Connecting structure for concrete pipe pile installation

A technology for concrete pipe piles and connection structures, which can be used in foundation structure engineering, sheet pile walls, buildings, etc., and can solve problems such as trouble, easy corrosion of connection components, installation and transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

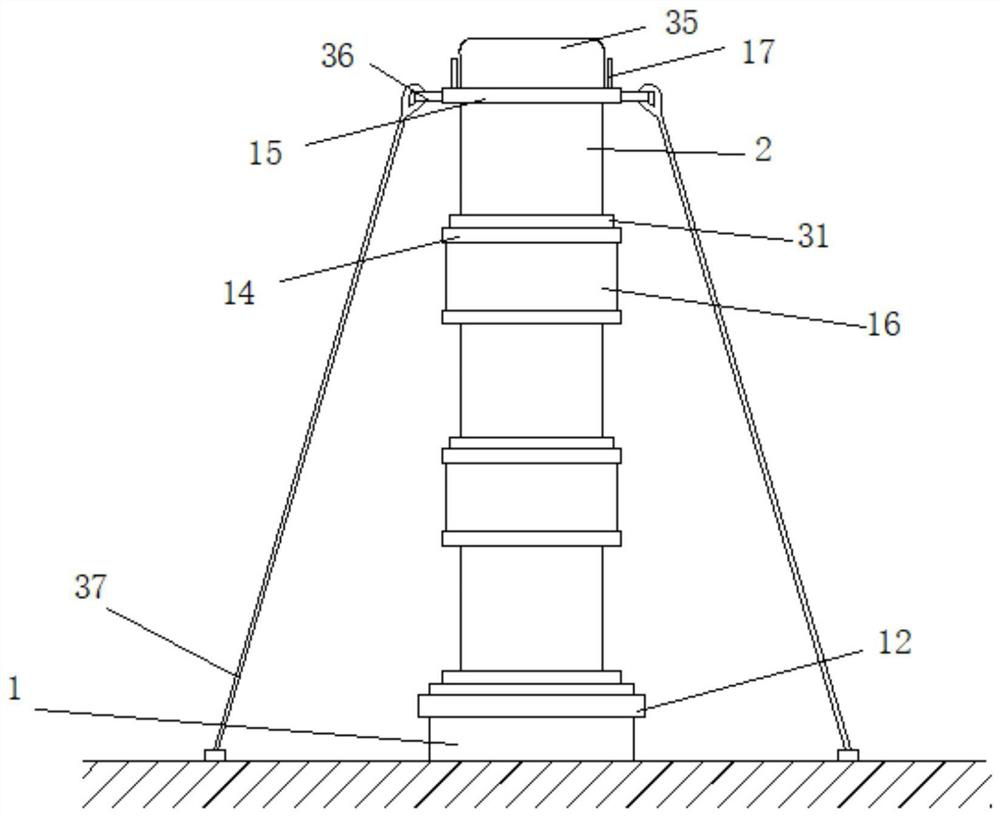

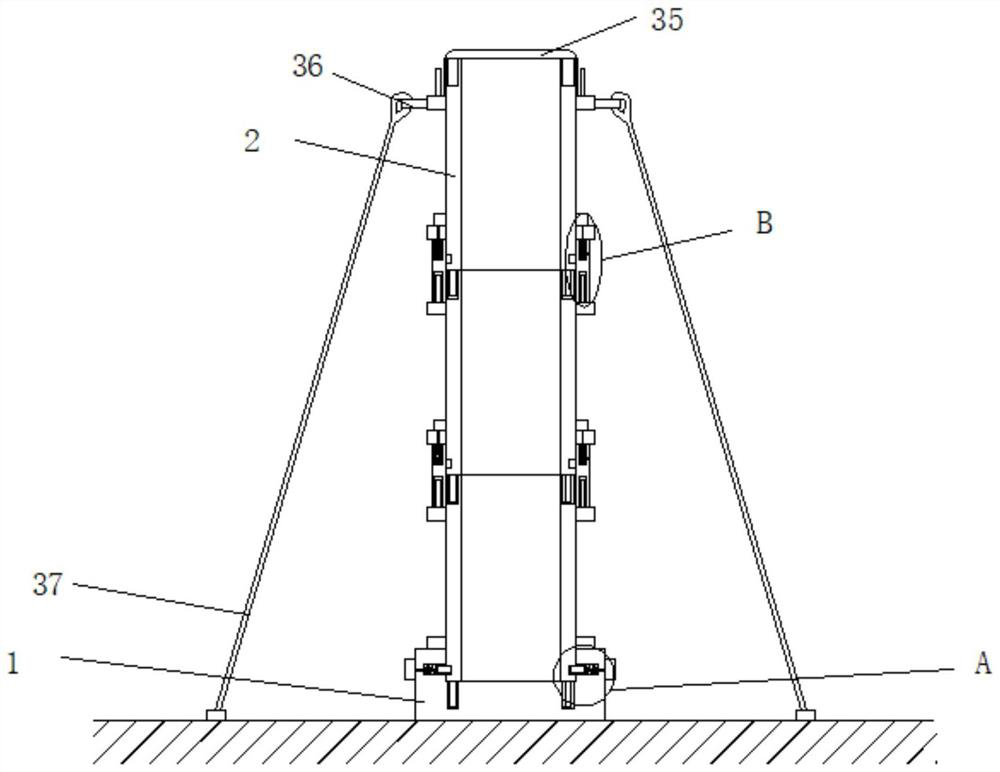

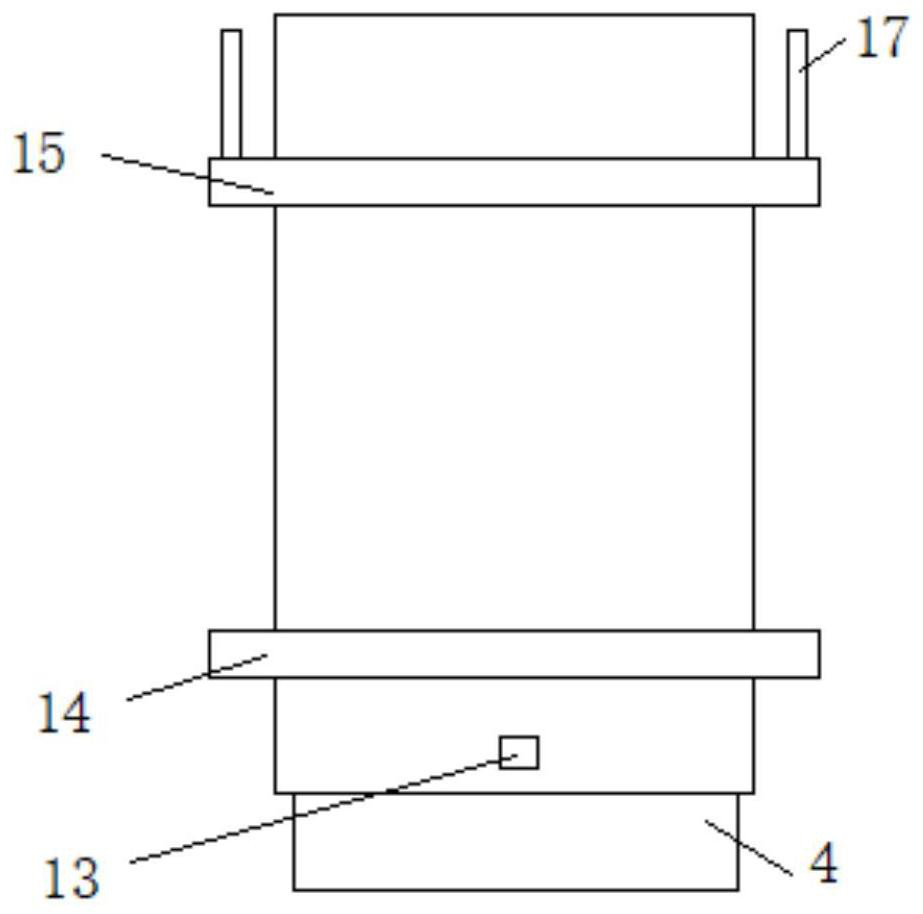

[0032] Embodiment one, such as Figure 1-9 As shown, a connection structure for the installation of concrete pipe piles, including a horizontal installation base 1, the installation base 1 is fixedly connected to the ground, the installation base 1 is a half-open cylinder, and the installation base 1 is vertically arranged A plurality of concrete pipe piles 2, the concrete pipe piles 2 are annular, the bottom surfaces of the plurality of concrete pipe piles 2 are all provided with first connecting grooves 3, and the upper surfaces of the plurality of concrete pipe piles 2 are all fixedly connected with connecting rings 4, the second A connection groove 3 is annular to match the connection ring 4, and a plurality of concrete pipe piles 2 are connected end to end, and the inner bottom surface of the installation base 1 is provided with a second connection groove 5, and the second connection groove 5 is matched with the connection ring 4 The ring 4 of the lowermost concrete pipe ...

Embodiment 2

[0033] Embodiment two, such as figure 1 , 2, 7, the first clamping mechanism 6 includes a groove 7 arranged on the inner surface of the side wall of the installation base 1, and a vertical sliding piece 8 is slidably connected in the groove 7, and the sliding piece 8 faces