Sealing performance testing device for sealing ring of dual-drive large-scale wind power main shaft bearing

A wind power spindle and bearing sealing technology, which is used in machine sealing ring testing, liquid/vacuum testing for liquid tightness, wind power generation, etc. , the disassembly process is cumbersome, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

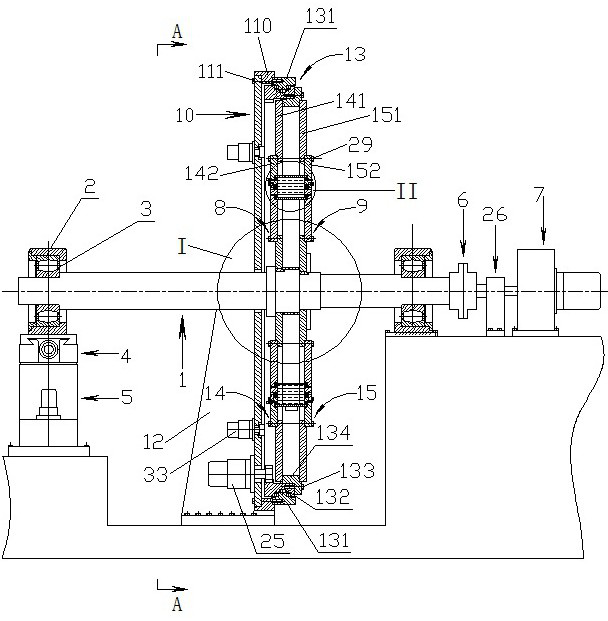

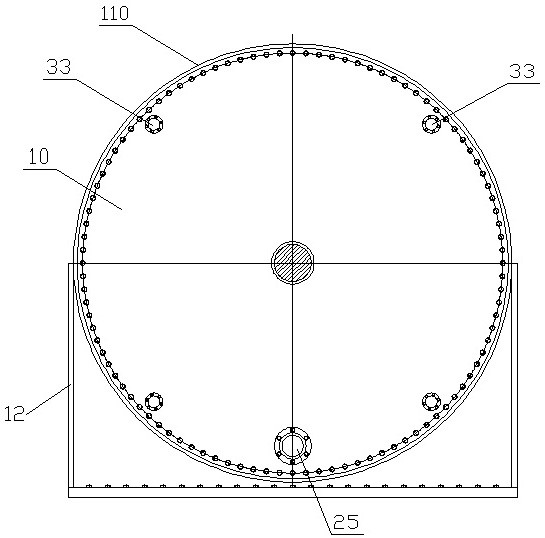

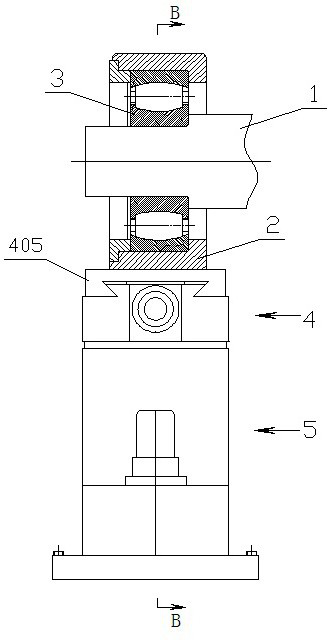

[0022] see figure 1 - Figure 8 , the double-drive large-scale wind power main shaft bearing sealing ring sealing performance test device of the present invention has a horizontal main shaft 1, and the left and right ends of the main shaft are respectively equipped with self-aligning bearings 3 through split bearing housings 2, wherein the split type on the left end The bottom of the bearing seat is equipped with a horizontal moving workbench 4. The split bearing seat can move forward and backward horizontally on the horizontal moving workbench. The front and rear horizontal movement of the split bearing seat can drive one end of the main shaft to move forward and backward accordingly. After the horizontal movement, the bottom of the horizontal movement workbench 4 is equipped with a vertical movement workbench 5. The horizontal movement workbench can move up and down in the vertical direction on the vertical movement workbench. Moving up and down can drive one end of the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com