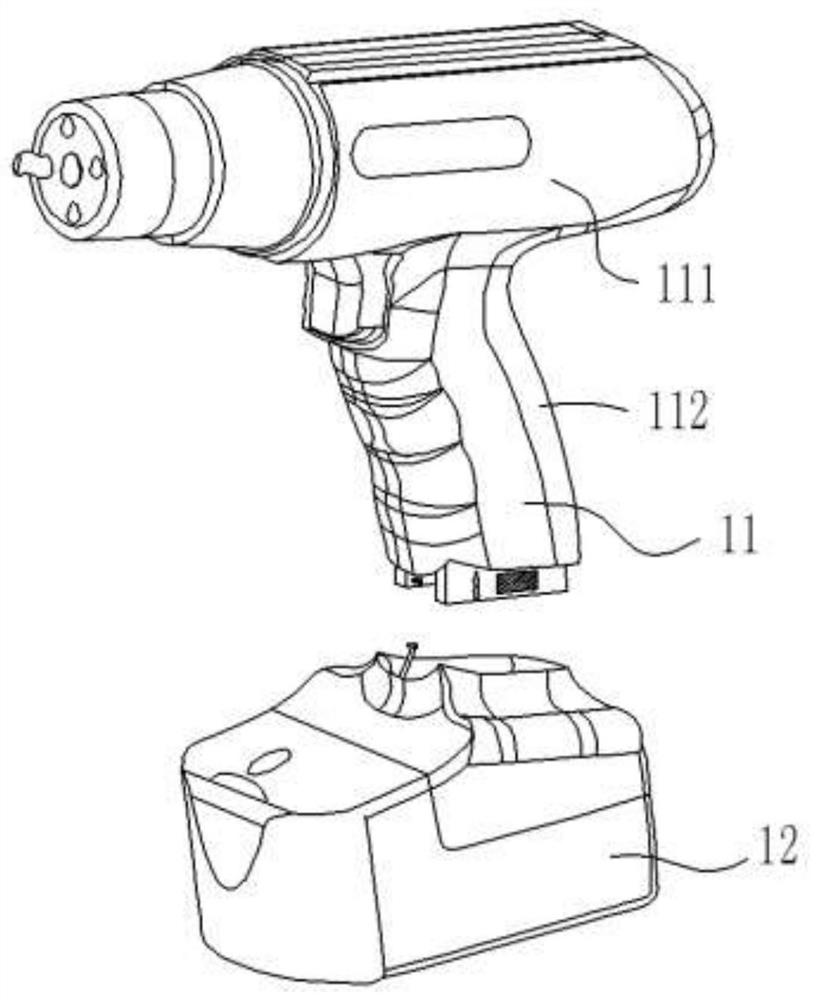

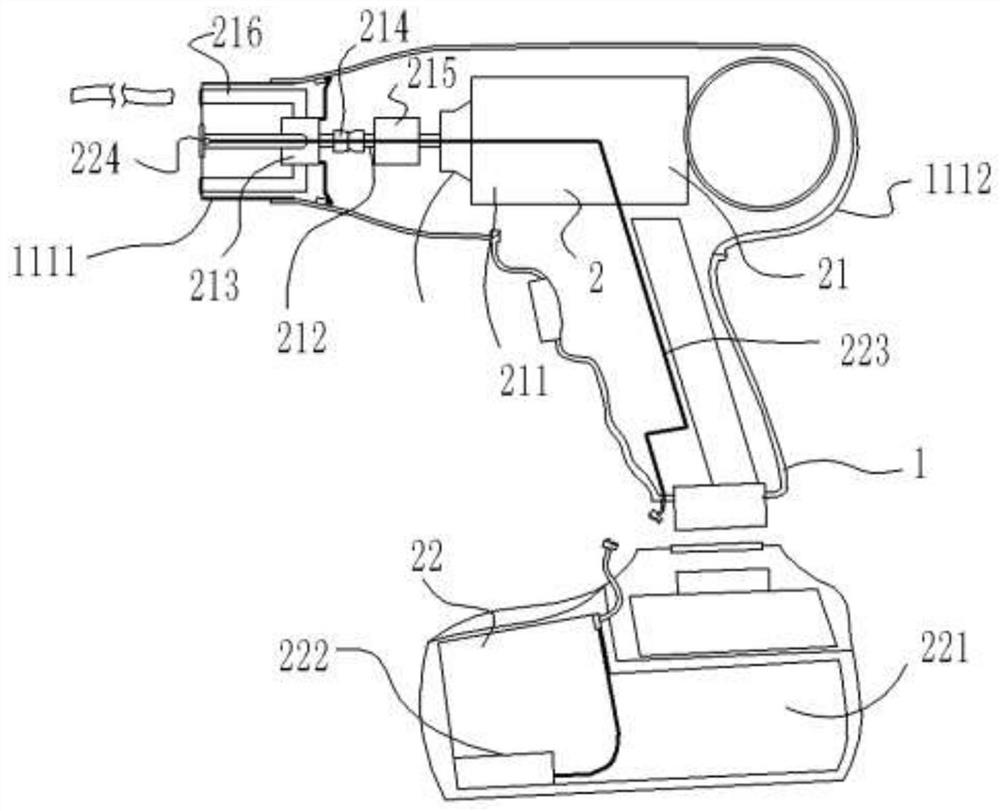

[0032] Embodiment 1: A new type of portable wire harness connector sealing test equipment, including a housing unit 1, a test unit 2 installed inside the hand-held housing 1, and a control unit for connecting with the test unit 2; the housing unit 1 It includes a first housing 11 and a second housing 12 capable of snapping into the first housing 11;

[0033] The test unit 2 includes an air source module 21 for inflating the wire harness connector to be tested, and a spraying module 22 for auxiliary observation of the inflated wire harness connector to be tested;

[0034] The gas source module 21 includes a booster air pump 211 for providing gas to the wiring harness connector to be tested, a gas pipeline 212 that can be connected to the booster gas pump 211 at one end, and a manifold 213 connected to the other end of the gas pipeline 212. On the gas pipeline 212, a check valve 214 for gas backflow is placed, and an air pressure sensing module 215 for sensing gas pressure is in...

Embodiment 2

[0045] Embodiment 2: A new type of portable wire harness connector sealing test equipment, including a housing unit 1, a test unit 2 installed inside the hand-held housing 1, and a control unit for connecting with the test unit 2; the housing unit 1 It includes a first housing 11 and a second housing 12 capable of snapping into the first housing 11;

[0046] The test unit 2 includes an air source module 21 for inflating the wire harness connector to be tested, and a spraying module 22 for auxiliary observation of the inflated wire harness connector to be tested;

[0047] The gas source module 21 includes a booster air pump 211 for providing gas to the wiring harness connector to be tested, a gas pipeline 212 that can be connected to the booster gas pump 211 at one end, and a manifold 213 connected to the other end of the gas pipeline 212. On the gas pipeline 212, a check valve 214 for gas backflow is placed, and an air pressure sensing module 215 for sensing gas pressure is in...

Embodiment 3

[0058] Embodiment 3: The difference from Embodiment 2 is that it also includes an airflow buffer assembly; the airflow buffer assembly uses a buffer airbag; the buffer airbag is installed inside the detection housing 111 , and the buffer airbag is installed on the gas pipeline 212 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com