the port of the groove 7. One side is fixedly connected with the first block 9, and the sliding piece 8 is fixedly connected with the inner wall of the groove 7 through the first spring 10 arranged horizontally. The inner surface of the sliding piece 8 is fixedly connected with a steel wire 11, and the first spring 10 is wound on the steel wire. 11, the steel wire 11 runs through the side wall of the installation base 1 and is slidably connected with it. The first pull ring 12 is sleeved on the outside of the installation base 1. The first pull ring 12 is fixedly connected with multiple steel wires 11, and multiple concrete pipe piles 2 The outer surface is provided with a first card slot 13 that fits with ...

Embodiment 3

[0034] Embodiment three, such as Figure 1-5 As shown, the lower ends of the outer walls of a plurality of concrete pipe piles 2 are fixedly connected with a first fixing ring 14, and the upper ends of the outer walls of a plurality of concrete pipe piles 2 are fixedly connected with a second fixing ring 15, and the first fixing ring 14 at the top is connected with the first fixing ring 14 at the bottom. A fixing ring 16 is arranged between the second fixing ring 15 of the second fixing ring 16, and the fixing ring 16 is in contact with the first fixing ring 14 and the second fixing ring 15 above and below, and the fixing ring 16 is sleeved at the joint of the two concrete pipe piles 2 , the fixing ring 16 is slidingly connected with the two concrete pipe piles 2, the upper surfaces of multiple second fixing rings 15 are all fixedly connected with a plurality of vertically arranged fixing columns 17, and the lower surfaces of the plurality of fixing rings 16 are all provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com